Self-healing composite polymer electrolyte and preparation thereof, and application thereof

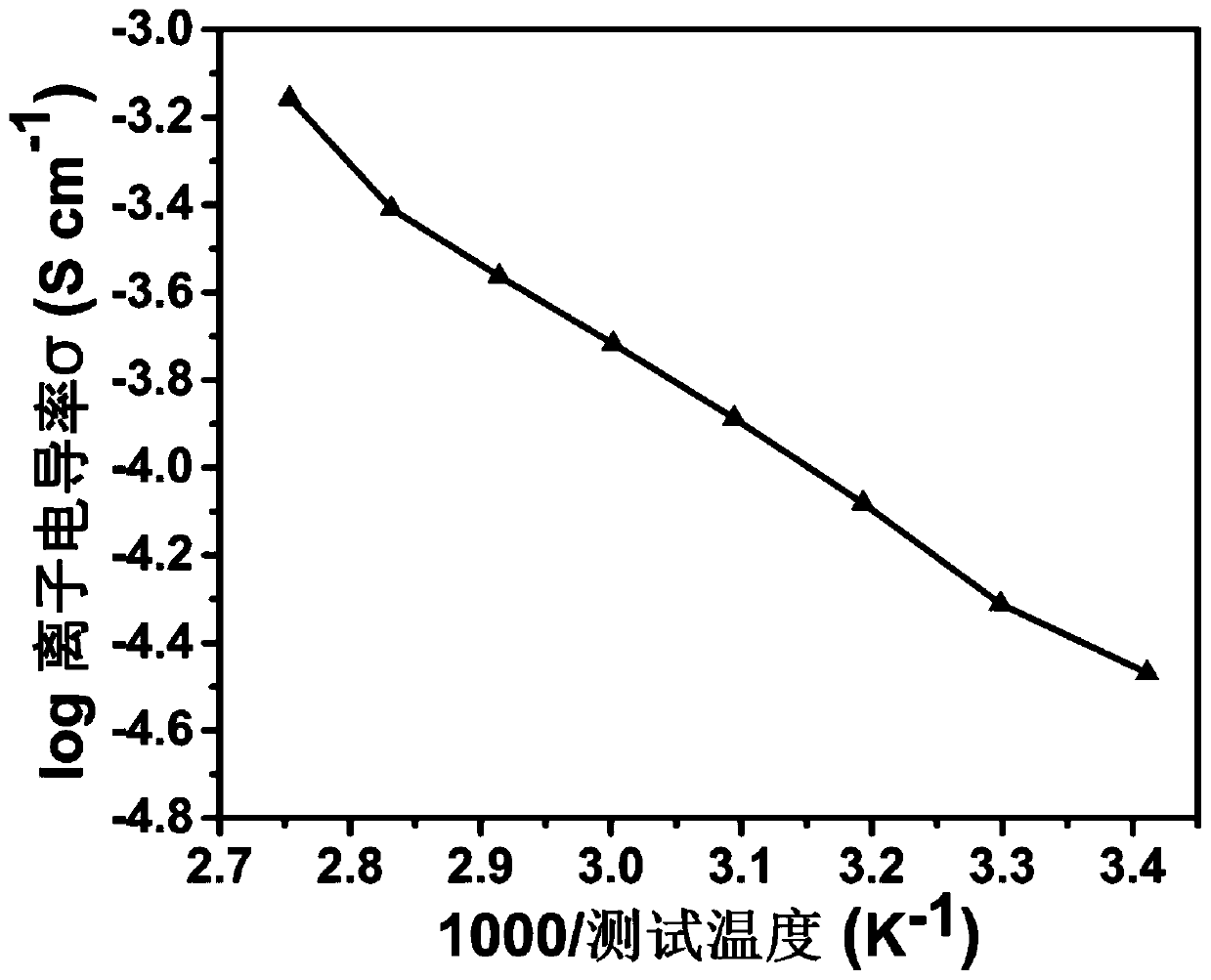

A composite polymer and self-healing technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of decreased conductivity and low ionic conductivity, and achieve improved mechanical properties, high electrochemical properties, and improved electrical properties. The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the composite self-healing polymer electrolyte may include the following steps:

[0044] (1) 2-amino-4-hydroxy-6-methylpyrimidine and 1,6-hexamethylene diisocyanate are placed in a reactor, heated and stirred for reaction, and the reaction product is precipitated, washed and dried to obtain a UPy-NCO compound;

[0045] (2) Disperse tetraethyl orthosilicate in the first solvent, add ammonia water and deionized water, and vigorously stir the reaction at room temperature. The reaction product is centrifuged, washed, and dried to obtain white SiO 2 Nanoparticles;

[0046] (3) the SiO that described step (2) obtains 2 Nanoparticles are ultrasonically dispersed in the second solvent, 3-aminopropyltrimethoxysilane is added dropwise, and the reaction is refluxed at high temperature under the protection of argon. The reaction product is centrifuged, washed, and dried to obtain SiO 2 -NH 2 Nanoparticles;

[0047] (4) the UPy-NCO compound that describ...

Embodiment 1

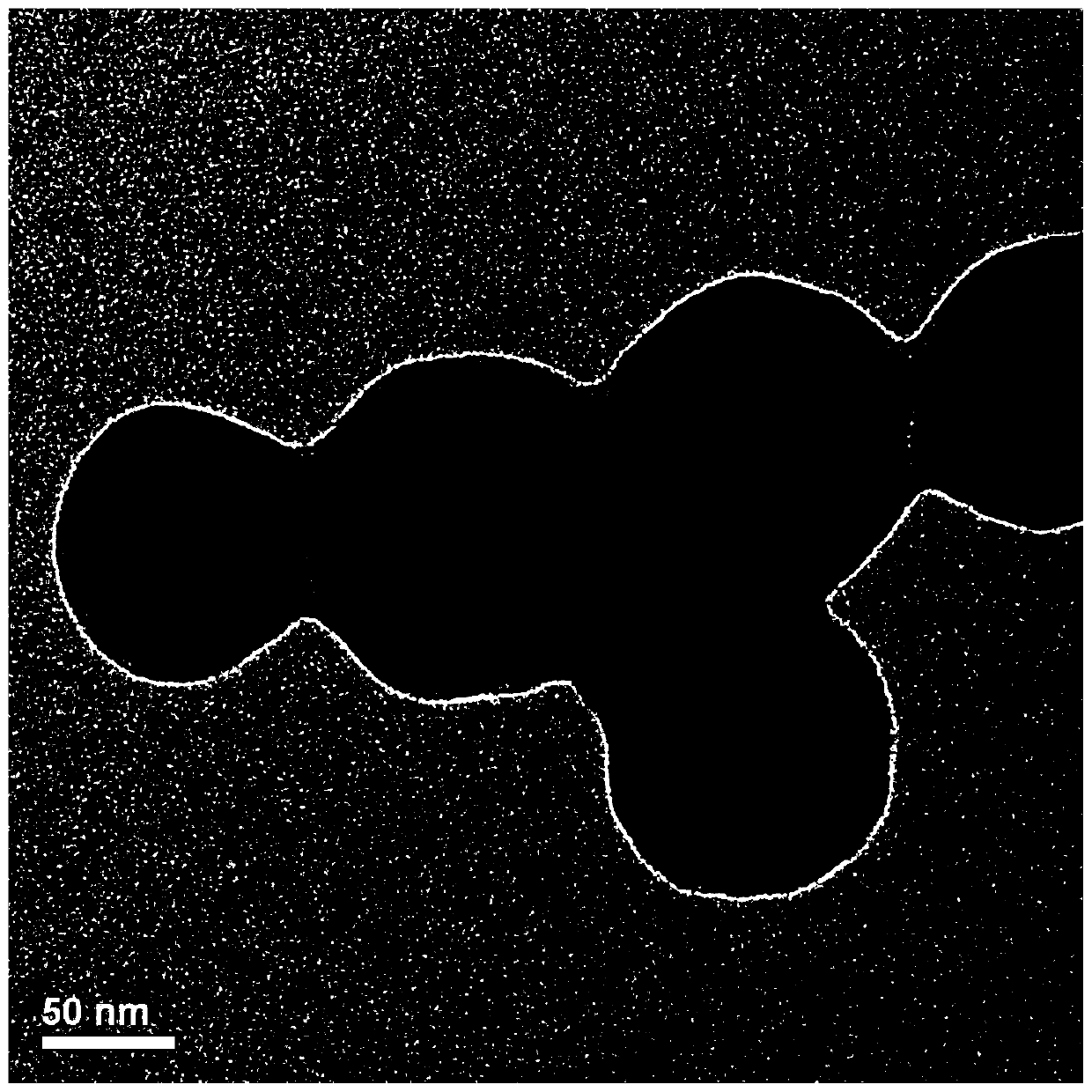

[0057]Add 1.6g of 2-amino-4-hydroxy-6-methylpyrimidine to 2.15g of 1,6-hexamethylene diisocyanate, heat to 80°C to dissolve, react for 16 hours, and precipitate with n-hexane to obtain a white UPy-NCO compound. Mix 6.0g tetraethyl orthosilicate into 30mL ethanol, add 3mL ammonia water and 1.2mL deionized water, stir vigorously at 20°C for 12 hours, centrifuge, wash and dry to obtain silica with a particle size of 50nm Nanoparticles. Take 1.0 g of silica nanoparticles and ultrasonically disperse them in 30 mL of methanol, add 300 μL of 3-aminopropyltrimethoxysilane, heat up to 65 °C under the protection of nitrogen and reflux, react for 12 hours, centrifuge and dry to obtain SiO 2 -NH 2 Nanoparticles.

[0058] Take SiO 2 -NH 2 Dissolve 0.6g of nanoparticles and 0.2g of UPy-NCO compound in 100mL of tetrahydrofuran, add 0.03g of DBTDL catalyst, heat up to 70°C under nitrogen protection, react for 16 hours, centrifuge, wash, and dry to obtain SiO 2 - UPy nanoparticles. The p...

Embodiment 2

[0060] Add 2.2g of 2-amino-4-hydroxy-6-methylpyrimidine into 14.78g of 1,6-hexamethylene diisocyanate, heat to 100°C to dissolve, react for 20 hours, and precipitate through n-hexane to obtain a white UPy-NCO compound. Mix 6.0 g of tetraethyl orthosilicate into 60 mL of acetonitrile, add 6 mL of ammonia water and 3.6 mL of deionized water, stir vigorously for 18 hours, centrifuge, wash, and dry to obtain silica nanoparticles with a particle size of 150 nm. Take 1.0 g of silica nanoparticles and ultrasonically disperse them in 40 mL of ethanol, add 500 μL of 3-aminopropyltrimethoxysilane, heat up to 80 ° C under the protection of argon to reflux, react for 18 hours, centrifuge and dry to obtain SiO 2 -NH 2 Nanoparticles.

[0061] Take SiO 2 -NH 2 Dissolve 0.6g of nanoparticles and 0.6g of UPy-NCO compound in 100mL of dimethyl sulfoxide, add 0.1g of DBTDL catalyst, raise the temperature to 85°C under the protection of argon for 20 hours, centrifuge, wash and dry to obtain SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com