Composite rock slice, color-sand-free stone-like paint and preparation method thereof

A technology of composite rock flakes and imitation stone paint, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as bleeding of rock flakes, stability of whole rock flake coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

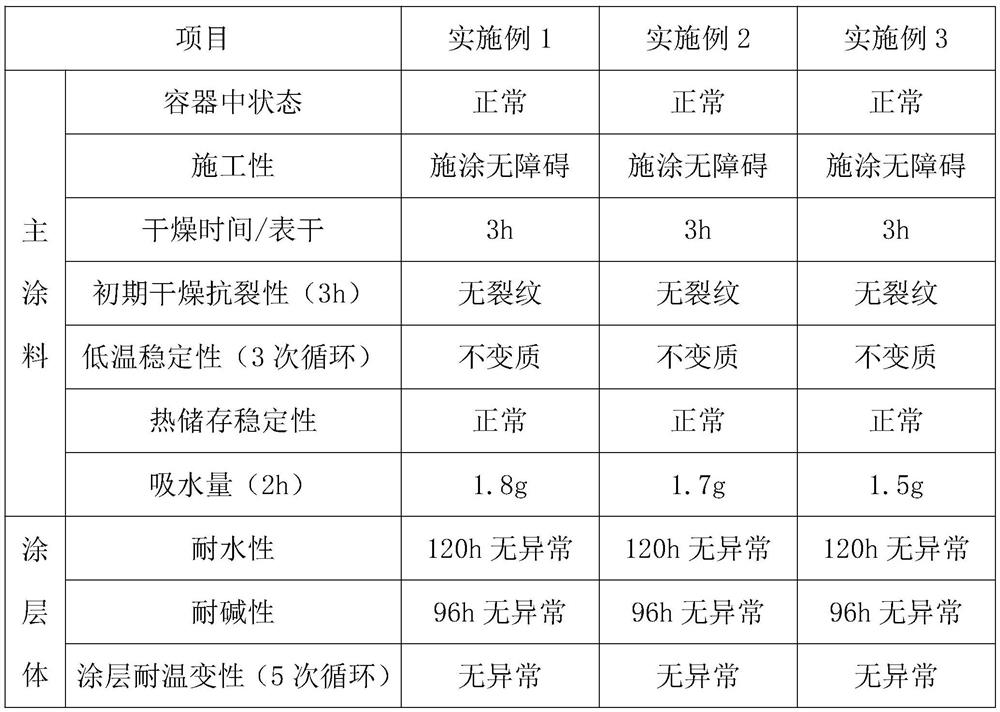

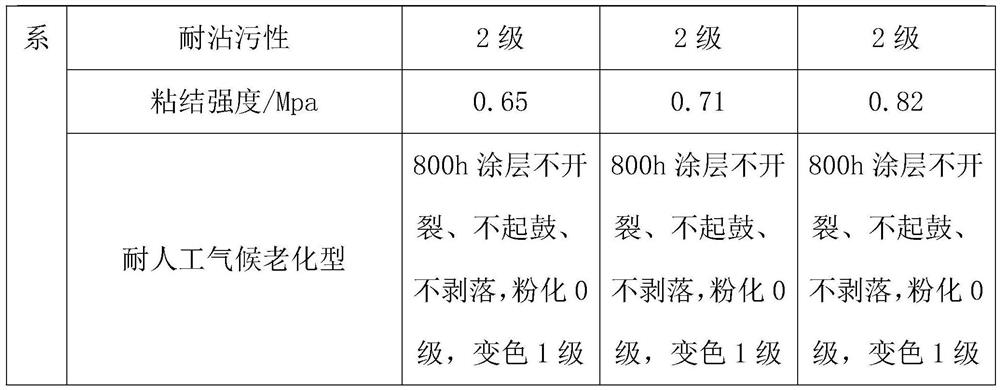

Examples

Embodiment 1

[0062] A composite rock slice is prepared from the following components in mass fraction ratio:

[0063] 20 parts of polyester diol, 20 parts of diisocyanate, 10 parts of chain extender, 0.1 part of antioxidant, 0.3 part of lubricant, 0.1 part of light stabilizer, 0.05 part of catalyst, 25 parts of inorganic filler, 0.05 part of pigment and even Joint agent 0.3 part.

[0064] The polyester diol is polyethylene adipate diol with a molecular weight of 1500.

[0065] Described diisocyanate is isophorone diisocyanate.

[0066] The chain extender is a mixture of 1,4-butanediol and 1,6-hexanediol in a mass ratio of 1:1; the antioxidant is hindered phenol antioxidant; the lubricant is sub Ethyl bis-stearamide; the catalyst is an organic bismuth compound; the inorganic filler is a mixture of kaolin, mica powder, and talcum powder in a ratio of 1:1:1; the pigment is a 400-800 purpose toner , the silane coupling agent is KH550.

[0067] A method for preparing a composite rock slice,...

Embodiment 2

[0094] A composite rock slice is prepared from the following components in mass fraction ratio:

[0095] 30 parts of polyester diol, 15 parts of diisocyanate, 2 parts of chain extender, 0.5 part of antioxidant, 0.01 part of lubricant, 1.1 part of light stabilizer, 0.01 part of catalyst, 20 parts of inorganic filler, 0.01 part of pigment and even Joint agent 0.5 part.

[0096] The polyester diol is polyethylene adipate diol with molecular weight between 2000.

[0097] Described diisocyanate is hexamethylene diisocyanate.

[0098]The chain extender is a mixture of 1,4-butanediol and 1,6-hexanediol in a mass ratio of 1.5:1; the antioxidant is hindered phenol antioxidant (AO-60); the The lubricant is ethylene bisstearamide; the catalyst is an organic bismuth compound; the inorganic filler is a mixture of barium sulfate, calcium carbonate, and titanium dioxide in a ratio of 1:2:3; the pigment For 400-800 mesh toner, the coupling agent is KH560.

[0099] A method for preparing a...

Embodiment 3

[0126] A composite rock slice is prepared from the following components in mass fraction ratio:

[0127] 40 parts of polyester diol, 10 parts of diisocyanate, 5 parts of chain extender, 0.3 part of antioxidant, 0.17 part of lubricant, 2 parts of light stabilizer, 0.1 part of catalyst, 30 parts of inorganic filler, 0.1 part of pigment and even Joint agent 0.6 part.

[0128] The polyester diol is polyethylene adipate diol with molecular weight between 2500.

[0129] Described diisocyanate is isophorone diisocyanate.

[0130] The chain extender is a mixture of 1,4-butanediol and 1,6-hexanediol in a mass ratio of 2:1; the antioxidant is hindered phenol antioxidant; the lubricant is sub Ethylbisstearamide; Described catalyst is organic bismuth compound; Described inorganic filler is the mixture that kaolin, talcum powder, barium sulfate, titanium dioxide mix according to 1:2:1:4 ratio; Described pigment is 400-800 mesh toner, the coupling agent is a 1:1 mixture of KH550 and KH56...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com