Super arc MIG+ laser double-sided composite high-speed welding method for titanium and aluminum

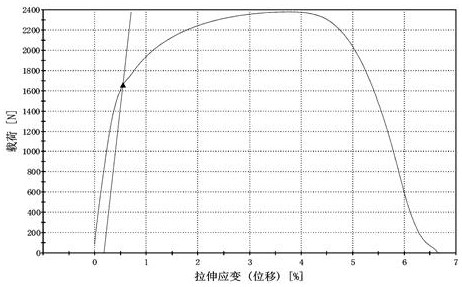

A welding method and super arc technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of high equipment requirements, achieve excellent mechanical properties, reduce equipment requirements, and interface with reliable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

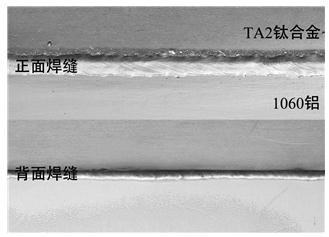

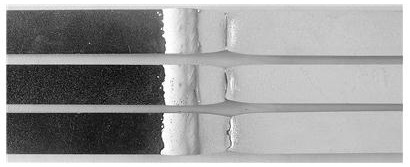

[0030] Embodiment 1: High-speed welding of pure titanium and pure aluminum

[0031] The industrial pure titanium (TA2) plate with a thickness of 2.5mm is butt welded with the industrial pure aluminum (1060) plate with a thickness of 2.5mm. The length of the welded titanium plate and the aluminum plate are both 150mm and the width is 100mm.

[0032] The specific welding process steps are as follows:

[0033] 1) Before welding, use an angle grinder to make a 35°V-shaped groove on the side of the titanium plate, and the blunt side is about 0.2mm;

[0034] 2) Finely grind the surface of the titanium plate to be welded with a wire brush until the metallic luster is completely exposed, then soak it with an aqueous solution of 40% nitric acid and 5% hydrofluoric acid for 3 minutes, and finally rinse it with anhydrous acetone and dry it in the air. First soak the aluminum plate and welding wire with an aqueous solution of 10% sodium hydroxide at 60°C for 3 minutes; after taking it ou...

Embodiment 2

[0039] Embodiment 2: High-speed welding of pure titanium and pure aluminum

[0040] The titanium alloy (TC4) plate with a thickness of 3mm is butt welded with the antirust aluminum alloy (5A06) plate with a thickness of 3mm. The length of the welded titanium plate and the aluminum plate are both 150mm and the width is 100mm.

[0041] The specific welding process steps are as follows:

[0042] 1) Before welding, use an angle grinder to open a 35°V-shaped groove on the side of the titanium plate, and the height of the blunt edge is about 0.3mm;

[0043] 2) Finely grind the surface of the titanium plate to be welded with a wire brush until the metallic luster is completely exposed, then soak it with an aqueous solution of 40% nitric acid and 5% hydrofluoric acid for 3 minutes, and finally rinse it with anhydrous acetone and dry it in the air. First soak the aluminum plate and welding wire with an aqueous solution of 10% sodium hydroxide at 60°C for 3 minutes; after taking it out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com