Trivalent bismuth ion doped yttrium-lutetium-gallium-aluminum garnet ultraviolet long-afterglow luminescent material and preparation method thereof

A luminescent material, bismuth ion technology, applied in the field of material science, achieves the effect of simple operation method, strong practicability, and good ultraviolet long afterglow luminescence ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] As introduced in the background art, the emission region of the ultraviolet long-lasting luminescent materials in the prior art is mainly concentrated in the long-wave ultraviolet region (340-400nm). Therefore, the present invention proposes a trivalent bismuth ion (Bi 3+ ) doped yttrium lutetium gallium aluminum garnet ultraviolet long afterglow luminescent material preparation method, comprising the following steps:

[0035] Weigh lutetium oxide and / or yttrium oxide, gallium oxide, aluminum oxide and bismuth oxide raw materials according to mole percentage, and mix the raw materials and flux B 2 o 3 Grinding and mixing in a mortar, pre-calcining the prepared powder at a low temperature, pressing the pre-calcined powder into tablets, and then sintering at a high temperature to obtain an ultraviolet long-lasting luminescent material;

[0036] preferred, B 2 o 3 The added amount is 0.1-1wt% of the total mass of lutetium oxide, yttrium oxide, gallium oxide, aluminum o...

Embodiment 1

[0044] According to the following ingredients: UV long afterglow luminescent material Y 3 Ga 5 o 12 : Bi 3+ , with Y 3 Ga 5 o 12 as the matrix, doped with ions Bi 3 + is the active ion, where Bi 3+ The doping amount is 2mol%. Accurately weigh yttrium oxide (Y 2 o 3 )0.6061g, gallium oxide (Ga 2 o 3 ) 0.8415g, bismuth oxide (Bi 2 o 3 )0.0084g and boron oxide (B 2 o 3 ) 0.0073g. Put the above raw materials in an agate mortar and grind for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire them at 900°C for 2 hours. After the calcined powder is reground, use a powder tablet press to press about 1 g of the powder into a disc with a diameter of about 15 mm and a thickness of about 1 mm. Finally, the shaped disc was sintered at 1600°C for 4 hours to obtain Y 3 Ga 5 o 12 : Bi 3+ UV long afterglow luminescent material.

[0045] The sample prepared in embodiment 1 is detected:

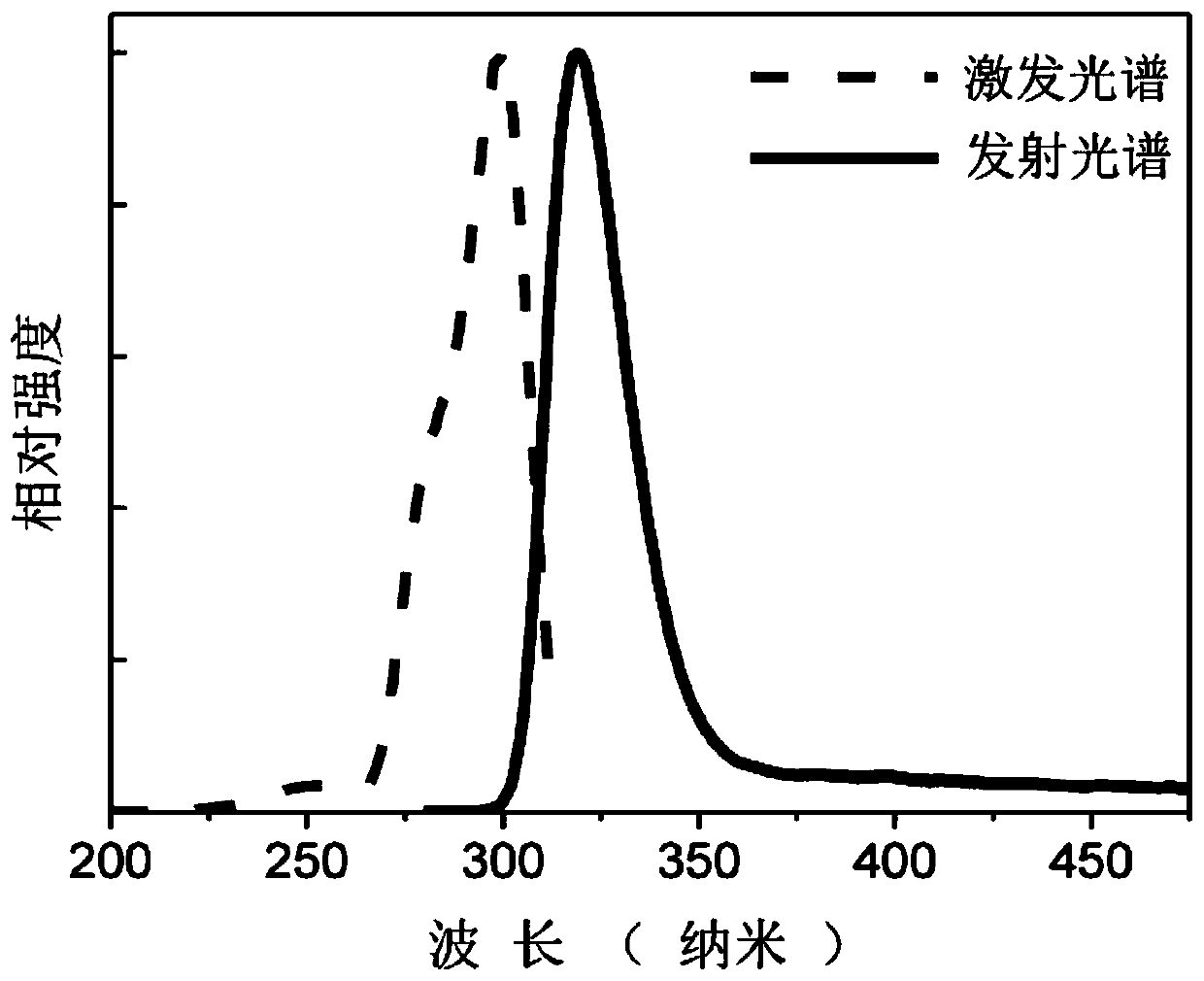

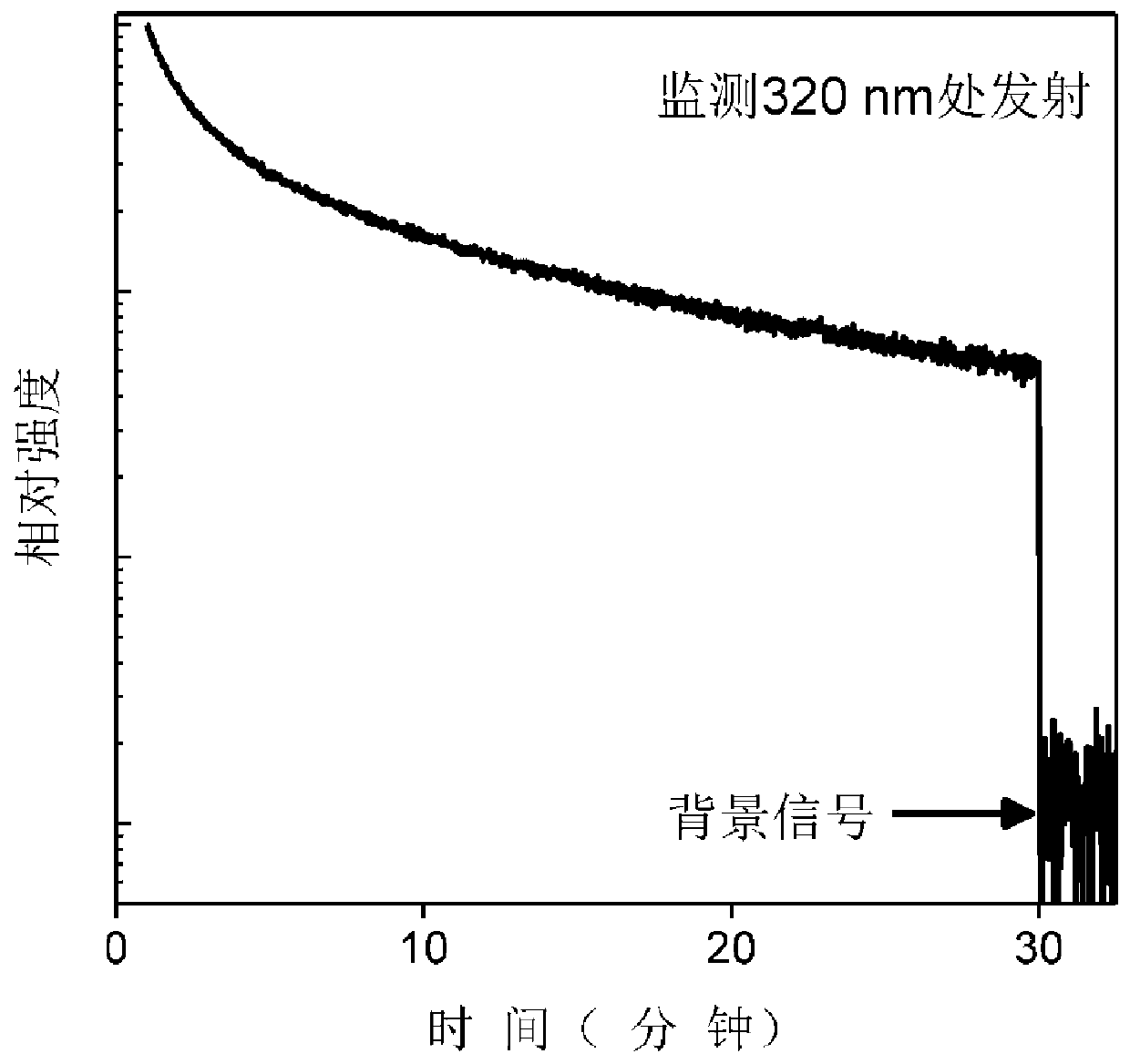

[0046] For the excitation and e...

Embodiment 2

[0051] According to the following ingredients: UV long afterglow luminescent material Y 3 Al 2 Ga 3 o 12 : Bi 3+ , with Y 3 Al 2 Ga 3 o 12 as the matrix, doped with ions Bi 3+ is the active ion, where Bi 3+ The doping amount is 2mol%; Accurately weigh yttrium oxide (Y 2 o 3 )0.6061g, gallium oxide (Ga 2 o 3 ) 0.5049g, alumina (Al 2 o 3 ) 0.1836g, bismuth oxide (Bi 2 o 3 )0.0084g and boron oxide (B 2 o 3 ) 0.013g. Put the above raw materials in an agate mortar and grind for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire them at 1000°C for 2 hours. After the calcined powder is reground, use a powder tablet press to press about 1 g of the powder into a disc with a diameter of about 15 mm and a thickness of about 1 mm. Finally, the shaped disc was sintered at 1500°C for 6 hours to obtain Y 3 Al 2 Ga 3 o 12 : Bi 3+ UV long afterglow luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence peak | aaaaa | aaaaa |

| Luminescence peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com