Photocurable liquid silicone rubber catalyst with high dispersibility, and preparation method thereof

A liquid silicone rubber, high dispersion technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of large consumption and poor catalyst dispersion , to achieve the effect of reducing consumption, good dispersion, convenient and effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

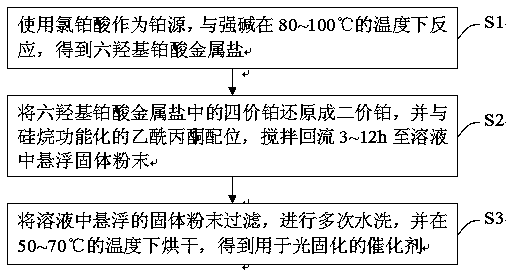

[0025] Such as figure 1 Shown, the preparation method of this catalyst comprises:

[0026] S1 uses chloroplatinic acid as a platinum source and reacts with a strong base at a temperature of 80-100°C (Celsius) to obtain a hexahydroxyplatinic acid metal salt; the strong base is NaOH, KOH or LiOH.

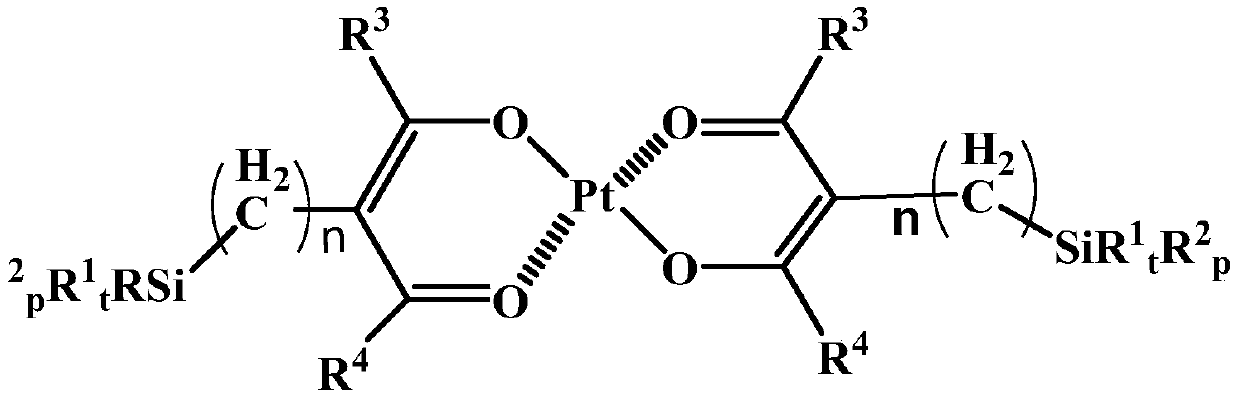

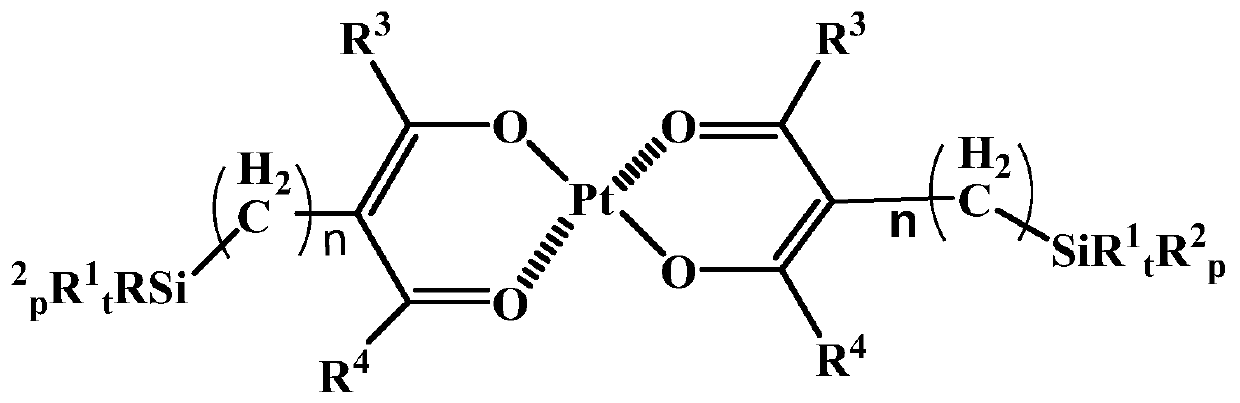

[0027] S2: Reducing tetravalent platinum in hexahydroxyplatinic acid metal salt to divalent platinum, and coordinating with silane-functionalized acetylacetone, stirring and refluxing for 3-12 hours (hours) to suspend solid powder in the solution. Specifically, the silane functionalization of acetylacetone is achieved by combining with alkylsilane after deprotonation of sodium cyanide or methyllithium, and the acetylacetone ligand for silane functionalization is (3-methyldimethoxysilyl) acetylacetone , (3-methyldimethoxysilyl) 1-phenyl-1,3-butanedione, (3-methyldimethoxysilyl) 1,3-diphenyl-1,3- Any one of propylenedione, (3-methyldimethoxysilyl)1,1,1,5,5,5-hexafluoro-2,4-pentanedion...

Embodiment 1

[0029] Example 1: Synthesis of two [(3-methyldimethoxysilyl) acetylacetonate] platinum (II)

[0030] Take 6.0g (gram) H 2 PtCl 6 ·6H 2 O was put into a 100mL (milliliter) single-necked bottle, and 40mL of water was added to dissolve it into a reddish-brown color. After that, 15.6g of NaOH was added, and heated to 110°C for 3h under reflux. In the process of reflux, the solution starts to be yellow, and after half an hour of reaction, the color becomes lighter and gradually becomes transparent and clear; after 1 hour of reaction, yellow suspended powder appears; after 3 hours, the reaction is stopped, and a large amount of yellow powder is precipitated after being cooled in the refrigerator overnight. Sodium hydroxyplatinate (Na 2 Pt(OH) 6). Afterwards, the supernatant was poured out, methanol was added to wash the yellow powder three times, filtered with suction, dried and weighed to obtain 3.8 g of the yellow powder. In this process, the yield reached 95.47%.

[0031] ...

Embodiment 2

[0033] Example 2: Synthesis of two [(3-methyldimethoxysilyl) 1-phenyl-1,3-butanedione] platinum (II)

[0034] Weigh 2.5g of prepared Na 2 Pt(OH) 6 (See Example 1) Place in a three-necked flask, add 20mL of water and shake well, then add 4.86g of (3-methyldimethoxysilyl) 1-phenyl-1,3-butanedione and 200uL of Concentrated sulfuric acid was heated to reflux at 85°C to obtain a milky white turbid solution (mixed solution); after that, dilute 400uL HCOOH in 500mL water, and drop the diluted HCOOH into the mixed solution through a constant pressure dropping funnel. Reaction 3h, in this process, solution becomes black or dark green when reaction 1h, upper layer floats a small amount of yellow powder; Then react overnight, stop reaction and filter to obtain light green powder, i.e. bis[(3-methyldimethoxy silyl) 1-phenyl-1,3-butanedione] platinum (II).

[0035] After weighing, the light green powder was 5.32g, and the yield was 75.20%. ICP analysis of this light green powder reveal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com