Preparation method of copper-silver micro-nano composite layer material

A micro-nano, composite layer technology, applied in the field of electrochemistry, can solve problems such as product shape and area limitation, and achieve the effects of low manufacturing cost, large surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

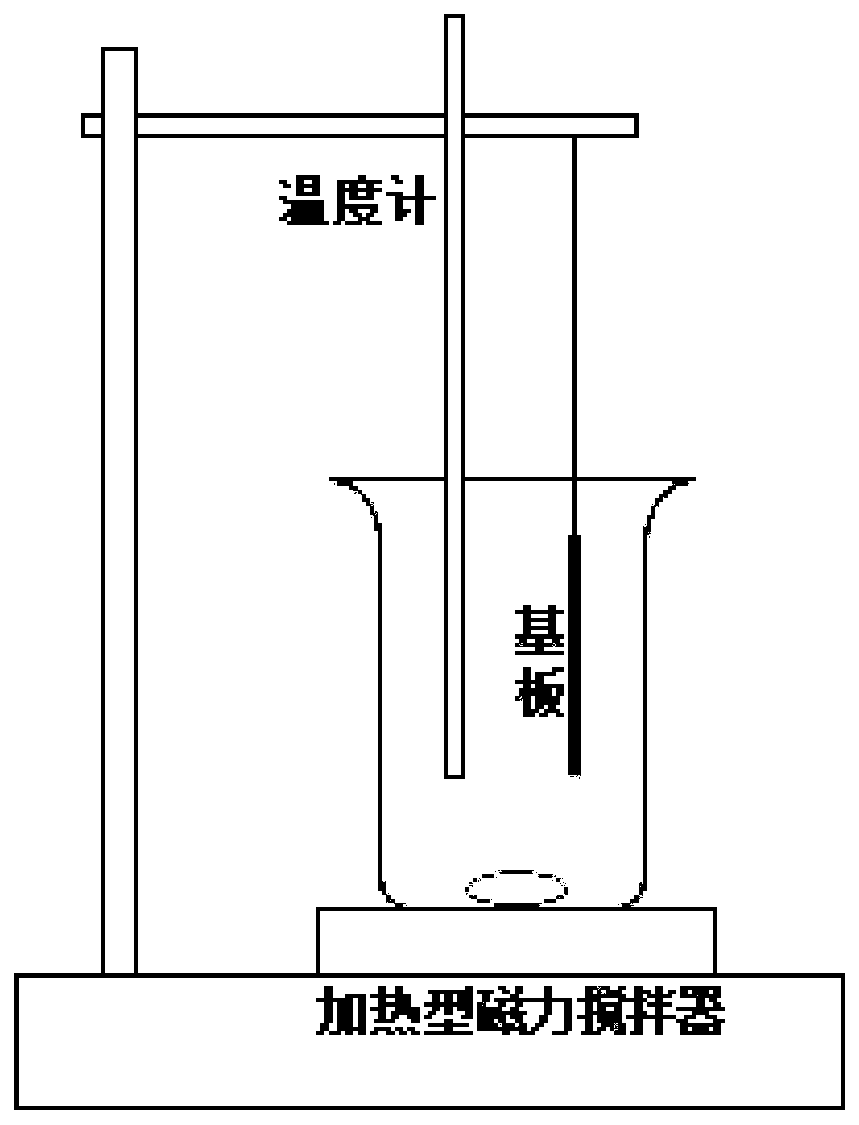

Method used

Image

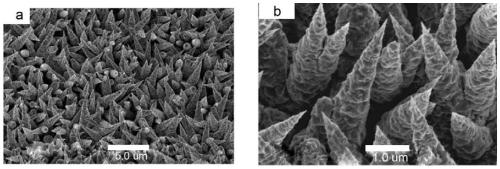

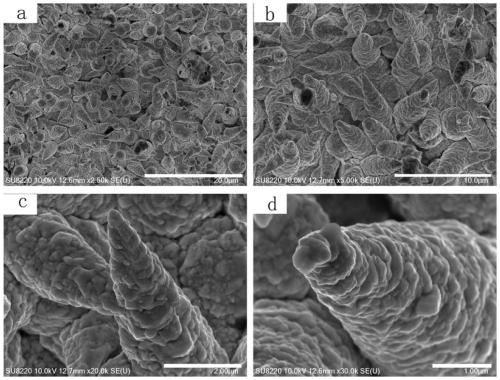

Examples

Embodiment 1

[0029] As a method for preparing a copper-silver micro-nano composite layer material according to an embodiment of the present invention, the method comprises the following steps:

[0030] (1) Provide C194 copper alloy as the substrate with a thickness of 0.25mm and a size of 50mm×70mm, and the current density of the substrate is 5A / dm 2 Electrodegreasing for 60s, then pickling in 10% sulfuric acid for 30s, and then in 0.2g / L PdCl 2 Activation in solution for 60s;

[0031] (2) Submerge the base material treated in step (1) in the copper needle layer plating solution at 65° C. to electroless deposit the copper needle layer, wherein the copper needle layer plating solution consists of 0.06mol / L copper sulfate, 0.013mol / L nickel sulfate, 0.48mol / L boric acid, 0.28mol / L sodium hypophosphite, 0.09mol / L trisodium citrate, 1g / L polyethylene glycol and sodium hydroxide, hydrogen Sodium oxide is used to adjust the pH of the copper needle layer plating solution to be 9.0-9.5;

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com