Antibacterial formaldehyde-removing coating and preparation method thereof

A formaldehyde and coating technology, applied in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of not reaching the ideal effect, producing harmful substances, poor durability, etc., to avoid adsorption saturation and secondary Less pollution, good stability, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The present invention also provides a method for preparing the antibacterial and formaldehyde-removing coating according to any of the above technical solutions, comprising the following steps:

[0094] A1 Preparation of prepolymer

[0095] Remove water from polyether polyol, pass nitrogen, add butanone and polyisocyanate, heat, add catalyst to the system dropwise, after reacting for 1-3 hours, add the first chain extender and the second chain extender in sequence, and continue the reaction for 2- 4h, obtain described prepolymer;

[0096] A2 prepares polyurethane aqueous dispersion

[0097] Cool down the prepolymer prepared in step A1, add a neutralizing agent to neutralize, react for 30-40min, add acetone and stir to adjust the viscosity, add water and stir to obtain a polyurethane aqueous dispersion;

[0098] Preparation of A3 functional dispersion

[0099] Add the formaldehyde-removing agent, activated bamboo charcoal powder, and antibacterial agent to acetone, si...

Embodiment 1

[0111] A1 Preparation of prepolymer

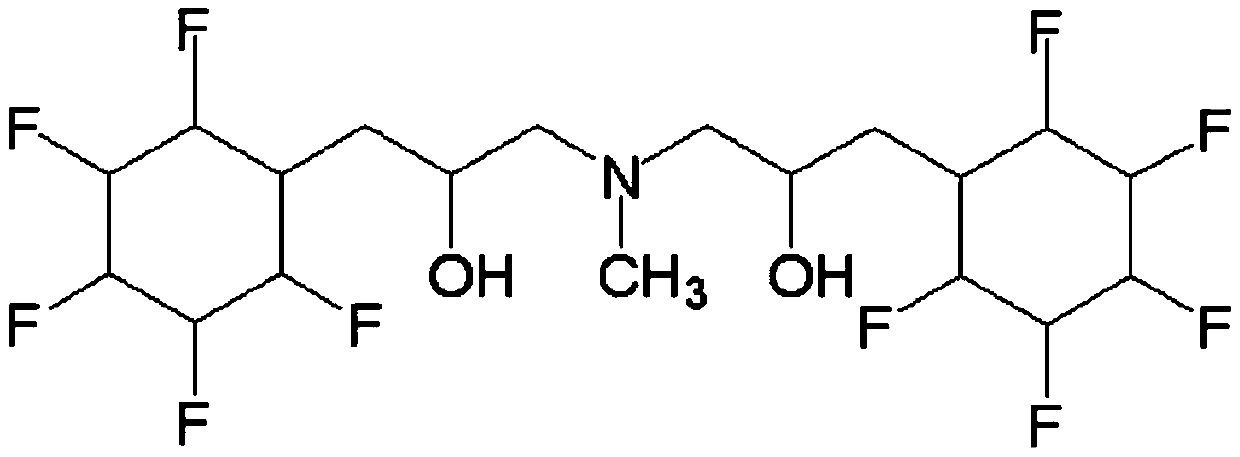

[0112] Remove water from the mixture (68g / 32g) of N,N-di(2-hydroxy-3-perfluorohexyl-propyl)methylamine and polytetrahydrofuran ether diol, blow nitrogen, add methyl ethyl ketone and isophorone Heat isocyanate (80g), add a mixture of titanium trichloride and triethylaluminum (0.046g / 0.024g) dropwise to the system, after reacting for 1-3h, add 1,2-dihydroxy-3-propanesulfonic acid in sequence Sodium (4g) and 1,4-butanediol (10g) continued to react for 4h to obtain the prepolymer;

[0113] A2 prepares polyurethane aqueous dispersion

[0114] Cool down the prepolymer prepared in step A1, add neutralizing agent triethylamine (10g) to neutralize, the reaction temperature is 80°C, react for 30-40min, add acetone and stir to adjust the viscosity, add water and stir to obtain Aqueous polyurethane dispersion;

[0115] Preparation of A3 functional dispersion

[0116] Add the pure mixture of nano-layered zirconium phosphate and diatom (4g / 16g), act...

Embodiment 2

[0120] A1 Preparation of prepolymer

[0121] Remove water from the mixture (52g / 22g) of N,N-di(2-hydroxy-3-perfluorohexyl-propyl)methylamine and polytetrahydrofuran ether diol, blow nitrogen, add butanone, toluene diisocyanate (70g ), heating, and dropwise adding a mixture of titanium trichloride and triethylaluminum (0.045g / 0.020g) to the system, after reacting for 2h, adding dimethylolpropionic acid (7g) and 1,4-cyclohexane Dimethanol (10g), continue to react 3h, obtain described prepolymer;

[0122] A2 prepares polyurethane aqueous dispersion

[0123] Cool down the prepolymer prepared in step A1, add neutralizing agent triethanolamine (8g) to neutralize, the reaction temperature is 70°C, react for 30-40min, add acetone and stir to adjust the viscosity, add water and stir to obtain polyurethane water dispersion;

[0124] Preparation of A3 functional dispersion

[0125] Add the pure mixture of nano-layered zirconium phosphate and diatoms (4g / 7g), activated bamboo charcoal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com