Automatic welding method and system for nuclear-grade PE pipe

An automatic welding and pipe fitting technology, applied in the field of nuclear power, can solve the problems of large influence of human factors and low quality reliability, and achieve the effect of obvious superiority, stable welding quality, and elimination of the influence of human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

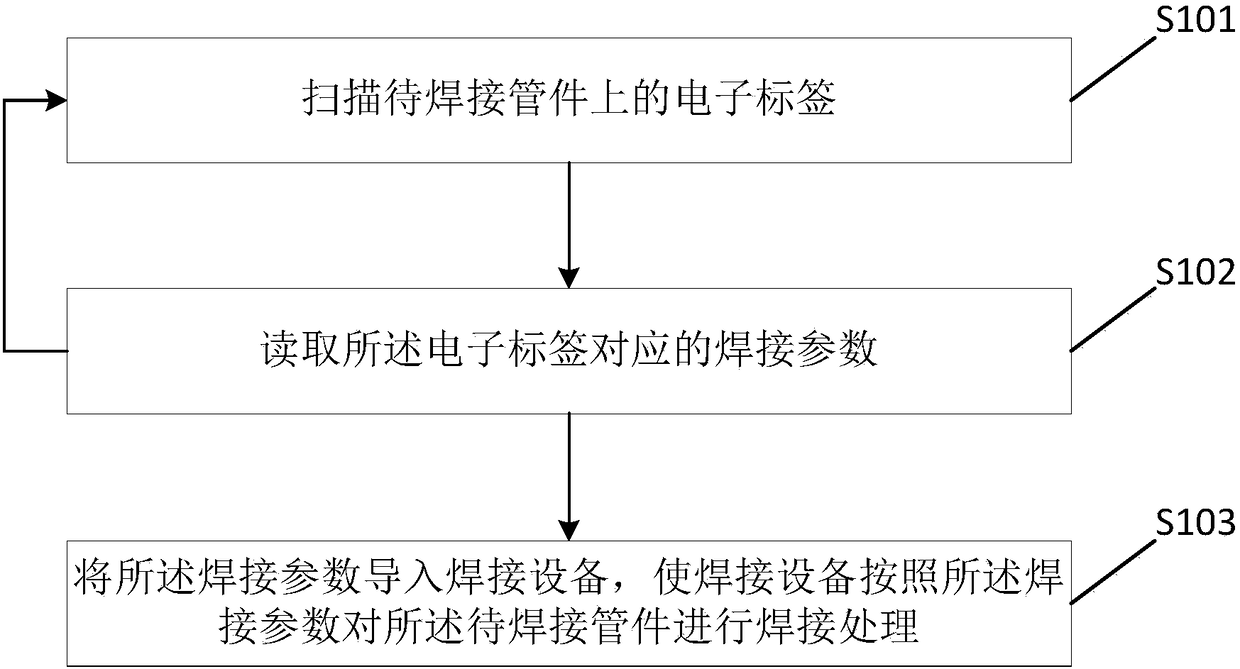

[0055] See figure 1 , Is a flowchart of the first embodiment of the intelligent welding method for nuclear power pipe fittings provided by the present invention, and the method includes:

[0056] Step S101: Scan the electronic label on the pipe to be welded. Wherein, the electronic tag is provided with information of the pipe fitting to be welded, such as pipe fitting type, pipe outer diameter, SDR, wall thickness, etc. The electronic tag may be an information identification such as RFID or a two-dimensional code.

[0057] Step S102: Read welding parameters corresponding to the electronic tag. Among them, the welding parameters may include preheating temperature, pipe planing pressure, leveling pressure, heating pressure, heating time, conversion time, welding pressure, pressure holding cooling time, etc.

[0058] Step S103: Import the welding parameters into the welding equipment, so that the welding equipment performs welding processing on the pipe fitting to be welded according ...

no. 2 example

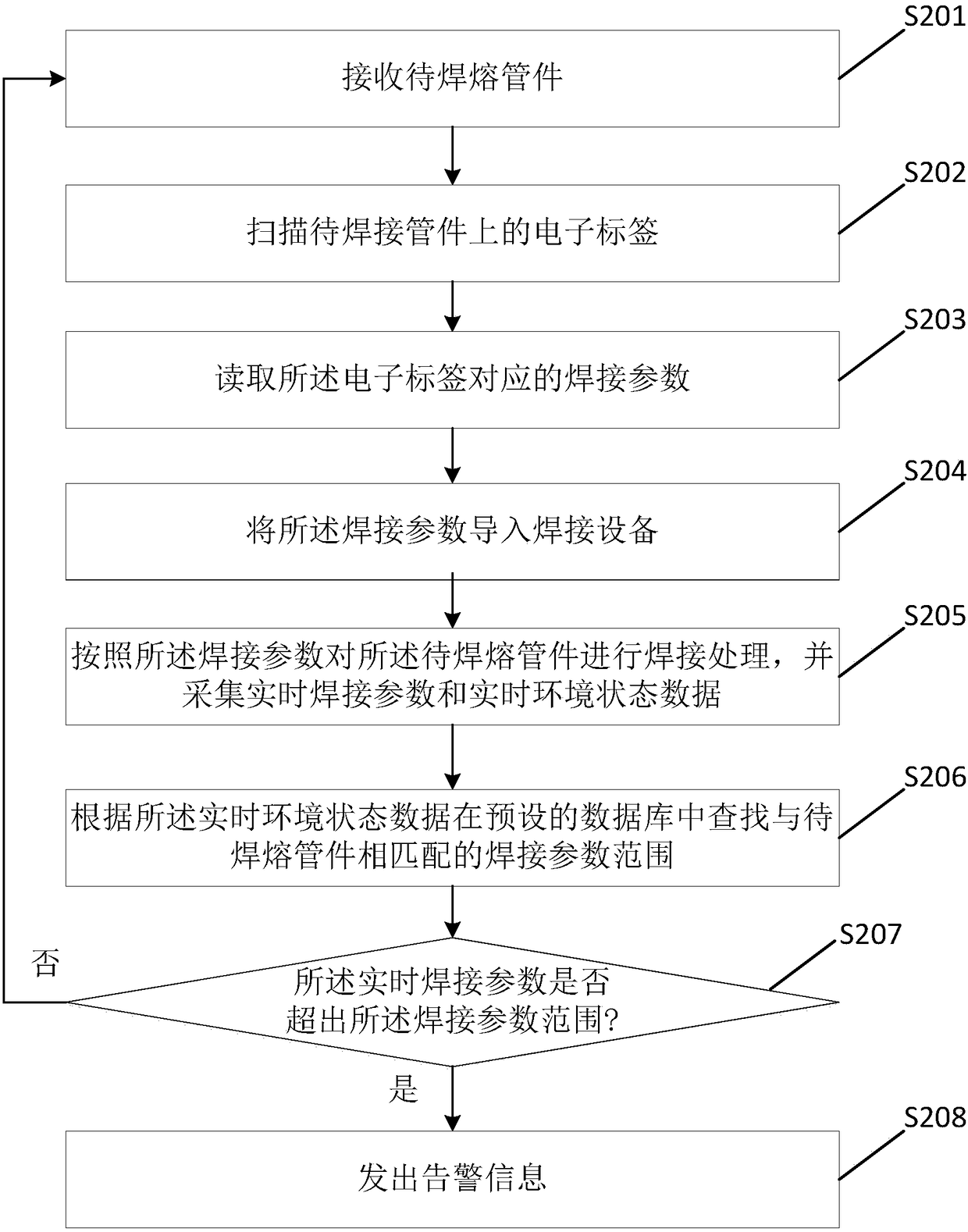

[0060] See figure 2 , Is a flowchart of the second embodiment of the automatic welding method for nuclear-grade PE pipe fittings provided by the present invention. The method includes:

[0061] Step S201: Receive the pipe fitting to be welded.

[0062] Step S202: Scan the electronic label on the pipe to be welded. Wherein, the electronic tag is provided with information of the pipe fitting to be welded, such as pipe fitting type, pipe outer diameter, SDR, wall thickness, etc. The electronic tag may be an information identification such as RFID or a two-dimensional code.

[0063] Step S203: Read the welding parameters corresponding to the electronic tag. Welding parameters can include preheating temperature, planing pressure, leveling pressure, heating pressure, heating time, conversion time, welding pressure, pressure holding cooling time, etc.

[0064] Step S204: Import the welding parameters into the welding equipment.

[0065] Step S205: Perform welding processing on the pipe fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com