Automatic welding method for double-station distribution box robot welding workstation

A robot welding and automatic welding technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of low welding efficiency, and achieve the effects of improving welding quality and work efficiency, saving manpower, and stable welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

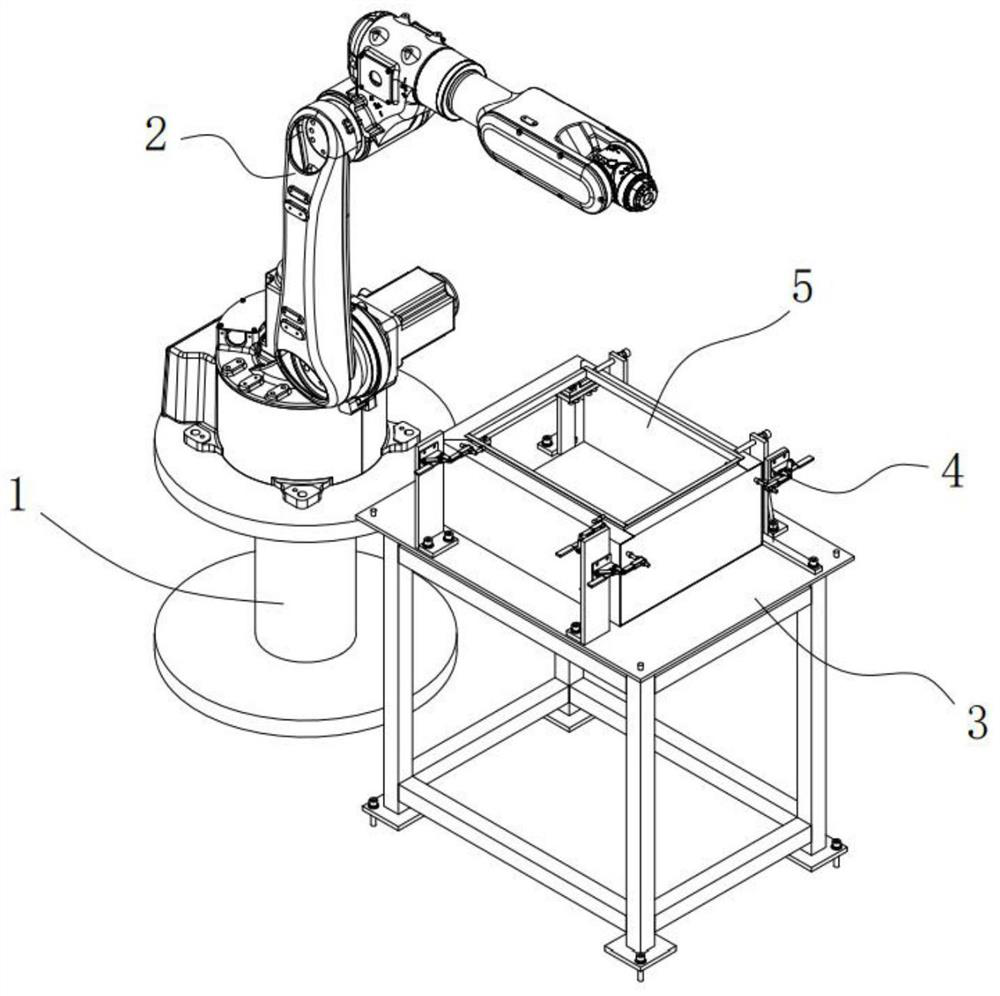

[0030] see figure 1 As shown, the present invention discloses a robot welding workstation for a double-station distribution box, which includes a positioner 1, a welding robot 2 installed on the positioner 1, and a welding gun installed at the end of the welding robot 2 mechanical arm (Fig. The end is not drawn above), the workbench 3 respectively positioned on the two stations (only one of the stations has been shown on the figure, and the other station is on the side, forming a right angle orientation between the two stations), the workbench 3 is provided with a fixture 4 for fixing the workpiece to be welded. The welding robot 2 is driven by the positioner 1 and can rotate between the two stations. When the workpiece on one station is welded, it can be transferred to another station. At this time, the operator can use the gap to disassemble the welded distribution box from the fixture of the workbench and install a new workpiece to be welded to improve welding efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com