Device and method for width monitoring and regional self-positioning of tensile fracture of concrete

A crack width, concrete technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure test material strength, etc., can solve the problems of high cost, high content of conductive materials, inability to judge concrete cracks and real-time monitoring, etc. , to achieve the effect of eliminating tedious work, avoiding difficulty in dispersing, and flexibly arranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

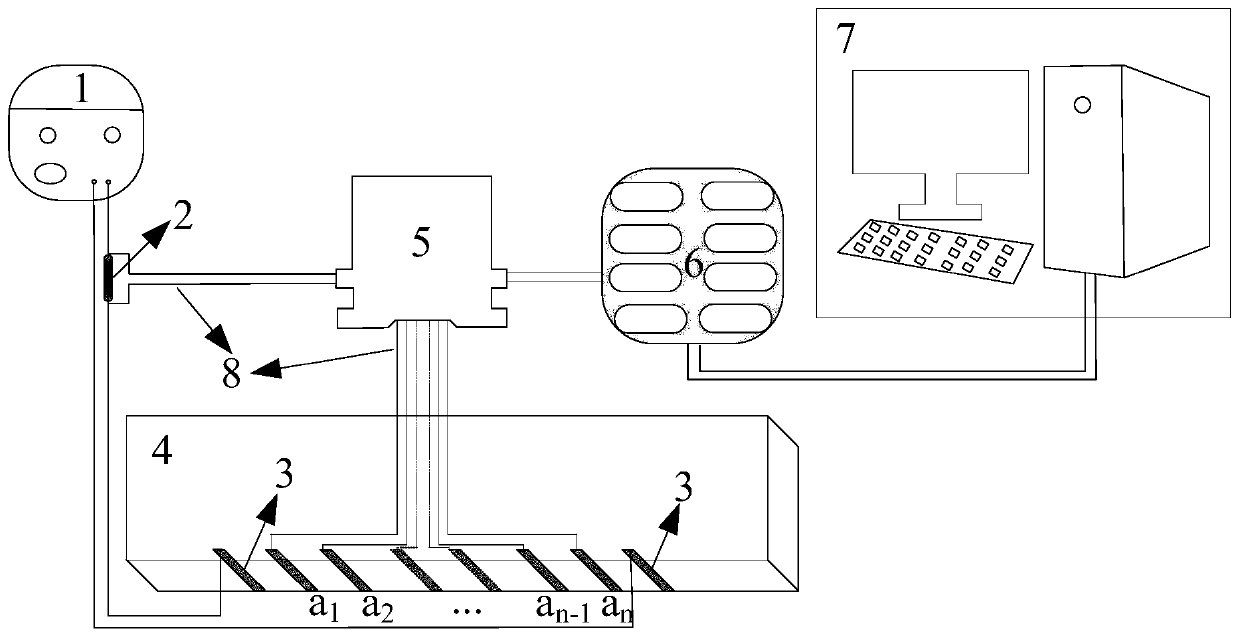

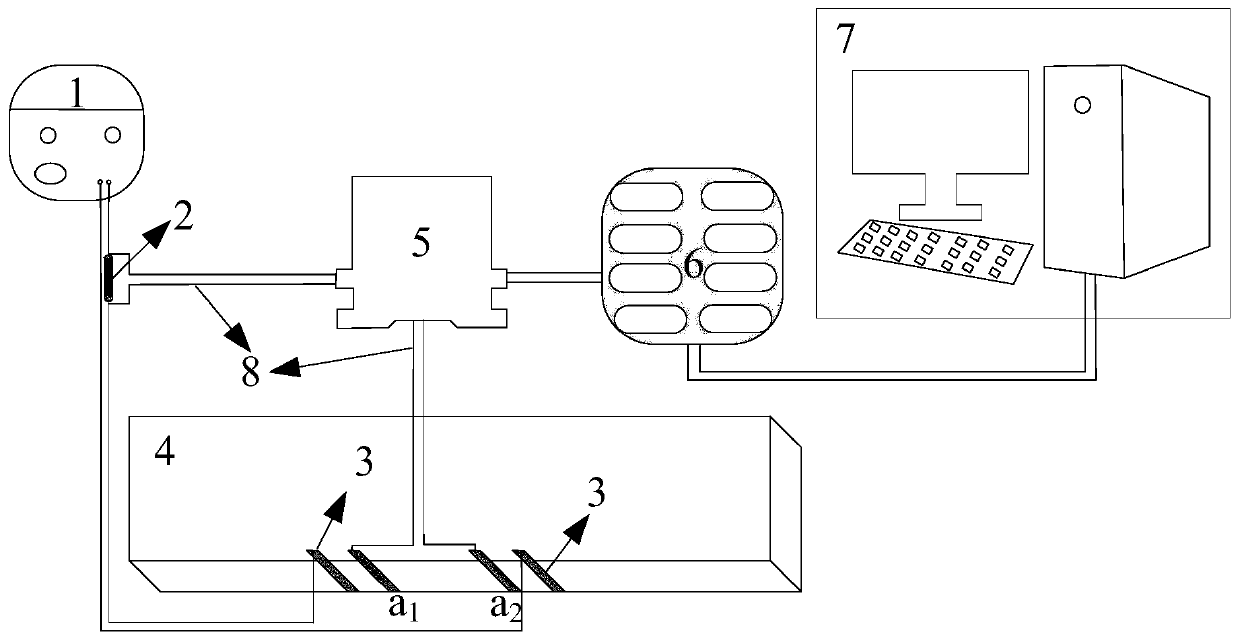

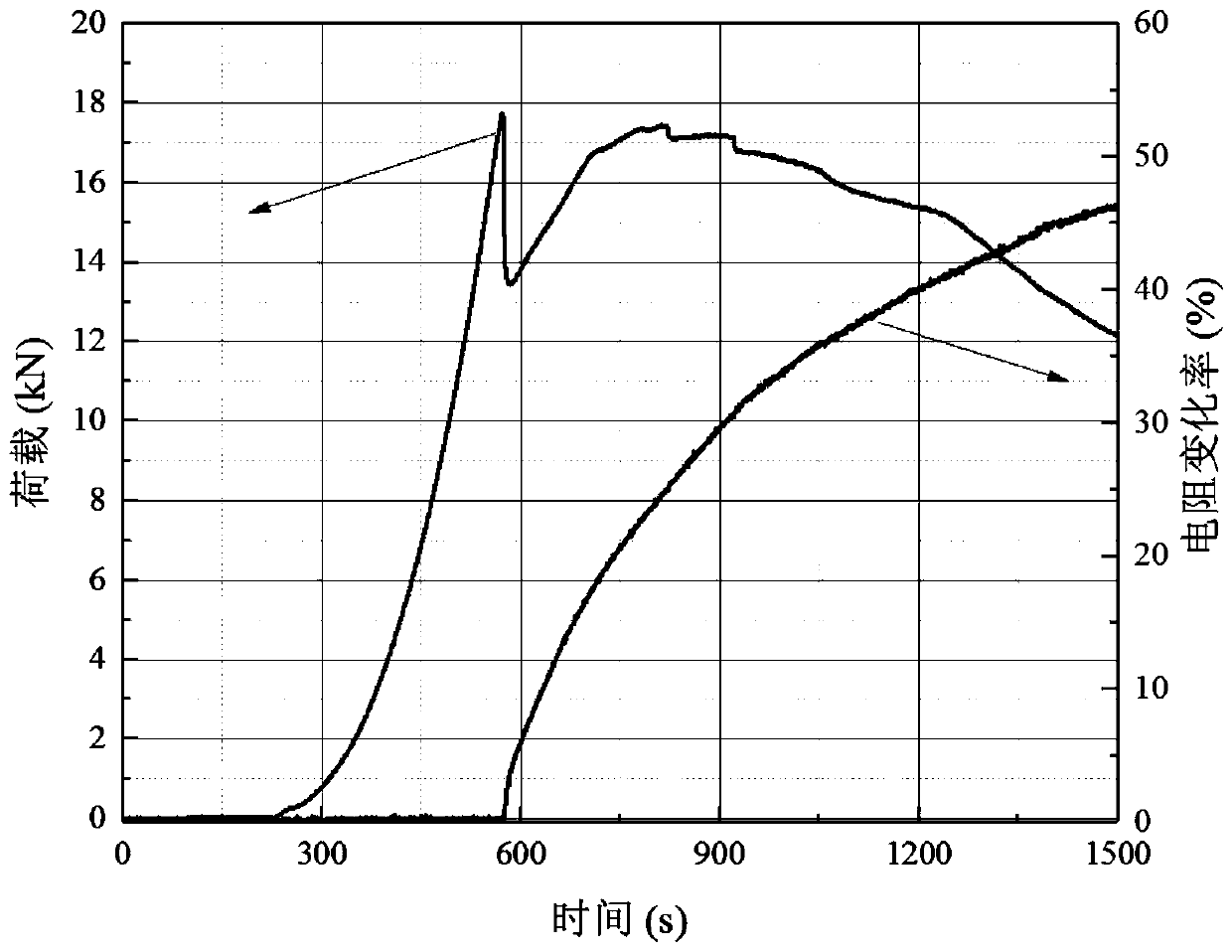

[0033] When the number of internal electrodes in the device of the present invention is 2 (n=2), the self-monitoring of the crack width of the concrete tension side can be realized. Refer to attached figure 2 , described in this embodiment is a self-monitoring technology for the width of a concrete crack, and the specific implementation method is as follows:

[0034] The first step is to connect the circuit, and each component: DC stabilized power supply 1, fixed value resistor 2 (resistance value = 5kΩ), external conductive electrode 3 (embedded type, brass mesh 12 mesh 0.38mm wire diameter, width 15mm ), the distance between the outer electrode and the inner electrode is 30mm, and the inner conductive electrode a 1 、a 2 (embedded type, brass mesh 12 mesh 0.38mm wire diameter, width 15mm, spacing 100mm), steel fiber reinforced concrete members 4 (40kg / m 3 steel fiber), voltage conversion module 5, data acquisition system 6, computer 7, according to the instructions attach...

specific Embodiment approach

[0040] When it is necessary to judge the cracking area on the tension side of the concrete member 4 or monitor the cracking area, the device involved in the present invention can achieve the goal by adding internal electrodes. For example, when the number of internal electrodes is 3 (n=3), the crack location in the two crack areas of concrete can be realized, refer to the attached Figure 5 , described in this embodiment is a concrete crack area positioning technology, the specific implementation is as follows:

[0041] In the first step, arrange two external electrodes 3 (internal embedded type, brass mesh 12 mesh 0.38mm wire diameter, width 15mm) in the tension area of fiber concrete member 4, and arrange three internal electrodes a 1 、a 2 、a 3 (Internal embedded type, brass mesh 12 mesh, wire diameter 0.38mm, width 15mm), the distance between adjacent internal electrodes is 42.5mm, and the distance between external electrodes and adjacent internal electrodes is 30mm. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com