Method for preparing a sintering-resistant metal catalyst

A metal catalyst and anti-sintering technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve problems such as easy deactivation, and achieve universal application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 30.2 g Cu(NO 3 ) 2 ·3H 2 O and 18.6 g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 100 ml distilled water to obtain 1# mixed solution.

[0021] Weigh 55.1 g of aluminum isopropoxide and place it in a three-necked flask, add 300 ml of water, heat to 80 °C in the electric heating mantle for hydrolysis for 1.0 h, gradually heat up to 95 °C over 30 min, then add 2.3 ml of concentrated nitric acid, and slowly pour The above 1# mixed solution was stirred and refluxed at 95°C for 10 h until a translucent sol was formed. The sol was aged at room temperature for 10 days to obtain jelly-like 2# gel.

[0022] Disperse 2# gel in 300 ml of liquid paraffin, drop an appropriate amount of span80, use a high-shear mixing emulsifier to emulsify the gel and liquid paraffin, and then 2 Under protection, the temperature was raised to 300 °C for 10 h to obtain a slurry catalyst. After the slurry catalyst is centrifuged, take the solid phase and place it in a Soxhlet extractor to extrac...

Embodiment 2

[0028] Weigh 61.2 g Cu(NO 3 ) 2 ·3H 2 O and 37.6 g Zn(NO 3 ) 2 ·6H 2 O, 37.8 g Al 2 (NO 3 ) 3 9H 2 O was dissolved in 100 ml distilled water to obtain 4# mixed solution.

[0029] Weigh 62 g Na 2 CO 3 Dissolve in 100ml of water to obtain 5# solution.

[0030] Pump the 4# mixed solution and the 5# solution into the large beaker at the same flow rate with a liquid pump, and stir at the same time to obtain the co-precipitation catalyst precursor. After the precipitation is completed, let it stand for aging for 2 hours, filter, and wash repeatedly until no Na is present. + , to obtain the 6# catalyst precursor.

[0031] Disperse the 6# catalyst precursor in 300 ml of ethylene glycol, drop an appropriate amount of span80, use a high-shear mixing emulsifier to emulsify the gel and liquid paraffin, and then 2 Under protection, the temperature was raised to 220 °C for 10 h to obtain a slurry catalyst.

[0032] After the slurry catalyst is centrifuged, take the solid phas...

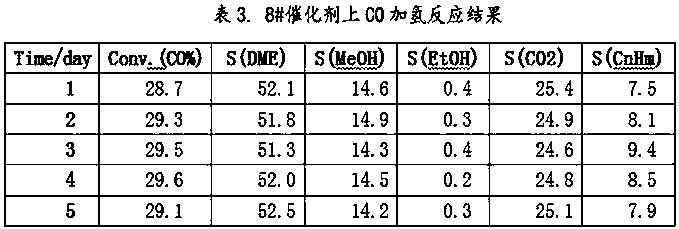

Embodiment 3

[0038] Preparation of Cu-Zn / ZrO by Equal Volume Impregnation Method 2 catalyst. The specific steps are as follows: the Cu(NO 3 )2 •6H 2 O and Zn(NO 3 ) 2 •6H 2 O was dissolved in deionized water and an equal volume was impregnated in ZrO 2 Carrier, magnetically stirred at room temperature for half an hour and allowed to stand for 1 day to obtain 8# catalyst precursor.

[0039] Disperse the 8# catalyst precursor in 300 ml polyethylene glycol-600, use a high-shear mixing emulsifier to emulsify the gel and liquid paraffin, and then 2 Under protection, the temperature was raised to 250 °C for 10 h to obtain a slurry catalyst.

[0040] After the slurry catalyst is centrifuged, the solid phase is placed in a Soxhlet extractor and extracted with a low-boiling organic solvent for a period of time, and the extracted catalyst is placed at room temperature to volatilize the solvent to obtain a catalyst that has been heat-treated in the organic liquid phase.

[0041] Put the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com