Anti-seepage concrete material in plateau region and preparation method of concrete material

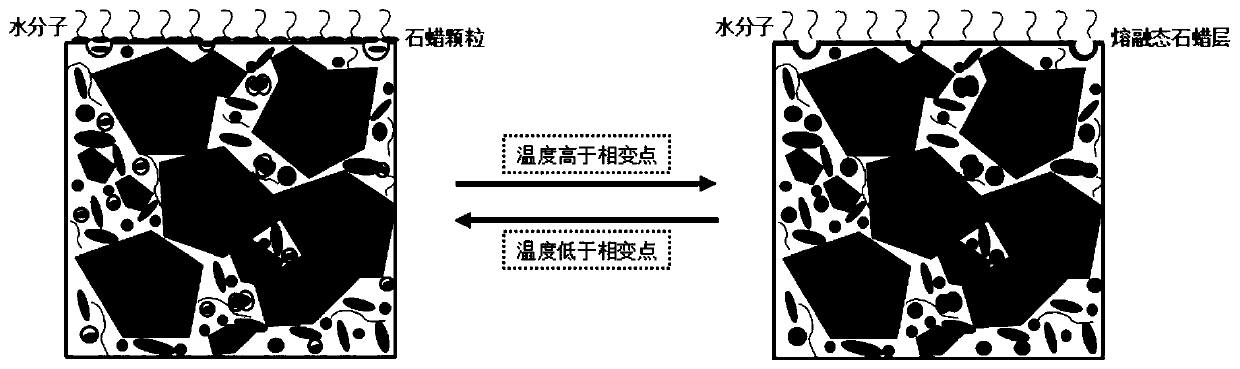

A technology of impervious concrete and plateau, which is applied in the field of civil engineering materials, can solve the problems of affecting the coating quality and adhesion, reducing the mechanical properties of cement concrete, and increasing the cost of concrete, so as to slow down the migration rate of water molecules and maintain thermodynamic stability resistance, anti-sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Plateau anti-seepage emulsion of the present invention, its preparation method comprises the following steps:

[0038]Step 1: Put paraffin, emulsifier, carboxymethyl cellulose calcium, carrageenan and deionized water in a constant temperature water bath, react in a water bath at 58°C to 72°C until the paraffin melts and the temperature reaches a constant temperature, then take it out. First pour deionized water into the colloid mill for pre-running. After the deionized water is completely pre-wetted in the colloid mill, gradually pour paraffin, emulsifier, carboxymethyl cellulose calcium and carrageenan into the colloid mill, and use a glass rod to Stir in one direction to help the colloid mill shear emulsification, cool to room temperature, and make ionic emulsion;

[0039] Step 2: Prepare difenoconazole and pendimethalin into a solution, add active powder under stirring conditions, and disperse evenly by ultrasonic to obtain a suspension;

[0040] Step 3: After mixin...

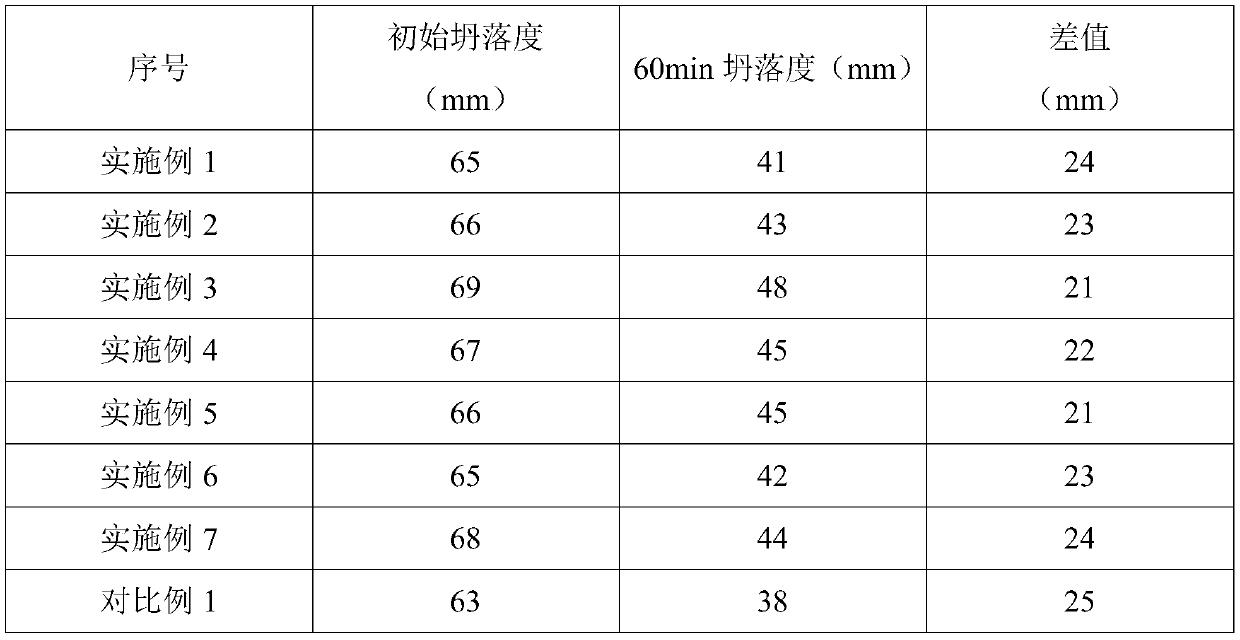

Embodiment 1

[0046] A kind of plateau anti-seepage concrete material described in this example is characterized in that, by mass percentage, be: 19.4% cement, 6.3% water, 68.6% aggregate (41.2% coarse aggregate; 27.4% fine aggregate Material), 1.5% alkaline activator, 0.2% polycarboxylate superplasticizer and 4.0% anionic plateau anti-seepage emulsion.

[0047] Plateau anti-seepage emulsion consists of 30.0% paraffin wax, 3.0% active powder (1.0% silica fume; 1.0% fly ash; 1.0% slag powder), 6.0% alkyl alcohol polyether sulfate KS -360, 2.9% carboxymethylcellulose calcium, 0.4% carrageenan, 1.2% difenoconazole, 0.2% pendimethalin and 56.3% deionized water.

[0048] The basic activator consists of 65.0% Al(OH) by mass percent 3 and 35.0% Ca(OH) 2 mixed.

[0049] Aggregate is composed of fine aggregate with a particle size range of less than 5.0mm and coarse aggregate with a particle size range of 5.0mm to 31.5mm; among them, the fine aggregate is medium sand; the coarse aggregate is grav...

Embodiment 2

[0072] A kind of plateau anti-seepage concrete material described in this example is characterized in that, by mass percentage, be: 19.4% cement, 6.3% water, 68.6% aggregate (41.2% coarse aggregate; 27.4% fine aggregate Material), 1.5% alkaline activator, 0.2% polycarboxylate superplasticizer and 4.0% cationic plateau anti-seepage emulsion.

[0073] The plateau anti-seepage emulsion is composed of 30.0% paraffin wax, 3.0% active powder (1.0% silica fume; 1.0% fly ash; 1.0% slag powder), 6.0% 140-72-7 bromide deca Hexaalkylpyridine, 2.9% carmellose calcium, 0.4% carrageenan, 1.2% difenoconazole, 0.2% pendimethalin and 56.3% deionized water are mixed.

[0074] The basic activator consists of 65.0% Al(OH) by mass percent 3 and 35.0% Ca(OH) 2 mixed.

[0075] Aggregate is composed of fine aggregate with a particle size range of less than 5.0mm and coarse aggregate with a particle size range of 5.0mm to 31.5mm; among them, the fine aggregate is medium sand; the coarse aggregate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com