Welding process of ultrahigh-strength precipitated hardened stainless steel

A precipitation hardening, ultra-high-strength technology, used in welding equipment, welding media, welding equipment, etc., can solve the problems of poor welding quality and low strength of stainless steel, and achieve the effect of stable welding quality, high strength, and convenient welding or processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

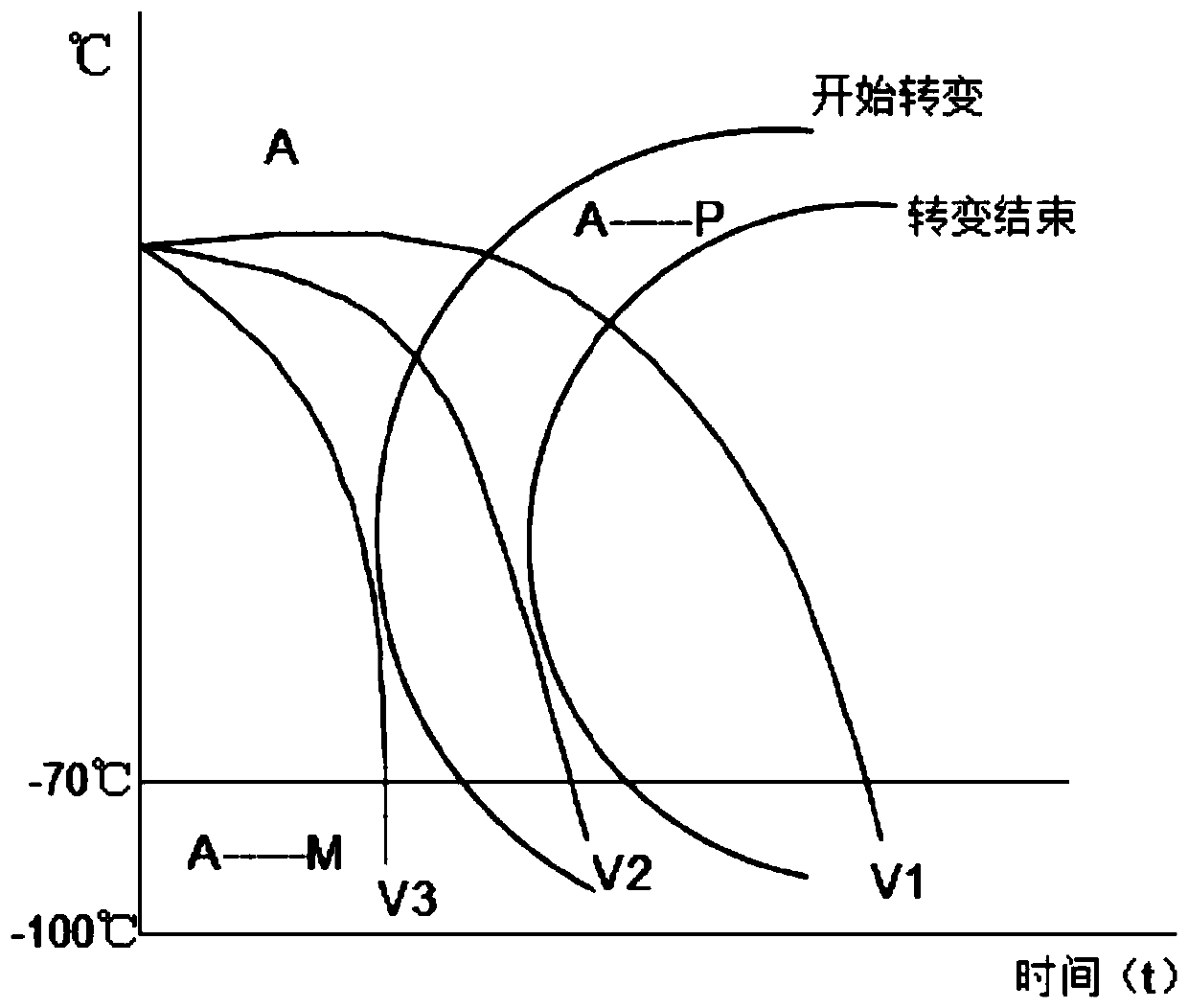

Image

Examples

Embodiment 1

[0043] A welding process for ultra-high-strength precipitation-hardening stainless steel, comprising the steps of:

[0044] (1) Analyze the chemical and mechanical indicators of the welded stainless steel base material and select the welding method; select the welding method according to the analysis of the stainless steel base material, so that the entire welding process is smooth and the welding quality is guaranteed to be good;

[0045] (2) Design of joint bevel; Figure 5 As shown, specifically, the groove angle in the joint groove is 60±2.5°, the butt gap is 2mm, and the single-sided "V" groove setting is adopted without blunt edges, which ensures that the stainless steel base metal can be fully welded when welding , which is convenient for machining and effectively improves the welding quality;

[0046] (3) pre-welding cleaning preparation; preferably, the step (3) includes the following steps:

[0047] (3.1) Clean up impurities: remove the oil and water within 20mm on...

Embodiment 2

[0059] Basically the same as Example 1. In this example, take a stainless steel pressure vessel of a large chemical plant as an example. The material of the stainless steel vessel is 0Cr17Ni7Al, the operating temperature is 200°C, and the wall thickness is δ12; the welding process for the material 0Cr17Ni7Al is as follows:

[0060] (1) Analyze the chemical and mechanical indicators of the welded stainless steel base material and select the welding method; the chemical composition of the 0Cr17Ni7Al base material is shown in Table 1 below, and the mechanical properties of the 0Cr17Ni7Al base material are shown in Table 2 below:

[0061] Table 1 Chemical composition of 0Cr17Ni7Al (%)

[0062] C Si mn S P 0.07-0.10 ≤0.5 0.5-1.0 ≤0.03 ≤0.035 Cr Ni Mo N Al 16.0-18.0 6.5-7.5 0.2-0.3 0.04-0.08 0.75-1.2

[0063] Table 2 Mechanical properties of 0Cr17Ni7Al

[0064] σ0.2(MPa) σb(MPa) δ(%) HRC Ak(J / cm2) ≥1276 ≥1379 ≥9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com