Polymer film electrolyte of all-solid-state lithium metal battery, preparation method of polymer film electrolyte, and application of polymer film electrolyte in wide temperature range

A polymer film, lithium metal battery technology, used in electrolytes, secondary batteries, circuits, etc., can solve the problems of difficulty in charging and discharging, low ionic conductivity, etc., and achieve a wide electrochemical stability window, high ionic conductivity, Easy to scale up for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is the preparation of polymer film electrolyte, the process is as follows:

[0047] Dissolve polyethylene oxide, succinonitrile and LiTFSI with a molecular weight of 600,000 in acetonitrile solvent, and stir for 24 hours to obtain a uniform solution. Wherein, the concentration of polyethylene oxide in the solution is 6wt.%, the weight of succinonitrile accounts for 30% of the total mass of succinonitrile and polyethylene oxide, and the weight of LiTFSI accounts for 15% of the total mass of LiTFSI and polyethylene oxide. %. Subsequently, the homogeneous solution was transferred to a polytetrafluoroethylene substrate, and vacuum-dried at 40° C. for 48 hours, then taken out to obtain a polymer film electrolyte.

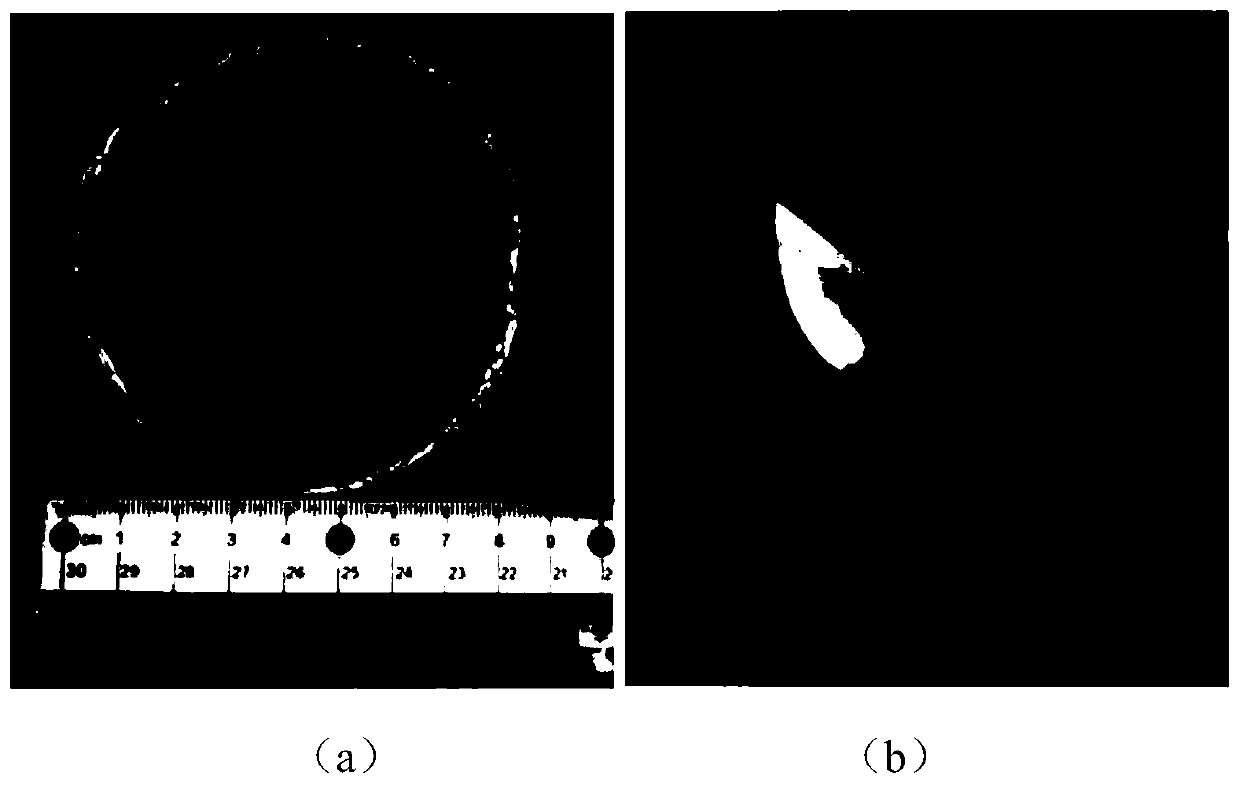

[0048] figure 1 Shown is the physical picture of the polymer film prepared in this embodiment. The polymer film has good flexibility (such as figure 1 (b)), and the preparation process is simple.

Embodiment 2

[0050] This embodiment is the preparation of polymer film electrolyte, the process is as follows:

[0051] Dissolve polyethylene oxide, neopentyl glycol, and LiTFSI with a molecular weight of 600,000 in acetonitrile solvent, and stir for 24 hours to obtain a uniform solution. Wherein, the concentration of polyethylene oxide in the solution is 6wt.%, the weight of neopentyl glycol accounts for 25% of the total mass of neopentyl glycol and polyethylene oxide, and the weight of LiTFSI accounts for 25% of the total mass of LiTFSI and polyethylene oxide. 15%. Subsequently, the homogeneous solution was transferred to a polytetrafluoroethylene substrate, and vacuum-dried at 40° C. for 48 hours, then taken out to obtain a polymer film electrolyte.

Embodiment 3

[0053] This embodiment is the preparation of polymer film electrolyte, the process is as follows:

[0054] Polyethylene oxide, succinonitrile and LiClO with a molecular weight of 600,000 4 Dissolved in acetonitrile solvent, stirred for 24h to obtain a homogeneous solution. Wherein, the concentration of polyethylene oxide in the solution is 6wt.%, and the weight of succinonitrile accounts for 25% of the total mass of succinonitrile and polyethylene oxide, LiClO 4 weight of LiClO 4and 10% of the total mass of polyethylene oxide. Subsequently, the homogeneous solution was transferred to a polytetrafluoroethylene substrate, and vacuum-dried at 40° C. for 48 hours, then taken out to obtain a polymer film electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com