Metal plate single surface and graphite composite bipolar plate and preparation method

A metal plate and unipolar plate technology, which is applied in the direction of final product manufacturing, fuel cell parts, sustainable manufacturing/processing, etc., can solve the problems of high price, low mechanical strength, high processing cost, etc., and achieve improved corrosion resistance Sexuality, the effect of reducing the cost of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

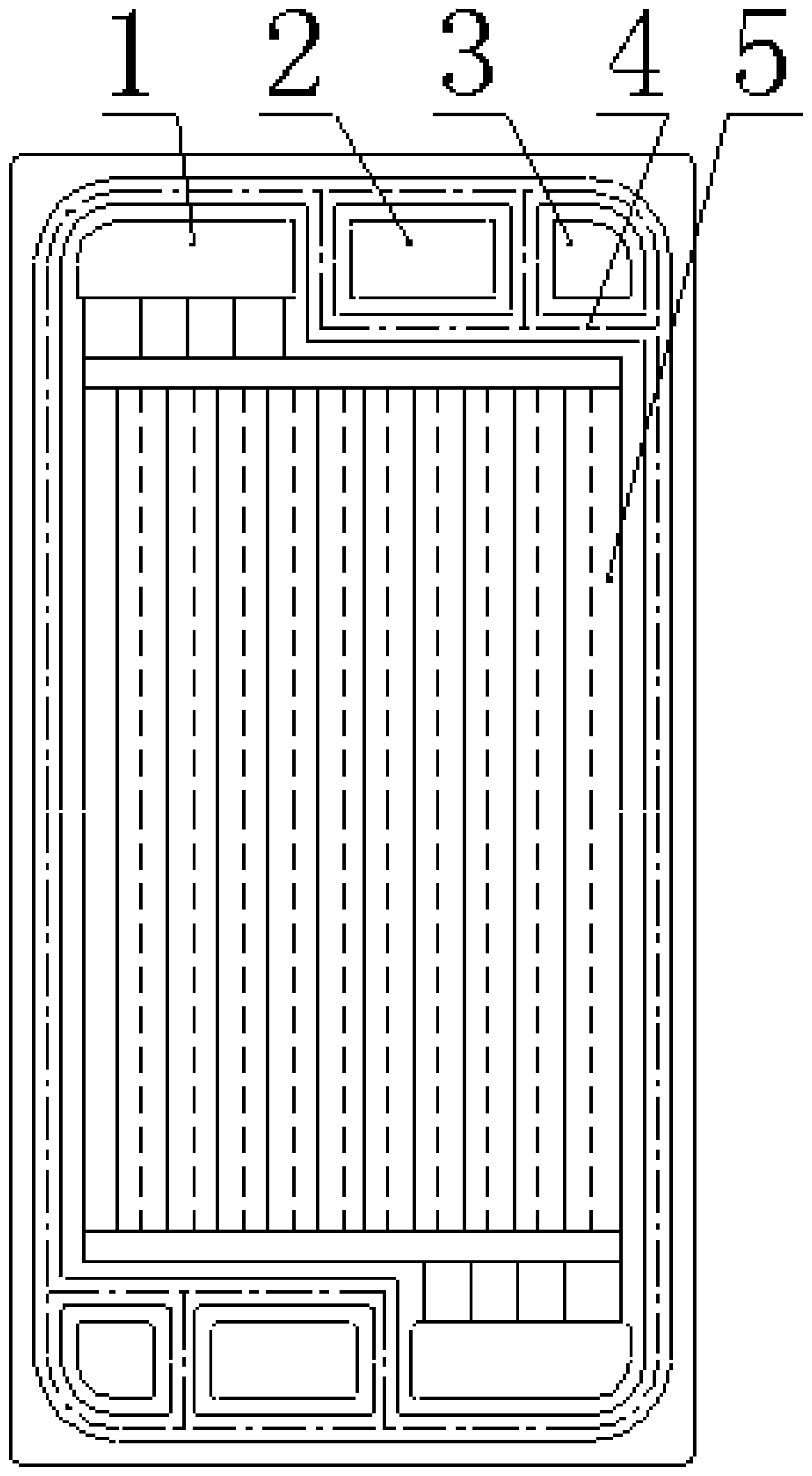

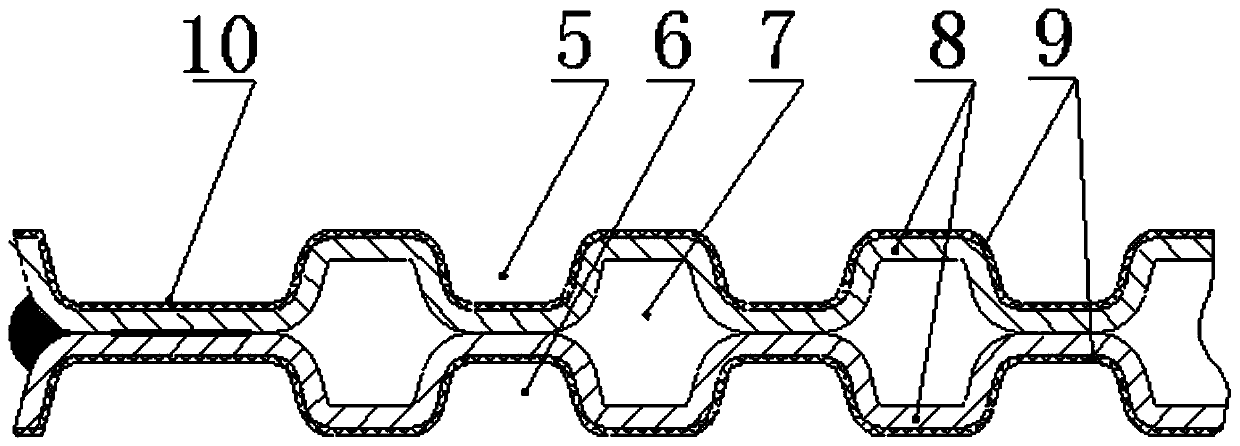

[0027] A bipolar plate composited with graphite on one side of a metal plate, including a hydrogen unipolar plate and an oxygen unipolar plate, the hydrogen unipolar plate and the oxygen unipolar plate are respectively provided with a hydrogen flow field 6, an air flow field 5, an air channel 1, Coolant channel 2, hydrogen channel 3 and sealant duct 4, hydrogen flow field 6 and air flow field 5 are corrugated plate flow fields, hydrogen unipolar plates and oxygen unipolar plates are composite unipolar plates, composite unipolar The plate is made of composite metal plate 8 and graphite. The metal plate 8 is any one of stainless steel plate, aluminum plate or copper plate. The thickness of the metal plate 8 is 0.05mm-0.1mm. Conductive layer, the conductive layer is silver, gold or platinum plating or carbon, carbide or nitride sputtering layer, the thickness of the conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com