A kind of porphyry copper-molybdenum ore collector and its preparation method and application

A porphyry copper and collector technology, applied in the field of porphyry copper-molybdenum ore collector and its preparation, can solve problems such as adverse effects, unfavorable backwater reuse, protection of mine environment and ecological safety hazards, and achieve environmental protection good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

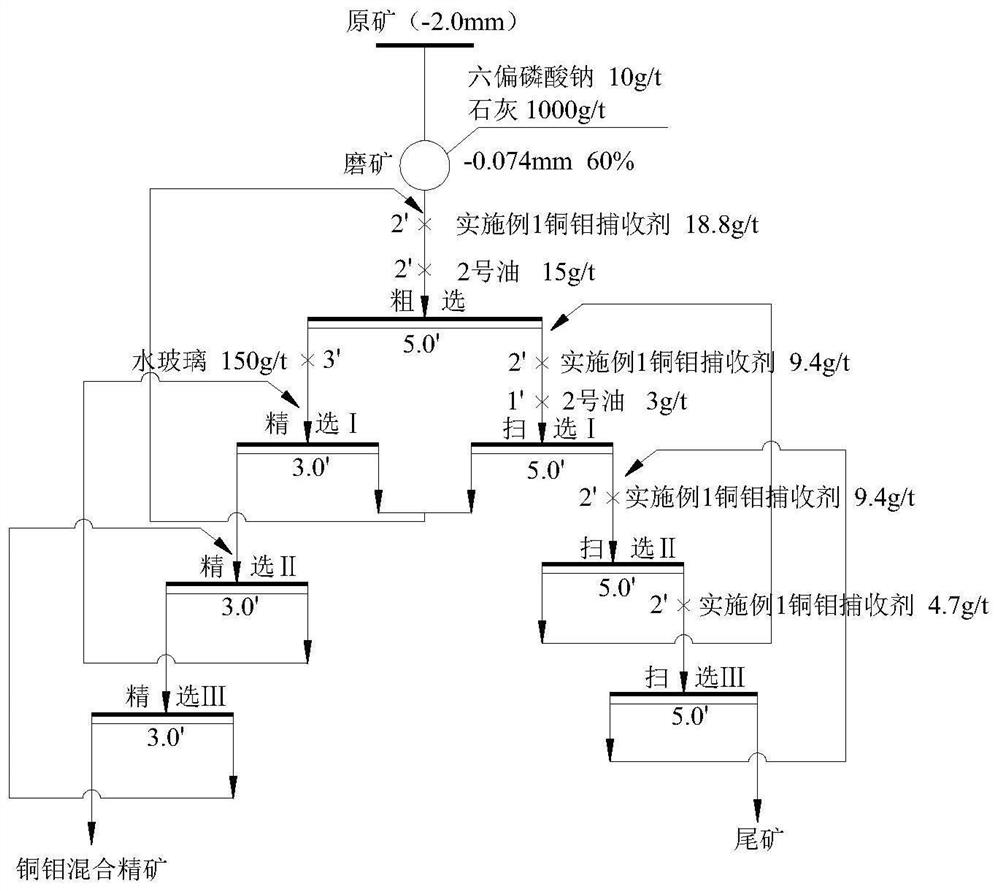

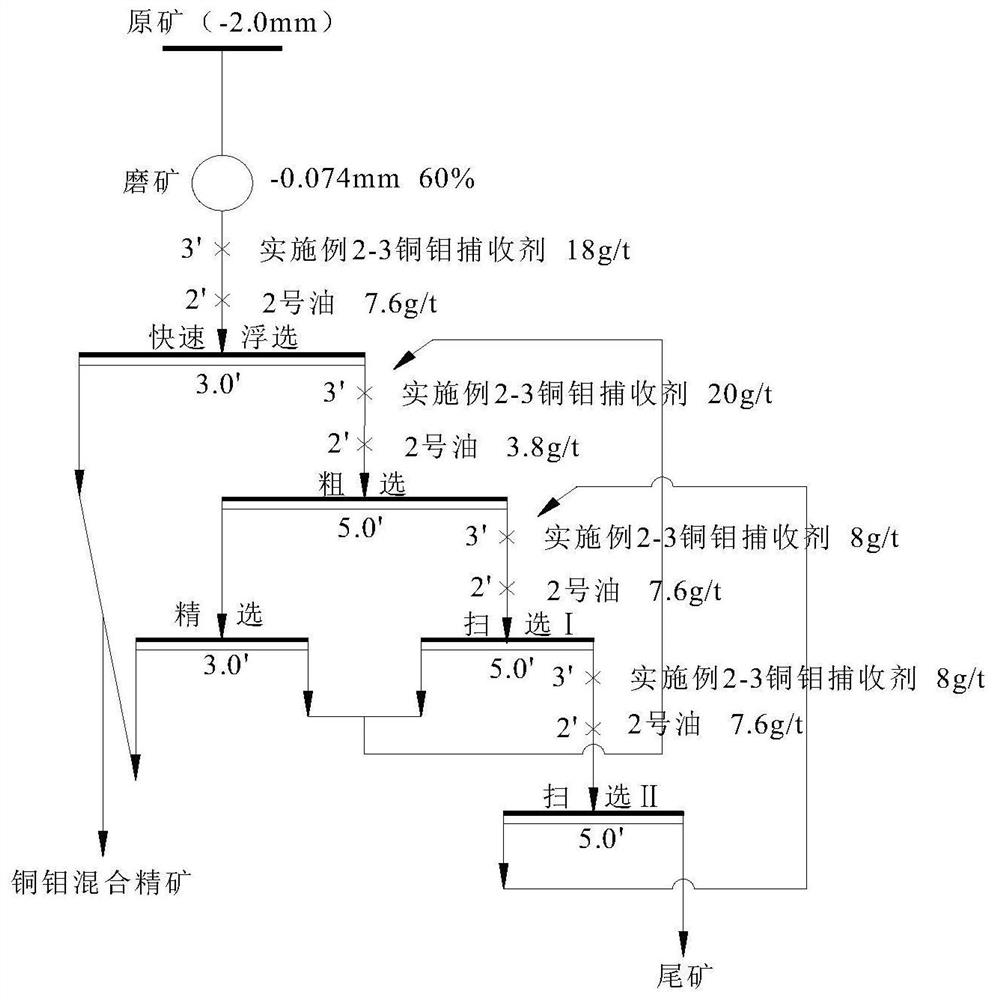

Examples

preparation example Construction

[0044] The present invention also provides the preparation method of the porphyry copper-molybdenum ore collector described in the above-mentioned technical scheme, comprises the following steps: the phthalate of glycol or ethers, heavy oil, hydrocarbon oil and thiocarbamate Ester is mixed to obtain porphyry copper-molybdenum ore collector. In the present invention, there is no special limitation on the mixing sequence of the phthalates, heavy oil, hydrocarbon oil and thiocarbamate of the dihydric alcohols or ethers, and any mixing sequence can be used. In the present invention, the mixing method is not particularly limited, and a mixing method well known to those skilled in the art can be used. In the present invention, the mixing method is preferably stirring; the mixing time is preferably 5-15 minutes. The present invention forms a homogeneous, transparent and oily porphyry copper-molybdenum ore collector through the mixing, ensures the homogeneity and stability of the por...

Embodiment 1

[0048] Bis(diethylene glycol monobutyl ether) phthalate was purchased from Shanghai Zhangjiang Sandia Custom Synthesis Company.

[0049] At room temperature, add 12 mL of bis(diethylene glycol monobutyl ether) phthalate, 40 mL of heavy oil, 36 mL of kerosene and 12 mL of N-allyl-O-isobutyl thiocarbamate into four ports In the reaction bottle, there is no requirement for the order of addition, and a 60-watt electric stirrer is used to stir for 10 minutes to obtain a homogeneous, transparent oily substance, which is to obtain the porphyry copper-molybdenum ore collector.

Embodiment 2

[0051] Bis(triethylene glycol monoethyl ether) phthalate was purchased from Shanghai Zhangjiang Sandia Custom Synthesis Company.

[0052] At room temperature, mix 10 mL of bis(triethylene glycol monoethyl ether) phthalate, 40 mL of heavy oil, 37 mL of kerosene, 5 mL of N-ethyl-O-isopropylthiocarbamate and 8 mL of N- Allyl-O-isobutyl thiocarbamate was added to a four-necked reaction flask, and stirred for 10 minutes using a 60-watt electric stirrer to obtain a homogeneous, transparent oil, which was poured out and bottled to obtain the described Porphyry copper molybdenum ore collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com