Method for adjusting and controlling coarse second phase of 2219 aluminum alloy ring part

A technology for aluminum alloys and rings, applied in the field of regulating the coarse second phase of 2219 aluminum alloy rings, can solve the problems of difficult diffusion and dissolution of large-sized second phase particles, insufficient diffusion channels of copper elements, and significant dynamic recovery effect. Solve the effect of low local point performance, enhance aging precipitation power, and improve dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

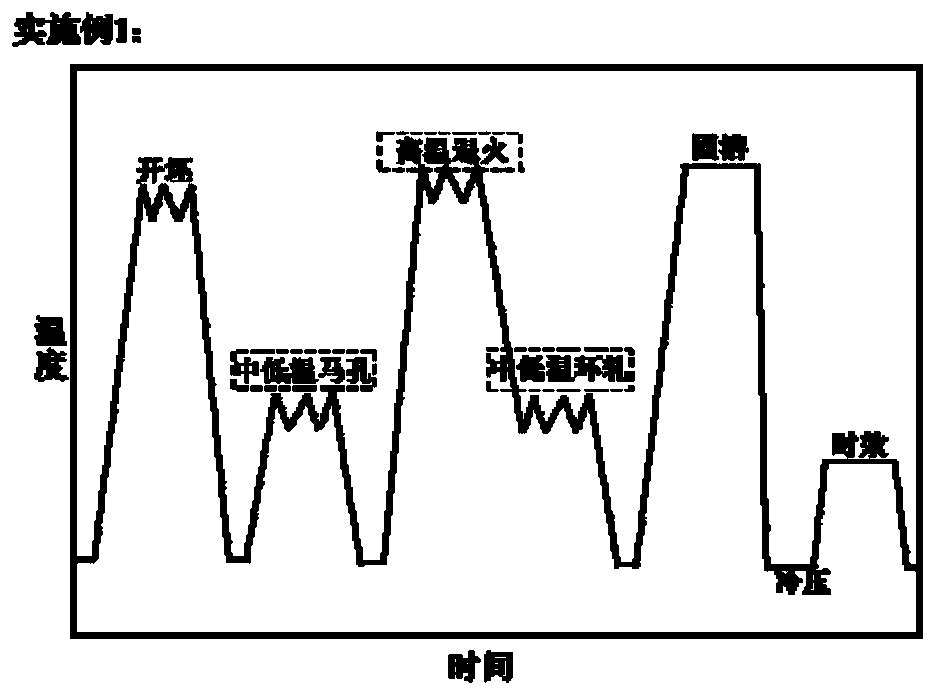

[0036]Embodiment 1 (medium and low temperature expansion + annealing + medium and low temperature ring rolling):

[0037] The present invention regulates the processing method of the coarse second phase of the 2219 aluminum alloy ring, and its manufacturing process is as follows figure 2 As shown, the process flow is as follows image 3 shown, including:

[0038] (1) Multi-directional forging billet: Preheat the 2219 aluminum alloy ingot to 510°C, place it in the press, and adopt the multi-directional forging process of seven upsetting and six drawing (such as figure 1 As shown, the steps in the dotted line box are performed twice), the single upsetting deformation is 65%, the final forging temperature is ≥ 400 ° C, and then the billet is rounded and punched.

[0039] (2) Medium and low temperature saddle reaming: heat the punched 2219 aluminum alloy ring billet to 240°C, transfer it to a press, preheat the mold in contact with the billet to 200°C, and carry out saddle ream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com