Subgrade reinforcing quick-setting grouting material and preparation method thereof

A grouting material and reinforcement technology, which is applied in the field of roadbed grouting materials, can solve problems such as poor working performance, high price, and high energy consumption in production, and achieve the effects of good fluidity, high calculus rate, and increased utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

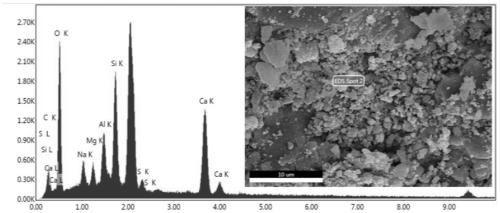

Image

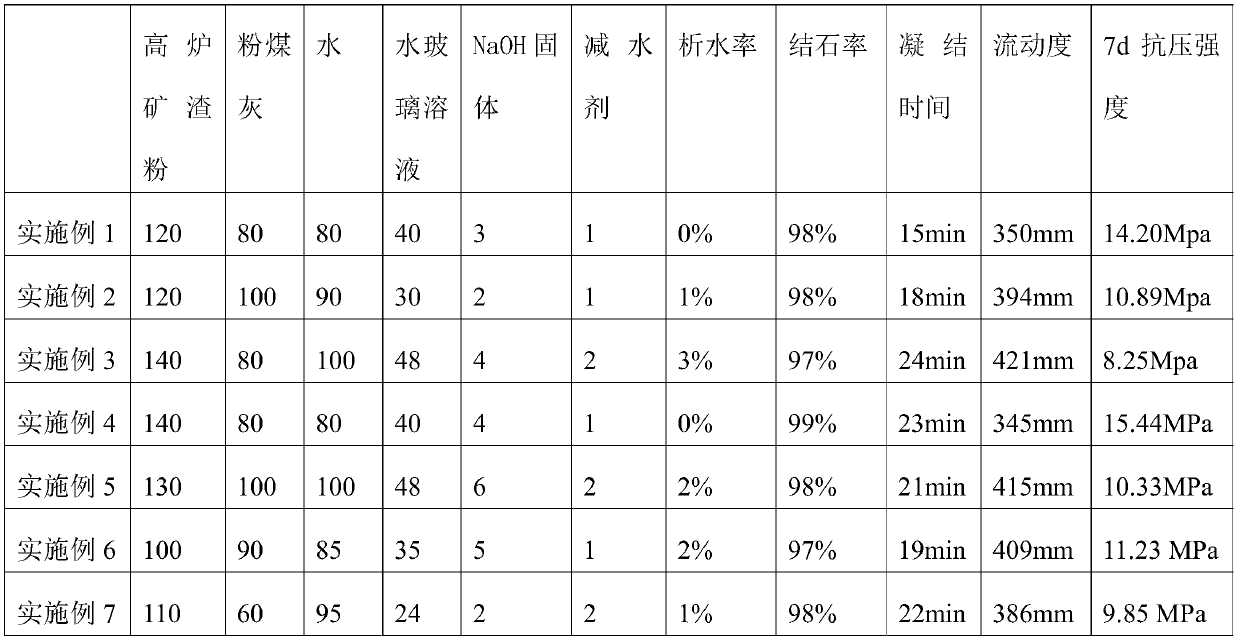

Examples

preparation example Construction

[0030] A kind of preparation method of subgrade reinforcement quick-setting grouting material of the present invention comprises following specific steps:

[0031] Step 1), prepare B solution: mix the weighed water glass solution and NaOH solid until NaOH is completely dissolved to obtain B solution, since the NaOH solid dissolves in the water glass solution and will release heat, it needs to be stirred slowly when stirring;

[0032] Step 2), mix the above-mentioned blast furnace slag powder and fly ash that have been weighed uniformly, then put water reducing agent and water into the uniformly mixed blast furnace slag powder and fly ash and stir to obtain the A mixture, specifically, add Stir the water reducer and water at 50-100r / min for at least 5min, then at 200-300r / min for at least 5min to obtain the A mixture;

[0033] Step 3), mix B solution and A mixture evenly to obtain roadbed reinforcement quick-setting grouting material; specifically, pour B solution into A mixtur...

Embodiment 1

[0035] Step 1), get the following raw materials by mass fraction:

[0036] 120 parts of blast furnace slag powder above S95 grade, 80 parts of F grade fly ash, 90 parts of water, 40 parts of water glass solution, 3 parts of NaOH solid, and 1 part of water reducer.

[0037] Step 2), pour the weighed NaOH solid into the water glass solution and stir until the NaOH is completely dissolved to obtain the B solution;

[0038] Step 3), dry-mix the weighed blast furnace slag powder and fly ash in a mixer, then add water reducing agent and water in turn, stir at 100r / min for 5min, then stir at 200r / min for 7min, and obtain A mixture;

[0039] Step 4), mix solution B and mixture A, and stir at 300 r / min for 2 minutes to obtain a grouting material.

[0040] Use the grouting pressure pump and the grouting pipe to inject the prepared grouting material into the designated area for grouting filling. Then the performance of the grouting material was tested, and the performance of the grout...

Embodiment 2

[0043] Step 1), get the following raw materials by mass fraction:

[0044] 120 parts of blast furnace slag powder above S95 grade, 100 parts of F grade fly ash, 80 parts of water, 30 parts of water glass solution, 2 parts of NaOH solid, 2 parts of water reducer;

[0045]Step 2), pour the weighed NaOH solid into the water glass solution and stir until the NaOH is completely dissolved to obtain the B solution;

[0046] Step 3), dry mix the weighed blast furnace slag powder and fly ash in a mixer, then add water reducer and water in turn, stir at 50r / min for 8min, then stir at 300r / min for 5min, to obtain A mixture;

[0047] Step 4), mix solution B and mixture A, and stir at 300 r / min for 2 minutes to obtain a grouting material.

[0048] Use the grouting pressure pump and the grouting pipe to inject the prepared grouting material into the designated area for grouting filling. Then the performance of the grouting material was tested, and the performance of the grouting material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clotting time | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com