Amorphous photonic crystal structure-color material with photocatalytic effect and preparation method thereof

A photonic crystal, photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of strong ultraviolet reflection, limited application, color damage, etc. Efficiency, excellent photocatalytic effect, high color saturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

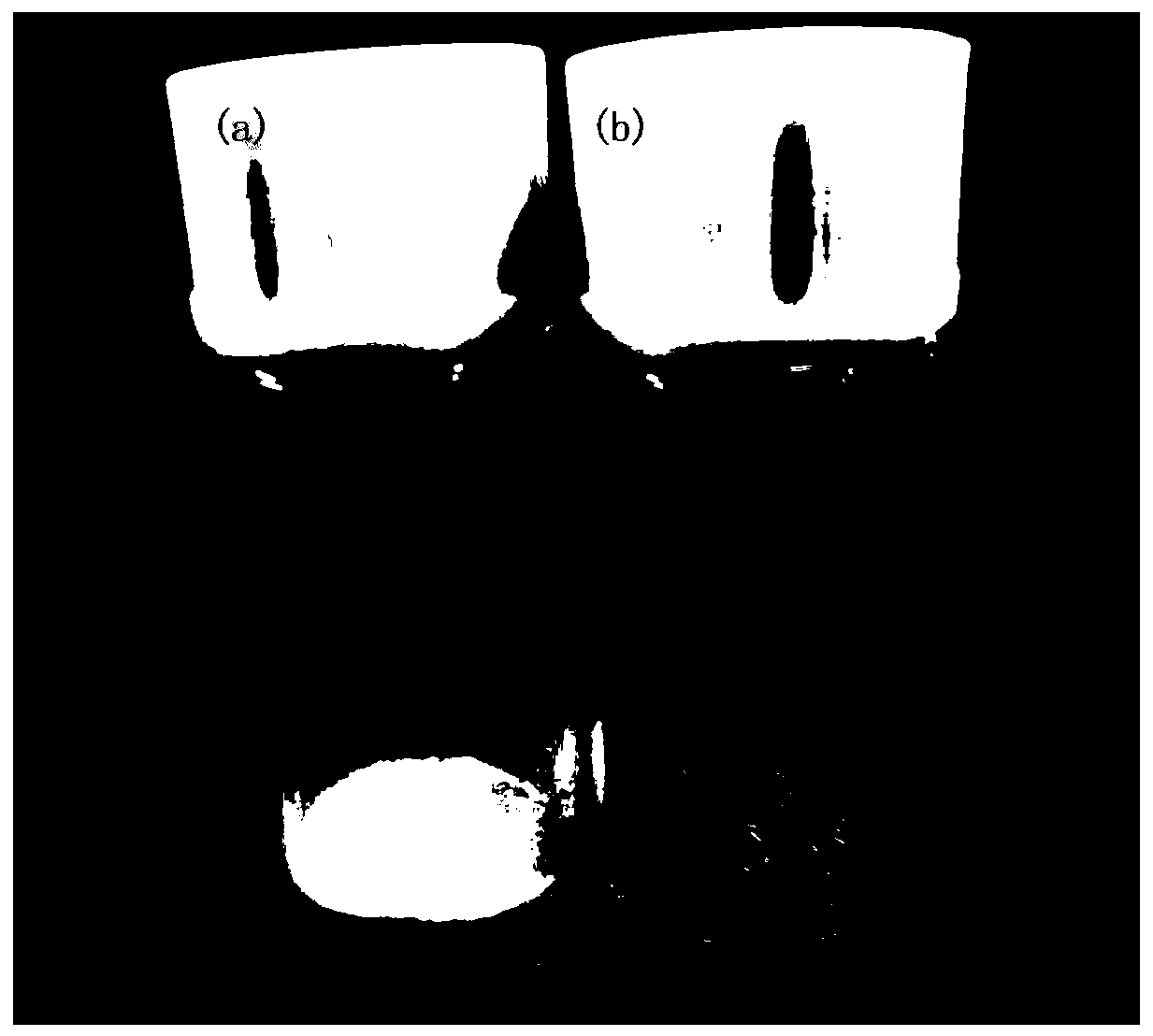

[0032] The preparation method of the amorphous photonic crystal structural color material with photocatalytic effect disclosed by the present invention comprises the following steps:

[0033] 1) SiO with controllable size 2 Preparation of microspheres

[0034] Dissolve ammonia water in absolute ethanol and mix for 0.5h, dissolve ethyl orthosilicate in absolute ethanol and mix for 0.5h, then drop the ethanol solution of tetraethyl orthosilicate into the ethanol solution of ammonia water, so that the concentration of ammonia water is 0.2 -0.8mol / L, the concentration of ethyl orthosilicate is 0.4-1.2mol / L, 25~40℃ constant temperature stirring for 2~8h, after the reaction is completed, centrifuge, wash and dry to obtain SiO 2 microsphere powder.

[0035] 2)SiO2 2 Modification of Microspheres

[0036] SiO with a particle size of 240±5nm 2 The microsphere powder is dispersed in a mixed solution of ethanol and acetonitrile (the volume ratio of ethanol and acetonitrile is 3:1), a...

Embodiment 1

[0041] A method for preparing an amorphous photonic crystal structural color material with photocatalytic effect, comprising the following steps:

[0042] 1) SiO with controllable size 2 Preparation of microspheres

[0043] Mix ammonia water and absolute ethanol at a molar ratio of 1:6 for 1 h, and mix ethyl orthosilicate and absolute ethanol at a molar ratio of 1:10 for 0.5 h, then add ammonia water and absolute ethanol dropwise at a rate of 0.12 mL / min. In the mixed solution of ethanol, stir at 40°C for 2 hours at a constant temperature. After the reaction is completed, centrifuge, wash, and dry to obtain SiO 2 Powder. In the preparation process, the consumption of ammonia water is 0.01mol, and the consumption of ethyl orthosilicate is 0.02mol;

[0044] 2)SiO2 2 Modification of Microspheres

[0045] Weigh 0.2g of SiO with a particle size of 240±5nm 2 The microsphere powder was dispersed in a mixed solution of 100mL ethanol and acetonitrile (volume ratio 3:1), and 0.5mL...

Embodiment 2

[0049] 1) SiO with controllable size 2 Preparation of microspheres

[0050] Mix ammonia water and absolute ethanol at a molar ratio of 1:8 for 1 hour, and mix ethyl orthosilicate and absolute ethanol with a molar ratio of 1:5 for 0.5 h, then add ammonia water and absolute ethanol dropwise at a rate of 0.02 mL / s. In the mixture of ethanol, stir at 36°C for 4h at a constant temperature. After the reaction is completed, centrifuge, wash, and dry to obtain SiO 2 Powder. In the preparation process, the consumption of ammonia water is 0.02mol, and the consumption of ethyl orthosilicate is 0.04mol;

[0051] 2)SiO2 2 Modification of Microspheres

[0052] Weigh 0.25g of SiO with a particle size of 240±5nm 2 The microsphere powder was dispersed in a mixed solution of 100mL ethanol and acetonitrile (volume ratio 3:1), and 0.5mL ammonia water was added at room temperature for ultrasonic mixing to obtain ammonia-modified SiO 2 Emulsion of microspheres;

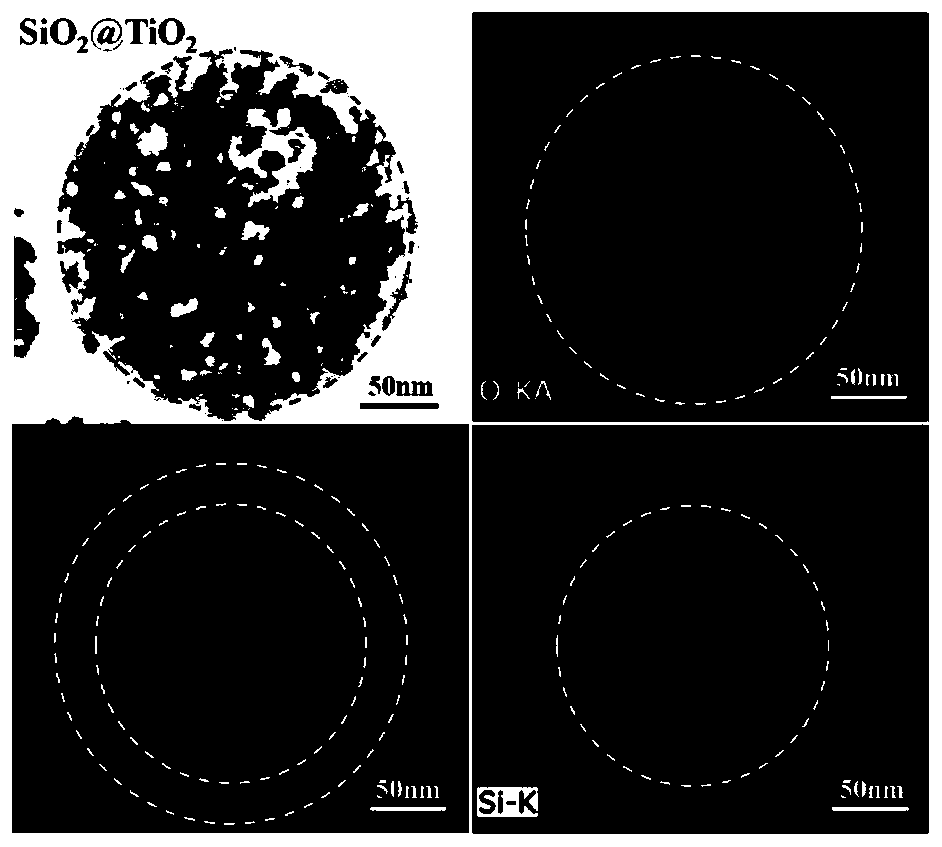

[0053] 3) SiO 2 @TiO 2 mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com