Flame-retardant polyolefin macromolecule composite material and preparation method thereof

A composite material and polyolefin technology, applied in the field of flame retardant materials, can solve a large amount of hydrogen halide gas, threaten human health, environmental pollution and other problems, achieve high flame retardant performance, high efficiency flame retardant performance, and improve flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A flame-retardant polyolefin polymer composite material, made of the following components in mass percentage:

[0034] components Mass percentage (%) polyethylene 75 Organophosphorus nitrogen flame retardant 20 Ammonium polyphosphate 5

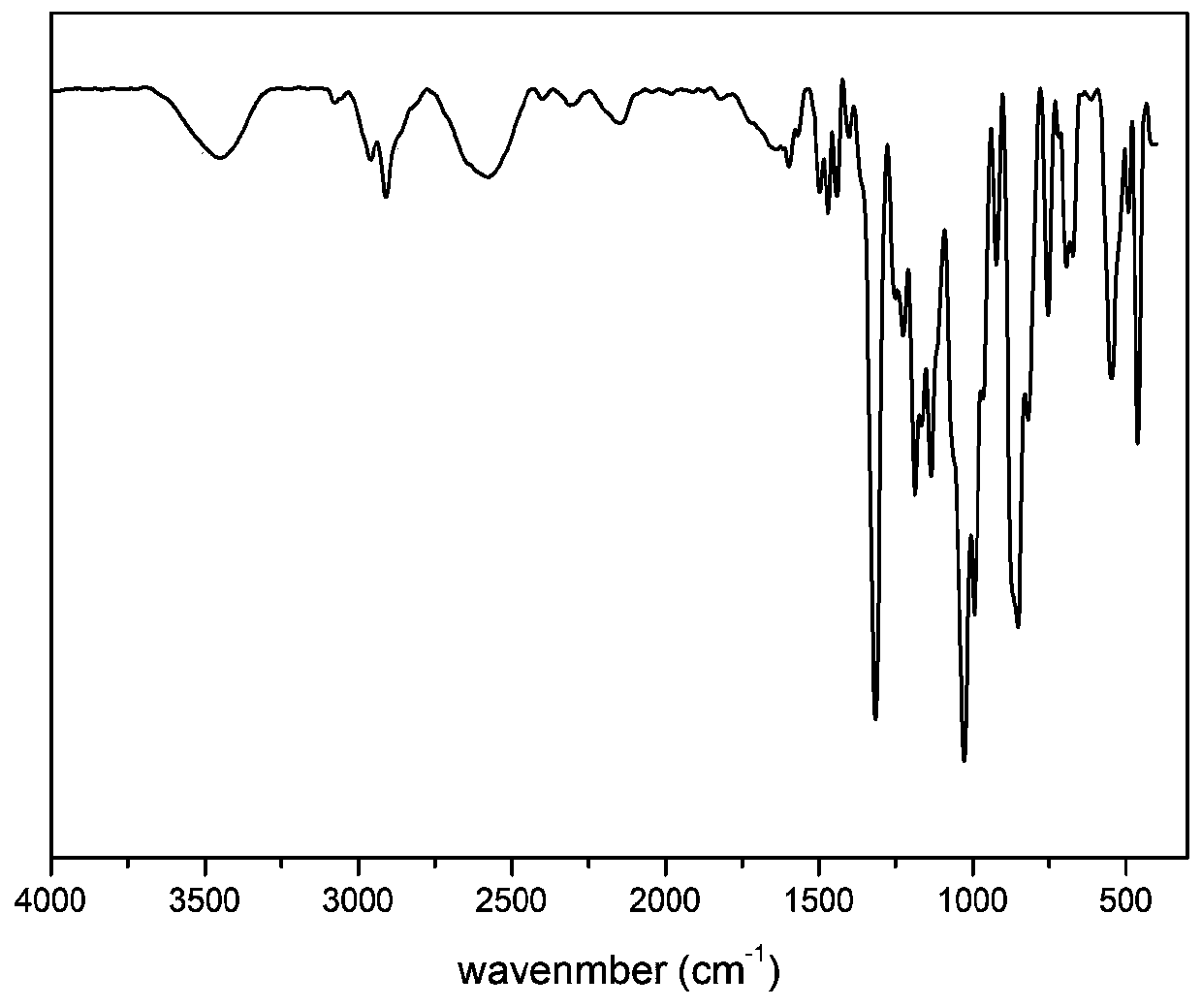

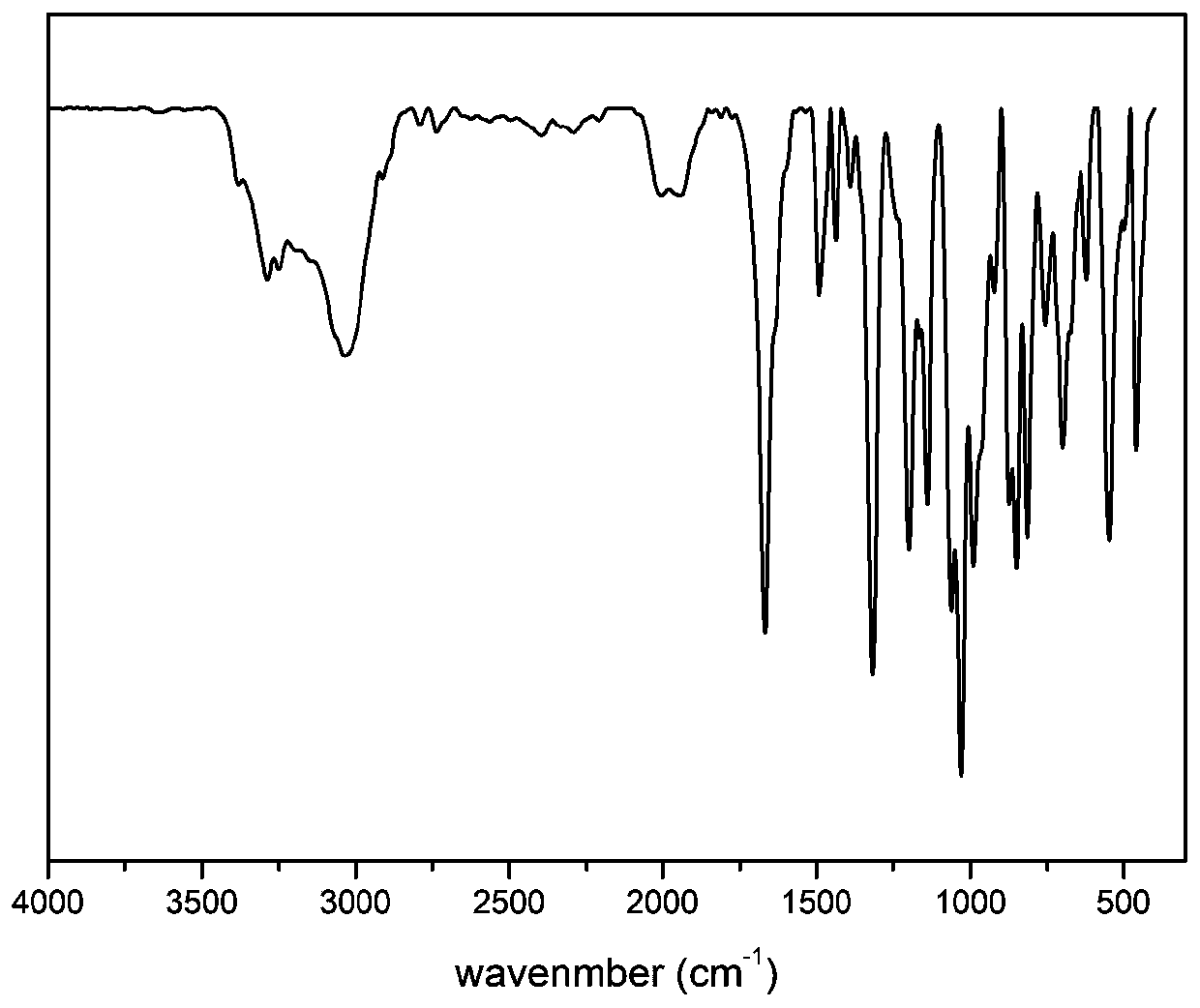

[0035] The preparation of the organophosphorus nitrogen flame retardant: at 10°C, in a nitrogen atmosphere, drop 10.8g of phenylphosphonic dichloride into 200ml of acetonitrile and mix evenly, add 10g of pentaerythritol phosphate into 100ml of acetonitrile, and wait for the pentaerythritol After the phosphate ester is completely dissolved, the pentaerythritol phosphate ester solution is gradually added to the phenylphosphonyl dichloride solution. Raise the temperature to 40°C for 1 hour, then raise the temperature to 50°C for 4 hours; after the reaction, lower the temperature to room temperature, and dry in an oven at 60°C for 24 hours to obtain the intermediate; take 16g of the intermediate and dissolv...

Embodiment 2

[0039] A flame-retardant polyolefin polymer composite material, made of the following components in mass percentage:

[0040] components Mass percentage (%) Polypropylene 75 Organophosphorus nitrogen flame retardant 20 boron nitride 5

[0041] The preparation of the organophosphorus nitrogen flame retardant: under the condition of 20°C, under the nitrogen atmosphere, drop 14.3g of phenylphosphonic dichloride into 200ml of acetonitrile and mix well, pass through nitrogen, add 11g of pentaerythritol phosphate to 150ml In acetonitrile, after the pentaerythritol phosphate is completely dissolved, the pentaerythritol phosphate solution is gradually added to the phenylphosphonyl dichloride. Raise the temperature to 45°C for 2 hours, then raise the temperature to 55°C for 5 hours; after the reaction, lower the temperature to room temperature, and dry in an oven at 60°C for 24 hours to obtain the intermediate; take 11g of the intermediate, dissolve th...

Embodiment 3

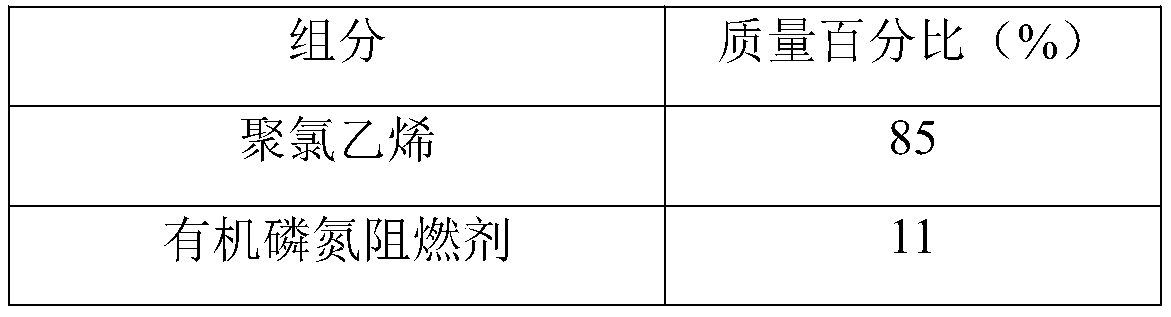

[0045] A flame-retardant polyolefin polymer composite material, made of the following components in mass percentage:

[0046] components Mass percentage (%) polyethylene 80 Organophosphorus nitrogen flame retardant 17 Ammonium polyphosphate 3

[0047]Preparation of the organophosphorus nitrogen flame retardant: at 15°C, 8.7g of phosphorus oxychloride was dropped into 120ml of acetonitrile in a nitrogen atmosphere and mixed evenly, 4.0g of pentaerythritol phosphate was added into 70ml of acetonitrile, and the pentaerythritol After the phosphate ester is completely dissolved, the pentaerythritol phosphate ester solution is gradually added to the phenylphosphonyl dichloride. The temperature was raised to 50°C for 3 hours at the beginning, and then raised to 60°C for 6 hours; after the reaction, the temperature was lowered to room temperature, and dried in an oven at 60°C for 24 hours to obtain the intermediate; 10 g of the intermediate was taken,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com