Special bismuth stearate-coated lead lanthanum zirconate titanate powder injection molding material and preparation method thereof

A technology of powder injection molding and lead lanthanum zirconate titanate, which is applied in the field of powder injection molding technology and piezoelectric ceramics preparation, can solve problems such as adverse effects on piezoelectric performance and damage to crystal structure, and achieve good piezoelectric performance and doping efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

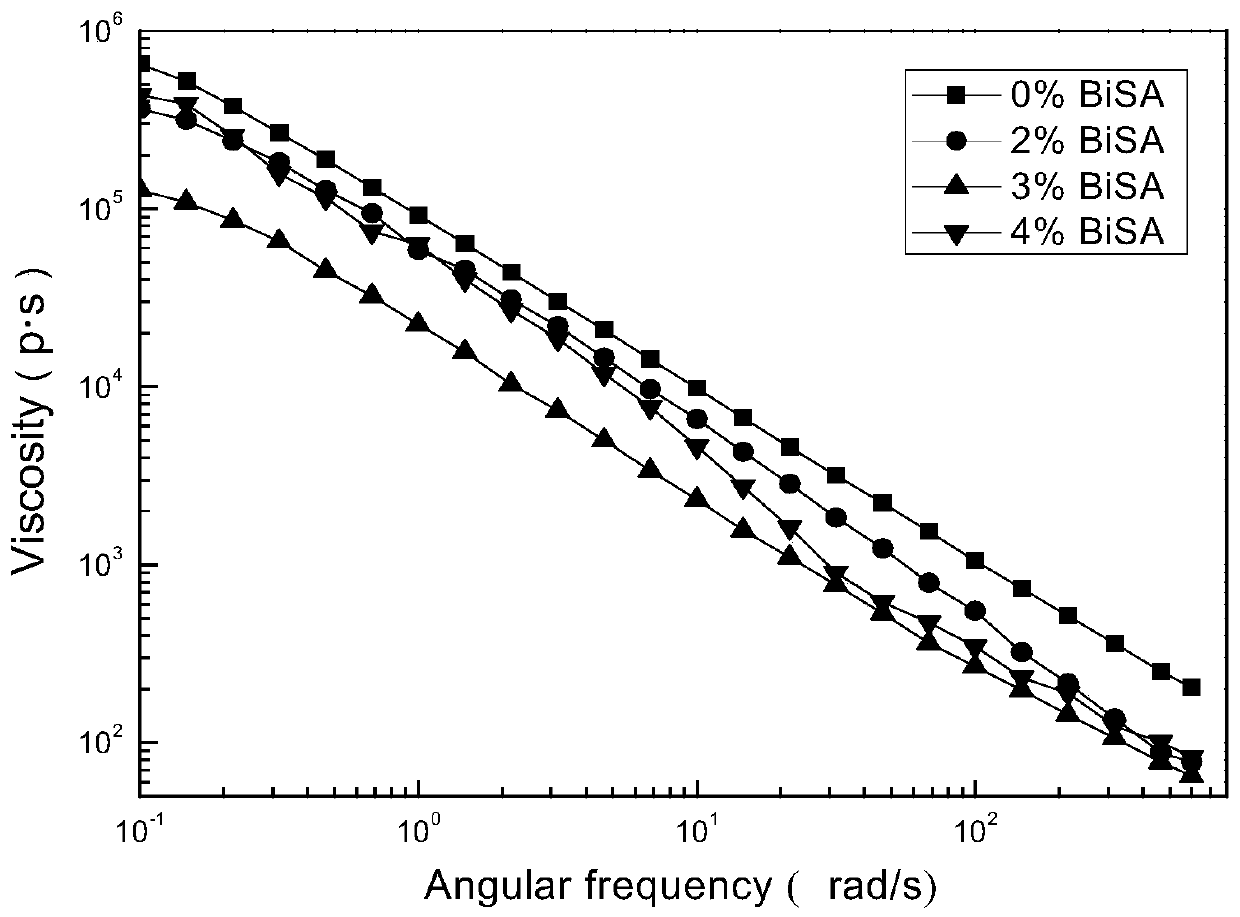

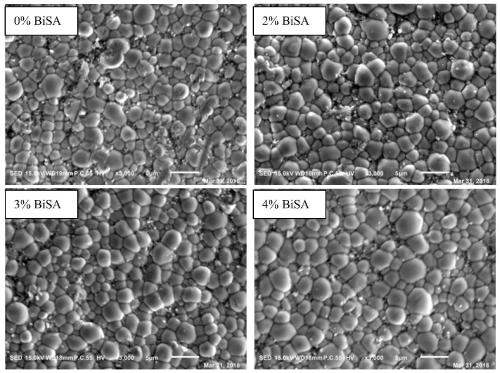

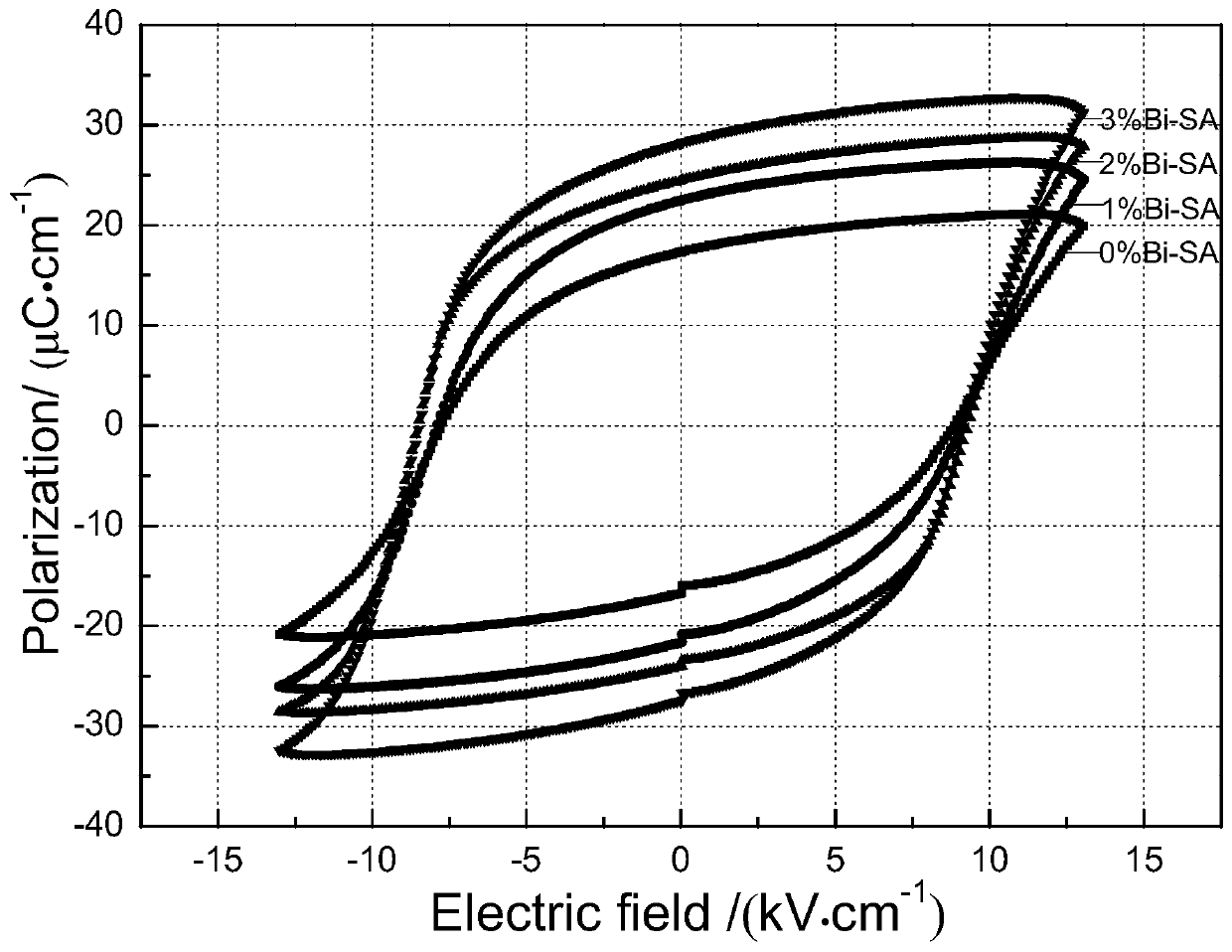

[0028] Bismuth stearate-coated PLZT powder injection molding special material and preparation method, including PLZT powder, powder modifier bismuth stearate and binder, the binder is composed of PEG, PVB, POM and lubricating aid paraffin ; The proportion of each component of the feed: PLZT powder 86.33%, polyethylene glycol (mixed by PEG20000 and PEG1500 in a mass ratio of 1:2) 7.15%, polyvinyl butyral (PVB) 2.15%, polyoxymethylene (POM ) 2.37%, powder modifier bismuth stearate 0.86%, and the balance is paraffin.

[0029] Mix the PLZT powder and bismuth stearate in proportion, and use a high-speed mixer to mix at 120°C for 20 minutes to complete the powder coating modification.

[0030] Mix the modified powder and binder in a certain proportion in the internal mixer evenly. The temperature of the internal mixer is set at 180°C and the speed is 30r / min. Extrusion granulation, temperature setting: 150°C, 160°C, 170°C, 175°C, 180°C, 180°C, 180°C, speed 150rpm, granulation, prep...

Embodiment 2

[0033] Bismuth stearate-coated PLZT powder injection molding special material and preparation method, including PLZT powder, powder modifier bismuth stearate and binder, the binder is mixed with PEG, PVB, POM and lubricant additive PE wax Composition; The ratio of each component of the feeding material: PLZT powder 86.33%, polyethylene glycol (mixed by PEG20000 and PEG1500 in a mass ratio of 1:3) 7.15%, polyvinyl butyral (PVB) 2.15%, polyoxymethylene ( POM) 2.37%, powder modifier bismuth stearate 0.86%, and the balance is PE wax.

[0034] Mix the PLZT powder and bismuth stearate in proportion, and use a high-speed mixer to mix at 120°C for 20 minutes to complete the powder coating modification.

[0035] Mix the modified powder and binder in a certain proportion in the internal mixer evenly. The temperature of the internal mixer is set at 180°C and the speed is 30r / min. Extrusion granulation, temperature setting: 150°C, 160°C, 170°C, 175°C, 180°C, 180°C, 180°C, speed 150rpm, gra...

Embodiment 3

[0038] Bismuth stearate coated PLZT powder injection molding special material and preparation method, including PLZT powder, powder modifier bismuth stearate and binding agent, binding agent is made of PEG, PVB, POM and lubricating aid (paraffin and PE wax mass ratio 1:1 mixed) mixing composition; feeding components ratio: PLZT powder 86.33%, polyethylene glycol (by PEG20000 and PEG1500 mass ratio is 1:2 mixed) 7.15%, polyvinyl butyral Aldehyde (PVB) 2.58%, polyoxymethylene (POM) 2.02%, powder modifier bismuth stearate 3.81%, and the balance is a mixture of paraffin wax and PE wax with a mass ratio of 1:1.

[0039] Mix the PLZT powder and bismuth stearate in proportion, and use a high-speed mixer to mix at 120°C for 20 minutes to complete the powder coating modification.

[0040] Mix the coated and modified powder and binder in a certain proportion in the internal mixer evenly. The temperature of the internal mixer is set at 180°C and the speed is 30r / min. The extruder is ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com