Piezoelectric film, preparation method of piezoelectric film, and piezoelectric film sensor

A piezoelectric thin film and thin film technology, which is applied in the manufacture/assembly of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive devices, etc. To meet the needs of the use of piezoelectric film flexibility, the film is easy to crack and other problems, to achieve the effect of good piezoelectric performance, good piezoelectric performance and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

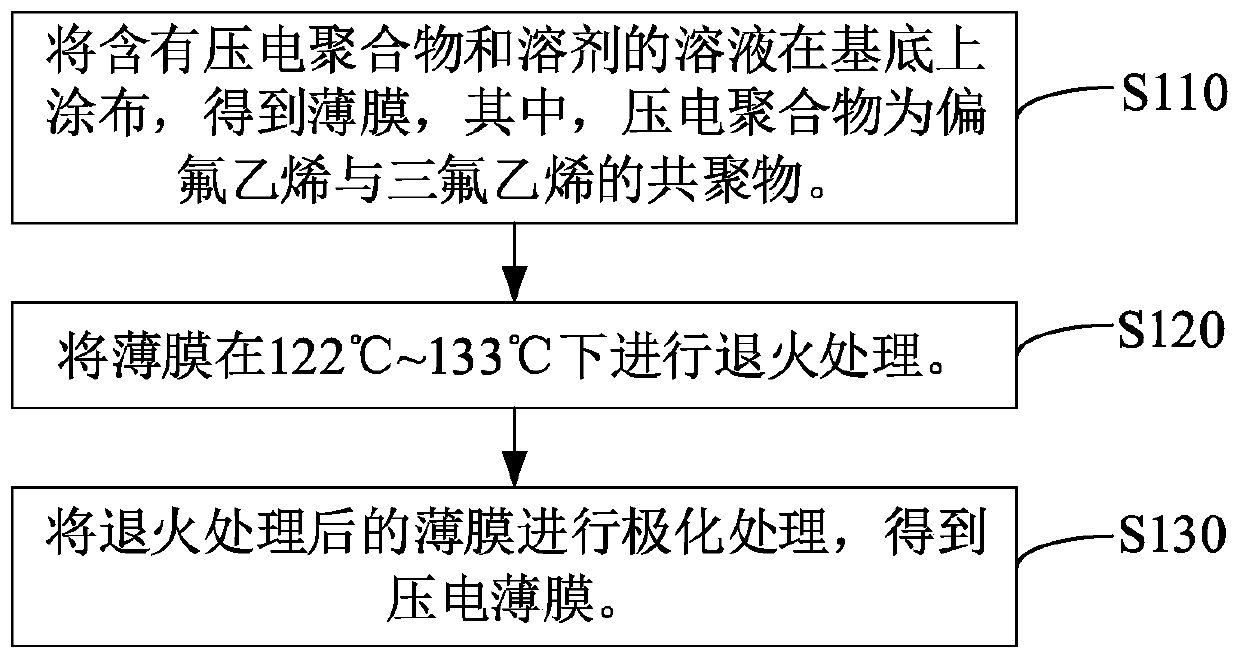

[0026] see figure 1 , the preparation method of the piezoelectric thin film of an embodiment, comprises the following steps:

[0027] Step S110: Coating a solution containing a piezoelectric polymer and a solvent on the substrate to obtain a film, wherein the piezoelectric polymer is a copolymer of vinylidene fluoride and trifluoroethylene.

[0028] Specifically, in one embodiment, the piezoelectric polymer is a copolymer of vinylidene fluoride and trifluoroethylene (P(VDF-TrFE)). In P(VDF-TrFE), the molar ratio of vinylidene fluoride to trifluoroethylene was 80:20. It can be understood that, in other embodiments, the molar ratio of vinylidene fluoride to trifluoroethylene is not limited to the above value, and may also be a copolymer of vinylidene fluoride and trifluoroethylene commonly used in the art.

[0029] Add trifluoroethylene to vinylidene fluoride, because the diameter of fluorine atom in trifluoroethylene is slightly larger than the diameter of hydrogen atom, afte...

Embodiment 1

[0053] The preparation process of the piezoelectric film of the present embodiment is specifically as follows:

[0054] (1) Coating a solution containing a copolymer of vinylidene fluoride and trifluoroethylene and DMAc on ITO glass to obtain a thin film.

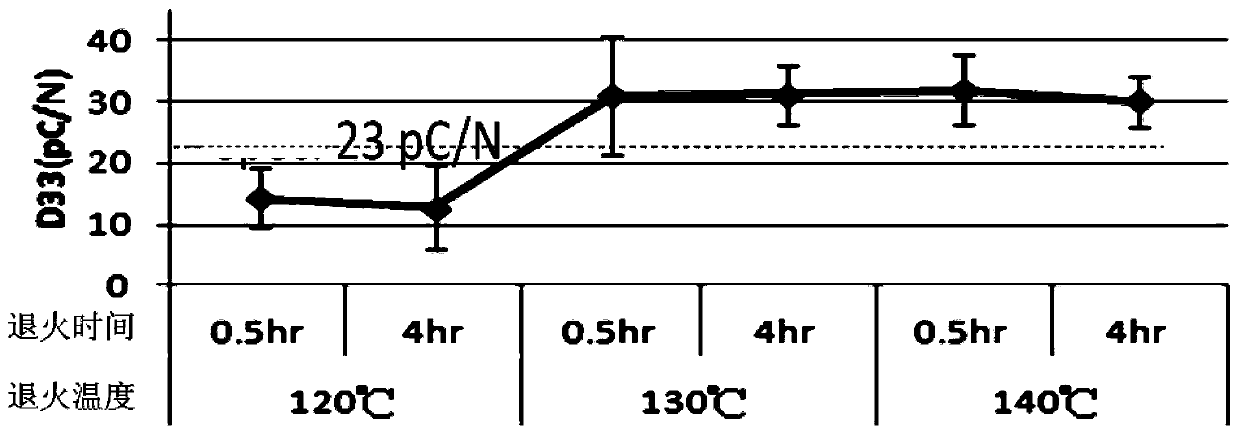

[0055] (2) Annealing the film at 130° C. for 0.5 h, and then performing polarization treatment at room temperature with a polarization electric field of 5 kV and a polarization time of 10 min to obtain a piezoelectric film.

Embodiment 2

[0057] The preparation process of the piezoelectric film of the present embodiment is specifically as follows:

[0058] (1) Coating a solution containing a copolymer of vinylidene fluoride and trifluoroethylene and DMAc on ITO glass to obtain a thin film.

[0059] (2) Perform the first annealing treatment on the film at 125°C for 1 hour, then perform the second annealing treatment at 130°C for 20 minutes, and then conduct the polarization treatment on the annealed film at room temperature, and the polarization electric field is 8kV , the polarization time is 15min, and the piezoelectric film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com