Fabricated overhead leveling floor heating module and production method and mounting method thereof

A prefabricated, flat ground technology, applied in the direction of buildings, building structures, floors, etc., can solve the problems of increasing building load, height adjustment, waste of space operation, etc., to improve load-bearing and impact resistance, and improve stability And the effect of load-bearing and improving the effect of heat conduction and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

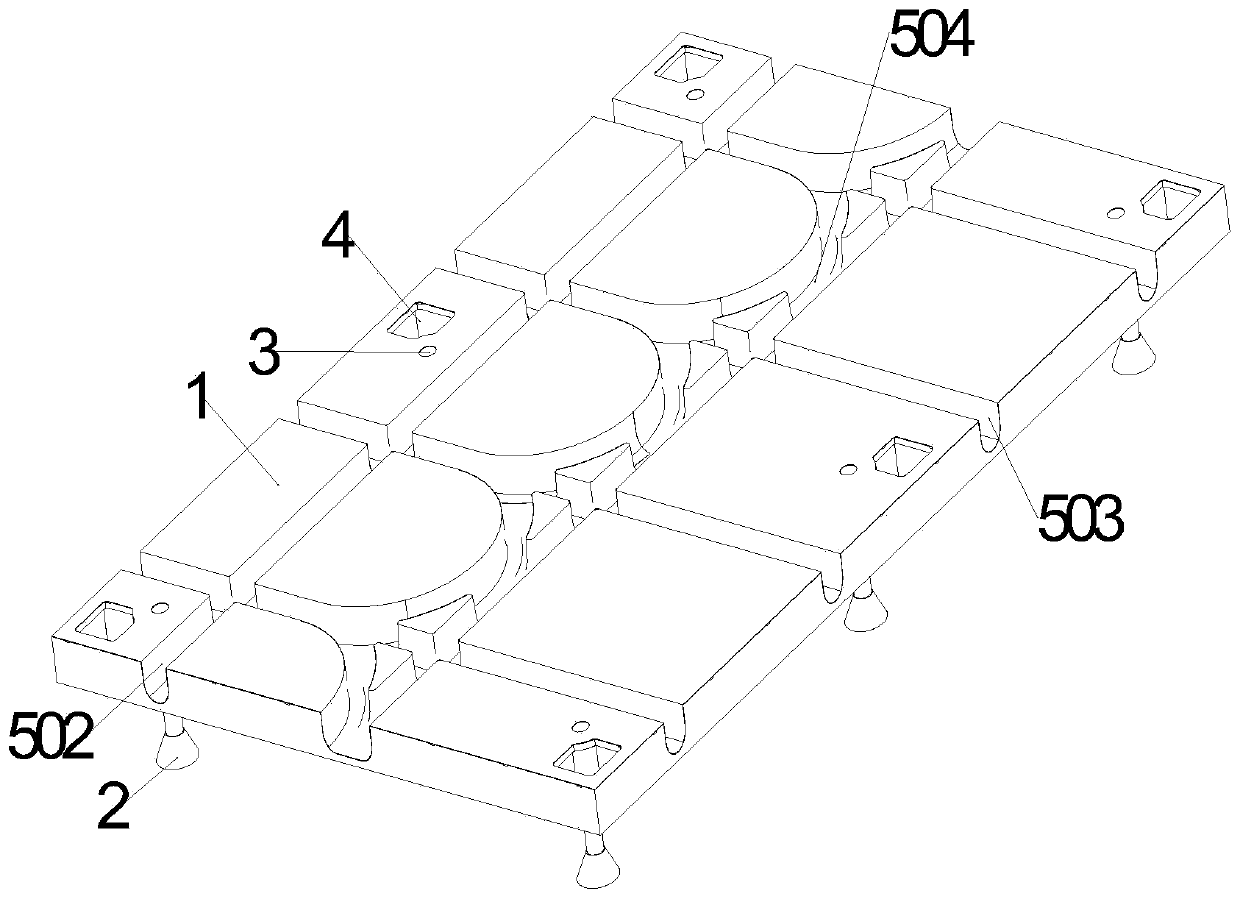

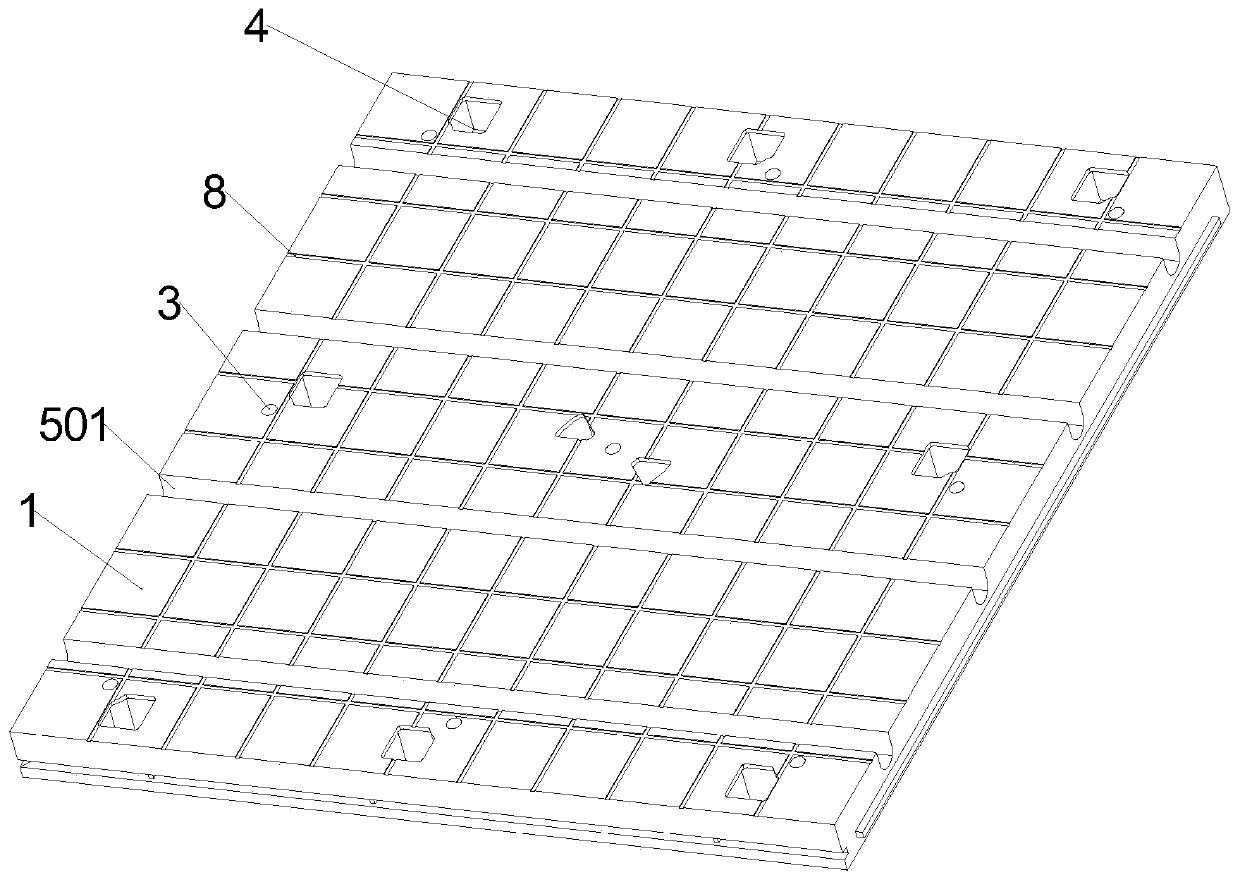

[0066] Please refer to Figure 1-12 , this embodiment provides an assembled overhead leveling floor heating module, including a load-bearing pavement panel 1 and an adjustable support assembly 2;

[0067] The load-bearing pavement panel 1 consists of a nano-carbon crystal layer 101, a reflective heat-conducting layer 102 and a base layer 103 from top to bottom. The nano-carbon crystal layer 101 is sprayed on the surface of the reflective heat-conducting layer 102, and the reflective heat-conducting layer 102 is matched and pressed on the base layer 103 surfaces;

[0068] The side of the load-bearing pavement panel 1 is provided with a splicing mechanism. In this embodiment, the splicing mechanism is a mortise and tenon structure with mutually matching shapes arranged along the diagonal sides of the load-bearing pavement panel 1. One side of the load-bearing pavement panel is provided with a first male The tongue 104 and the second female tongue groove 105 are matched with the...

Embodiment 2

[0085] The present embodiment provides a method for preparing the base layer of the load-bearing pavement panel as in embodiment 1, comprising the following steps:

[0086] Prepare the following component raw materials by weight:

[0087] a. Prepare the following component raw materials by weight: 20-30 parts of alkali-free glass fiber, 11-15 parts of calcium powder, 5-10 parts of aluminum hydroxide, 1-3 parts of lanthanum oxide, 2-3 parts of processing aid, 60-70 parts of phenolic modified PPA resin, 15-20 parts of quartz fiber twill fabric, 1.5-2.5 parts of silane coupling agent, 1-2 parts of hydroxyquinoline aluminum, 40-50 parts of bisphenol A cyanate, 1-2 parts of toughening agent, 10-12 parts of epoxy resin, 6-8 parts of polyphenol oxygen resin;

[0088] The phenolic modified PPA resin is composed of m-diethynylbenzene and p-diethynylbenzene ablation phenolic formaldehyde according to the weight ratio of 4:1;

[0089] Described toughening agent is to take n-butyl acryl...

Embodiment 3

[0096] This embodiment provides a method for installing the assembled overhead leveling floor heating module as in Embodiment 1, including the following steps:

[0097] a. Clean up the concrete floor sanitation, remove dust, and spray ground solid paint;

[0098] b. Measure the size of the house area, match the load-bearing pavement panels and the type and quantity of adjustable support components according to different areas, and match the straight groove load-bearing pavement panels in the load-bearing pavement panels according to the laying shape of the floor heating pipeline and the number of reversible load-bearing pavement panels;

[0099] c. Put horizontal lines. On both sides of the front and rear directions of the installation sequence, place a parallel horizontal line according to the preset overhead height, draw a sliding horizontal line between the two parallel lines, and slide in the direction of non-installation according to the advancement of the installation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com