Waterborne plastic paint and preparing method and use method thereof

A plastic coating, water-based technology, applied in anti-corrosion coatings, fire-resistant coatings, polyether coatings, etc., can solve the problems of large environmental pollution, high VOC content, poor solvent resistance on the sprayed surface, and achieve good surface adaptability and leveling. Excellent, good adhesion results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

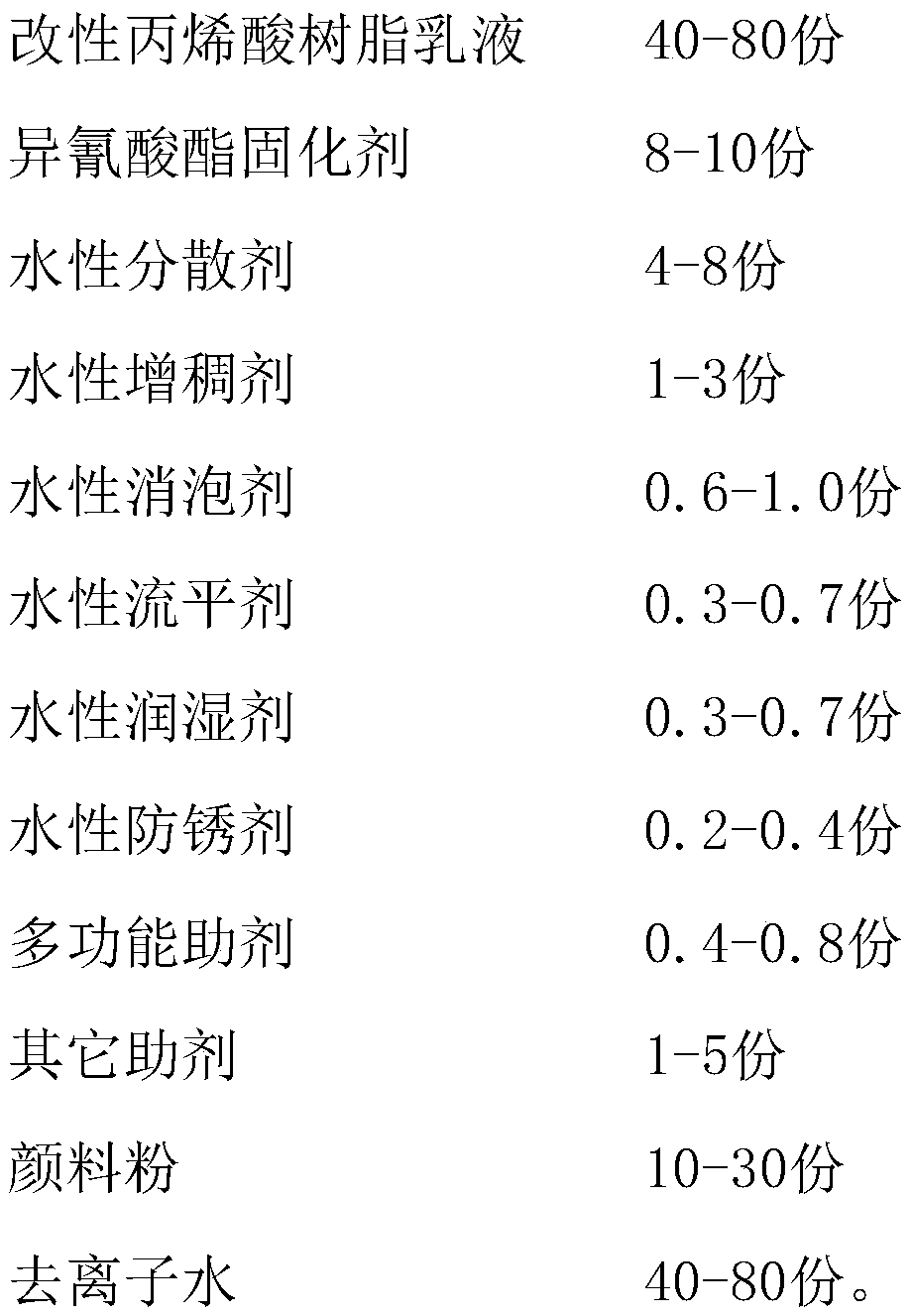

[0064] A kind of water-based plastic coating, described water-based plastic coating comprises the raw material of following weight portion:

[0065]

[0066] The modified acrylic resin emulsion is a silicone modified acrylic resin emulsion with a solid content of 47% and a viscosity of 600mpa.s; the aqueous dispersant is made of polyacrylamide, ethylene bisstearamide and fatty acid polyethylene A mixture of glycol esters in a weight ratio of 0.4:1:1.4.

[0067] The water-based thickener is a mixture of sodium carboxymethylcellulose, polyurethane thickener and polyacrylic acid salt alkali swelling emulsion in a weight ratio of 1:0.5:2; the water-based defoamer is made of polyoxypropylene A mixture of oxyethylene glyceryl ether, polydimethylsiloxane and simethicone in a weight ratio of 4:2:1.

[0068] The water-based leveling agent is a mixture composed of polyether modified polydimethylsiloxane, polyether polyester modified organosiloxane and alkyl modified organosiloxane i...

Embodiment 2

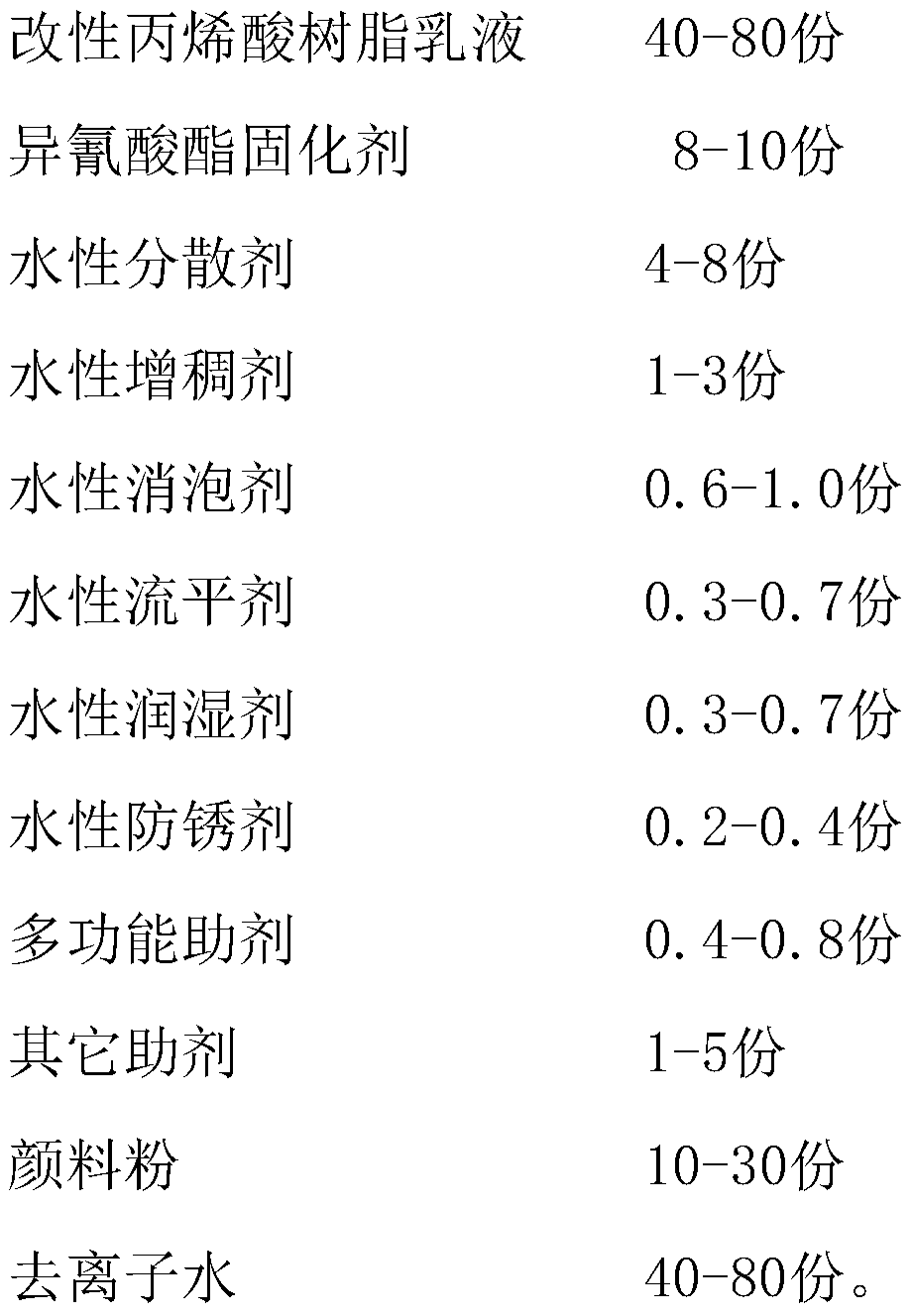

[0095]A kind of water-based plastic coating, described water-based plastic coating comprises the raw material of following weight portion:

[0096]

[0097] The modified acrylic resin emulsion is a silicone modified acrylic resin emulsion with a solid content of 47.5% and a viscosity of 650mpa.s; A mixture of glycol esters in a weight ratio of 0.5:1:1.6.

[0098] The water-based thickener is a mixture of sodium carboxymethylcellulose, polyurethane thickener and polyacrylic acid salt alkali swelling emulsion in a weight ratio of 1:0.8:2.5; the water-based defoamer is made of polyoxypropylene A mixture of oxyethylene glyceryl ether, polydimethylsiloxane and simethicone in a weight ratio of 4.5:2.5:1.

[0099] The water-based leveling agent is a mixture of polyether modified polydimethylsiloxane, polyether polyester modified organosiloxane and alkyl modified organosiloxane in a weight ratio of 1.6:2.5:1 ; The water-based wetting agent is a mixture of sodium dodecyl sulfonate...

Embodiment 3

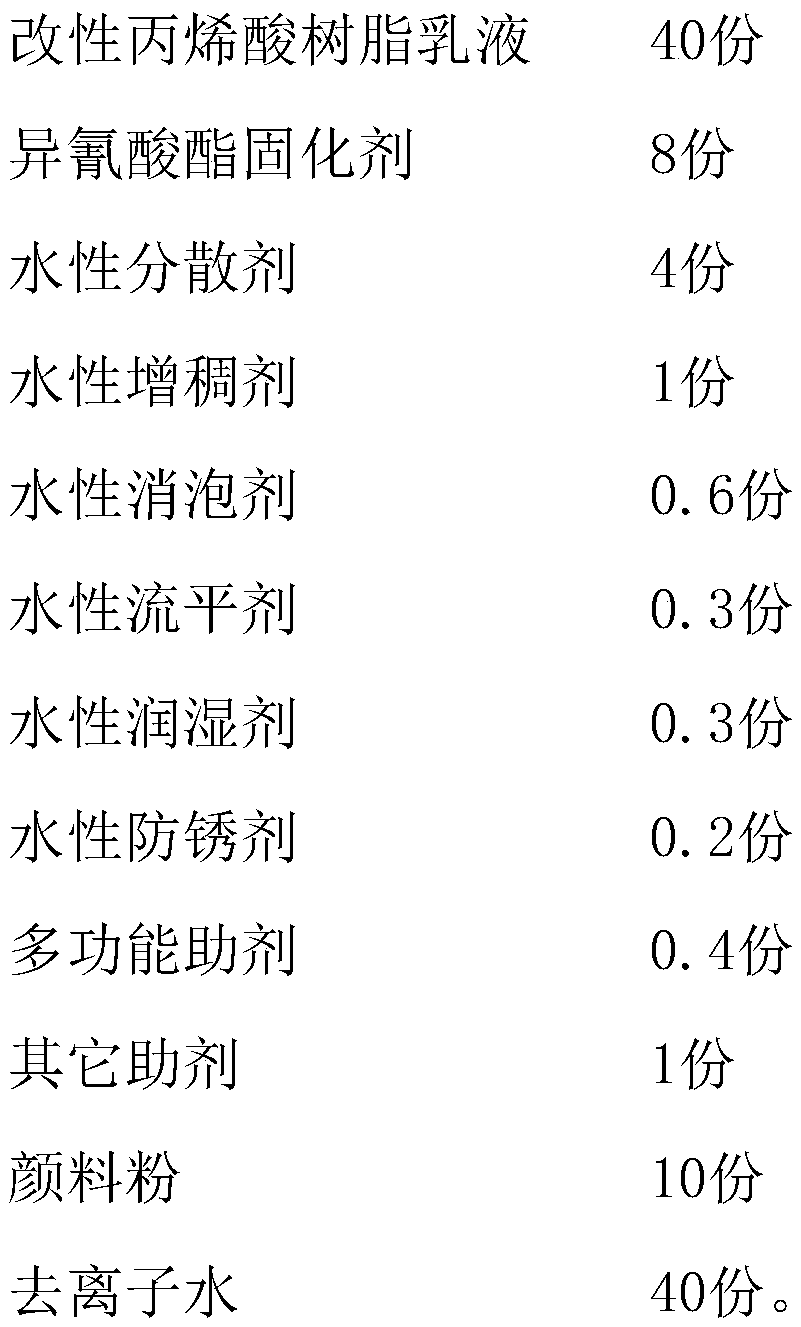

[0126] A kind of water-based plastic coating, described water-based plastic coating comprises the raw material of following weight portion:

[0127]

[0128] The modified acrylic resin emulsion is a silicone modified acrylic resin emulsion with a solid content of 48% and a viscosity of 700mpa.s; A mixture of glycol esters in a weight ratio of 0.6:1:1.8.

[0129] The water-based thickener is a mixture of sodium carboxymethylcellulose, polyurethane thickener and polyacrylic acid saline alkali swelling emulsion in a weight ratio of 1:1:3; the water-based defoamer is made of polyoxypropylene A mixture of oxyethylene glyceryl ether, polydimethylsiloxane and simethicone in a weight ratio of 5:3:1.

[0130] The water-based leveling agent is a mixture composed of polyether modified polydimethylsiloxane, polyether polyester modified organosiloxane and alkyl modified organosiloxane in a weight ratio of 1.8:3:1 ; The water-based wetting agent is a mixture of sodium dodecylsulfonate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com