Alloy aluminum paste for back surface of PERC solar cell

A solar cell and alloy aluminum technology, applied in the field of alloy aluminum paste, can solve the problems of low gap filling rate and irregularity, and achieve the effect of complete and uniform BSF layer, reduced aluminum beads, and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

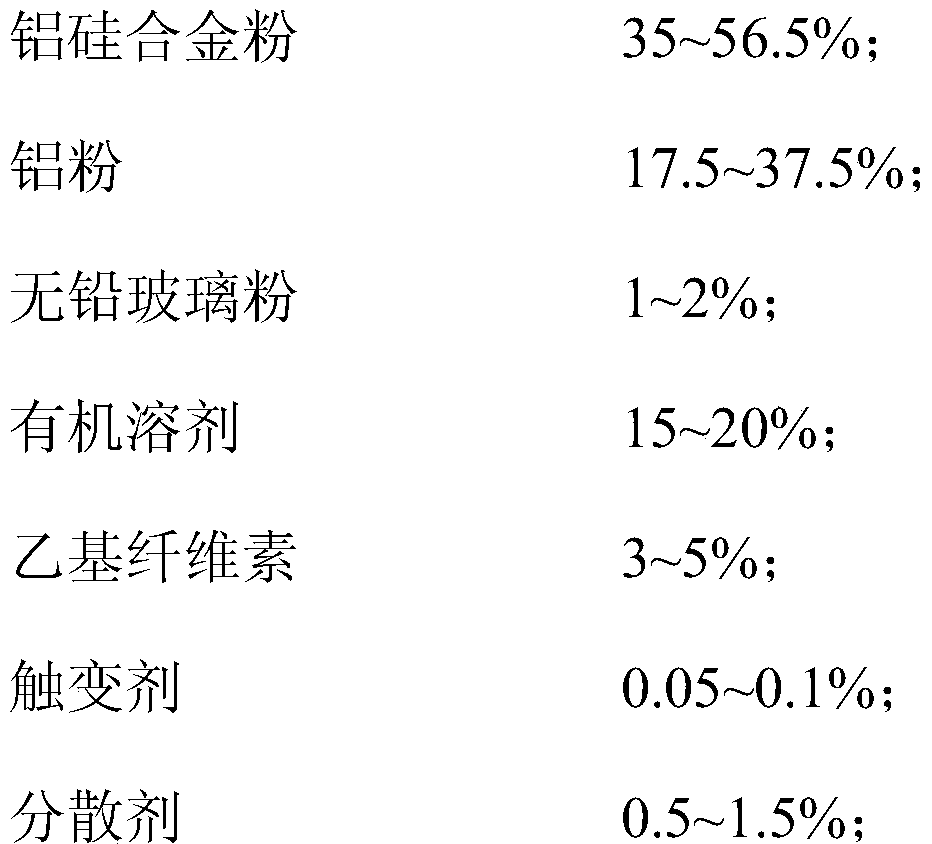

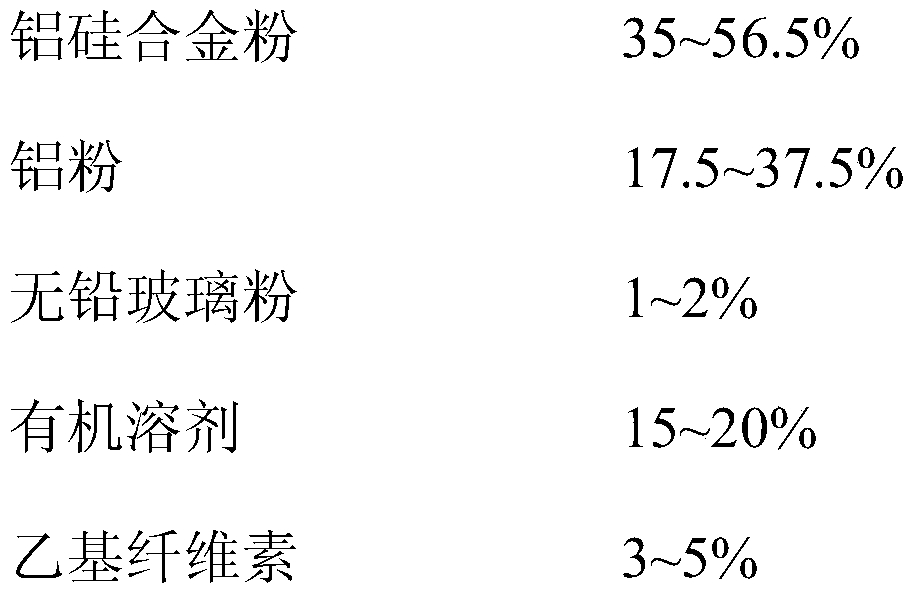

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of lead-free glass powder

[0032] The preparation of glass powder A: take the weight of glass powder A as 100%, prepare 20% ZnO, 20% B 2 o 3 , 35% Sb 2 o 3 , 5% BaCl 2 , 10%Na 2 CO 3 and 10% Rb 2 o 2 , this example uses BaCl 2Metal compounds of other halogen group elements are also applicable by adjusting the addition ratio, and then utilize known mixers such as a disperser or a three-roller to mix each material evenly, then carry out drying treatment for 3.5h, and then transfer the dried treatment raw materials to In the crucible, put the crucible containing the raw materials into the heating chamber, first raise the temperature to 950 ° C, and then keep it warm for 1.5 hours, then pass the smelted material liquid through cooling rollers to obtain glass frit, and then crush and sieve the glass frit The median particle size D 50 The glass frit A is 1.36 μm and the softening temperature is 544.7°C.

[0033] Preparation of glass frit B: take the...

Embodiment 2

[0039] 1. Preparation of lead-free glass powder

[0040] The preparation of glass powder A: take the weight of glass powder A as 100%, prepare 40% ZnO, 5% B 2 o 3 , 30% Sb 2 o 3 , 5% SrCl, 10% Cs 2 CO 3 And 10% BaO, what this embodiment adopts is that the metal compound of SrCl and other halogen group elements is also applicable by adjusting the addition ratio, then utilize known mixers such as disperser or three-roller to mix each material evenly, then carry out Drying treatment for 3 hours, then transfer the dried raw materials into the crucible, then place the crucible containing the raw materials in the heating chamber, first raise the temperature to 850 °C, then keep it warm for 2 hours, and then pass the smelted material liquid through cooling rollers to obtain Glass frit, then the glass frit is crushed and sieved to obtain the median particle size D 50 The glass frit A is 1.89 μm and the softening temperature is 570°C.

[0041] Preparation of glass frit B: take t...

Embodiment 3

[0048] 1. Preparation of lead-free glass powder

[0049] The preparation of glass powder A: take the weight of glass powder A as 100%, prepare 10% ZnO, 30% B 2 o 3 , 30% Sb 2 o 3 , 10% CaCl 2 , 10%K 2 CO 3 and 10% Cs 2 O, what this embodiment adopts is CaCl 2 Metal compounds of other halogen elements are also applicable by adjusting the addition ratio, and then use a known mixer such as a disperser or a three-roller to mix the various materials evenly, then dry them for 4 hours, and then transfer the dried raw materials to the crucible In the heating chamber, put the crucible containing the raw materials into the heating chamber and raise the temperature to 1050°C, then keep it warm for 2 hours, then pass the smelted material liquid through cooling rollers to obtain glass frit, and then crush and sieve the glass frit to obtain Median particle size D 50 The glass frit A is 2.17μm and the softening temperature is 530.6°C.

[0050] Preparation of glass frit B: take the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com