Welding method for coating main engine cylinder sleeve with zinc plate

A welding method and zinc plate technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult control of welding operation, difficult installation of zinc plate, and unstable quality, so as to achieve stable welding quality and prolong life , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

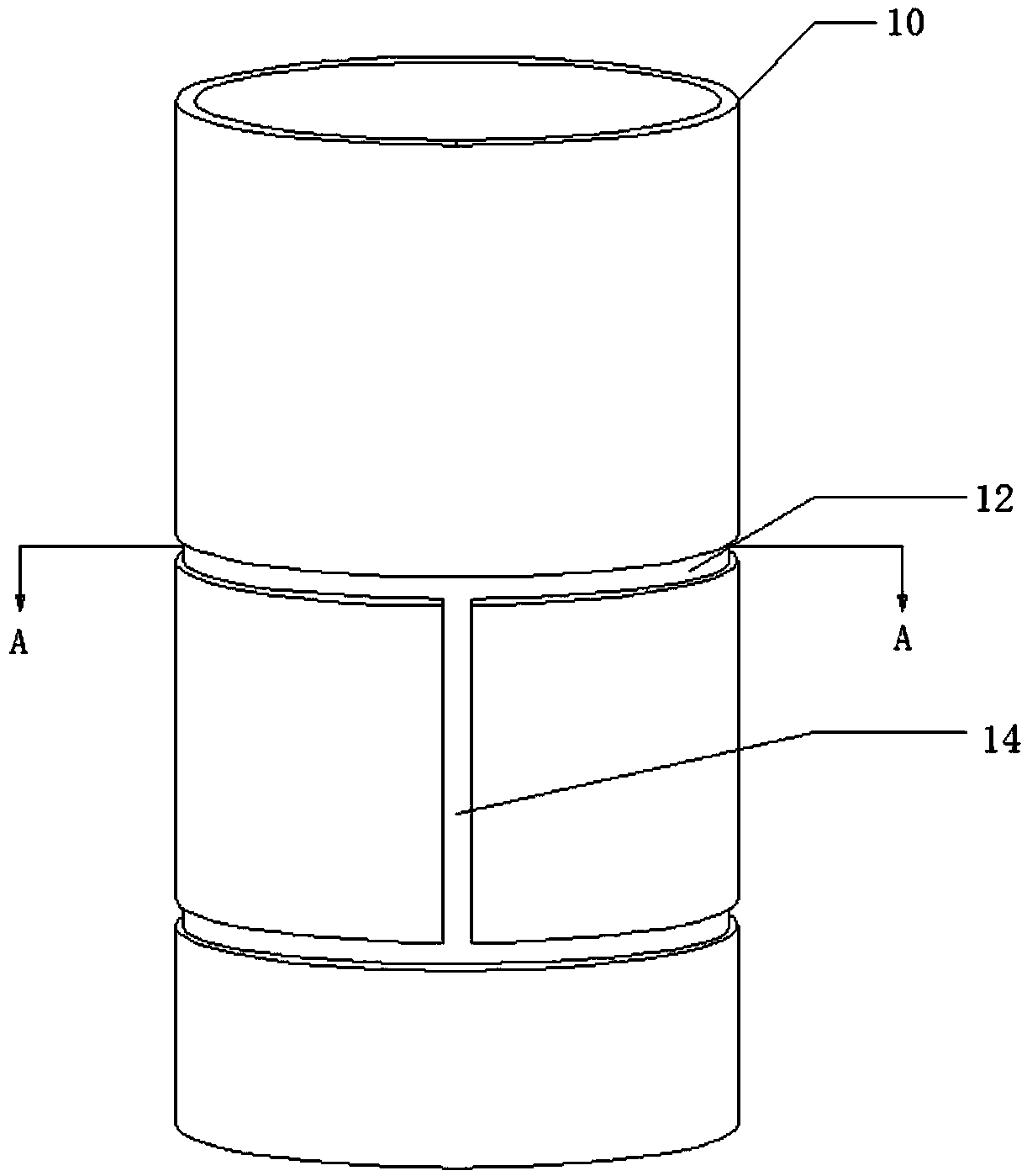

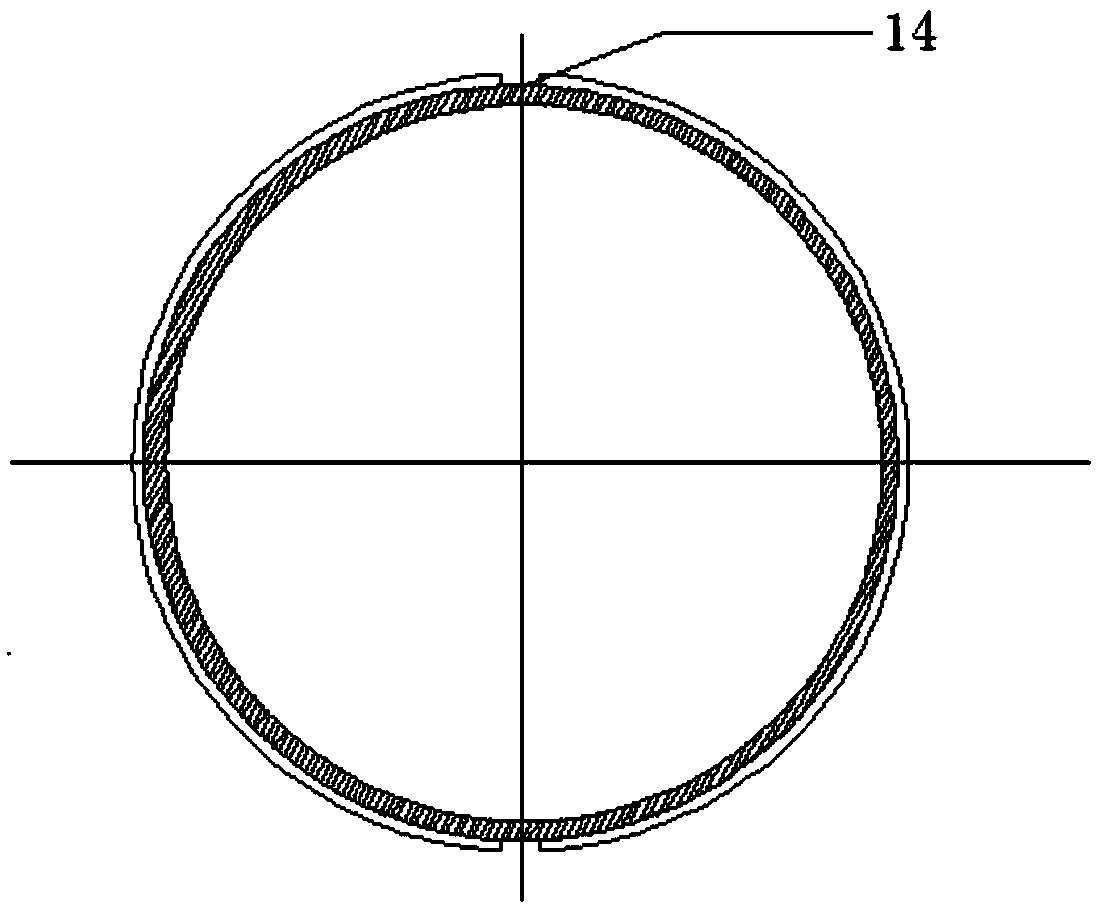

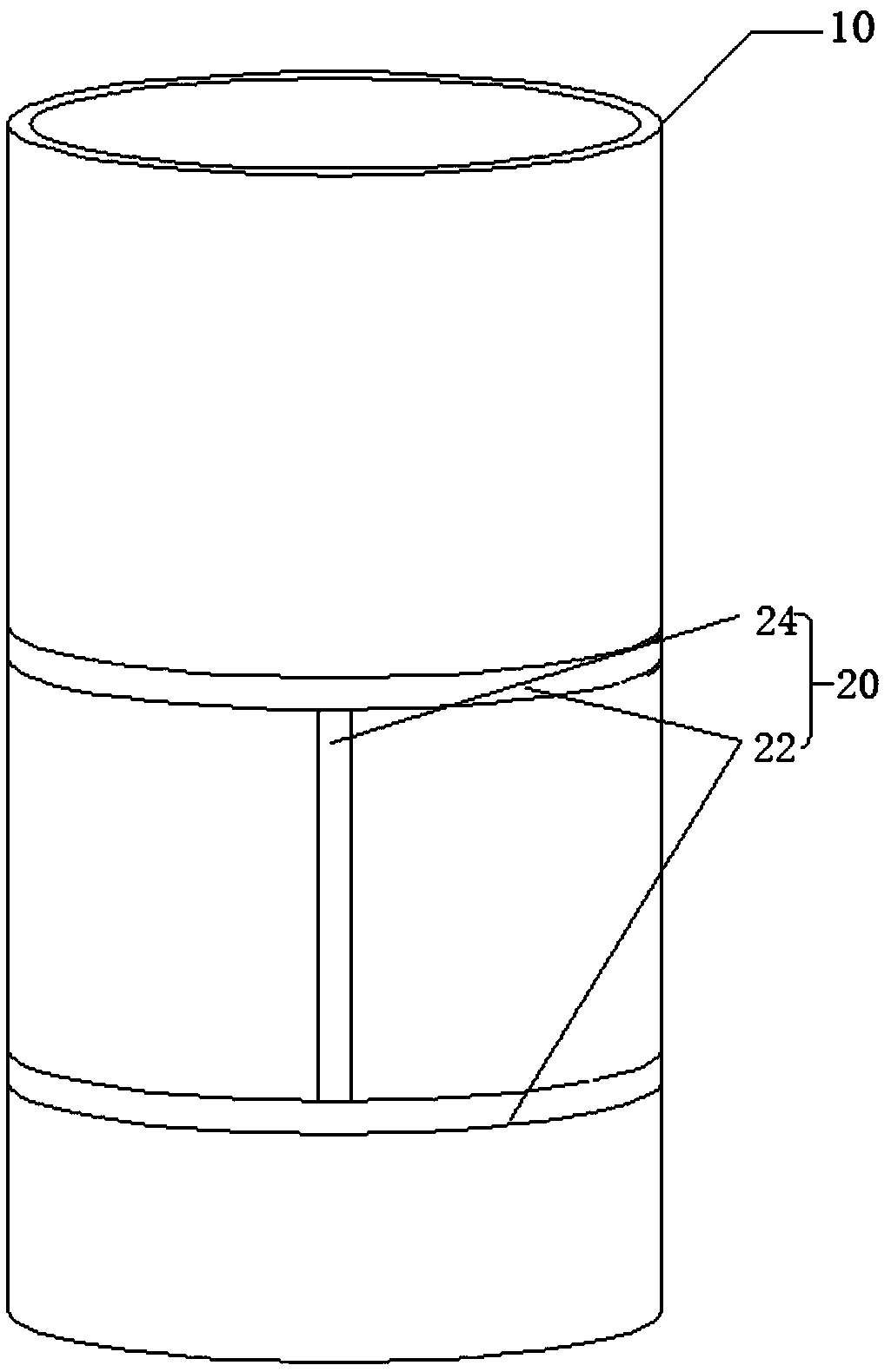

[0031] Please also refer to Figure 1-3 , figure 1 It is a schematic diagram of the piston cylinder liner structure of the main engine, figure 2 It is the A-A sectional view of the piston cylinder liner of the main engine, image 3 It is a schematic diagram of the piston cylinder liner structure of the main engine after welding the zinc plate. An innovative welding method for a main engine cylinder liner wrapped zinc plate described in this embodiment includes the following steps:

[0032] Preparation before S1 welding:

[0033] ① Self-made welding wire: select the zinc plate wrapped with the cylinder liner, and cut the zinc plate into 2-3mm lines with a shearing machine;

[0034] ② Zinc plate surface treatment: Use a wire brush to clean the oxide skin on the surface of the zinc plate to prevent the oxide layer on the surface of the zinc plate from hindering the fusion between the metals;

[0035] ③Strengthen the ventilation of the construction site, and the staff must w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com