Production method of CoCrMo alloy for artificial joints

A technology for artificial joints and production methods, which is applied to the improvement of process efficiency, tissue regeneration, medical science and other directions, can solve the problems of successful forging without CoCrMo alloy ingots, and achieve the effect of improving production yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

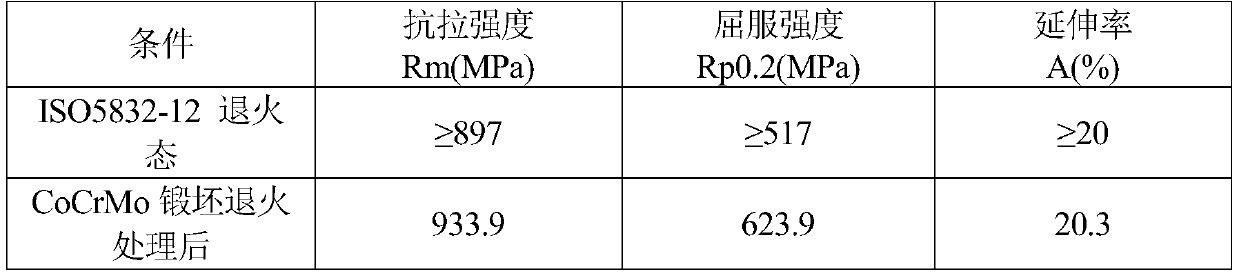

Examples

Embodiment 1

[0039] In the present embodiment, the production method of CoCrMo alloy for artificial joint comprises the following steps:

[0040] 1) Use a pollution-free crucible for vacuum induction furnace melting;

[0041] 2) When selecting materials, metal cobalt (Co99.8wt%), metal chromium (Cr99.95wt%), Mo-1 metal molybdenum and other raw materials in GB / T3462 are used for smelting; vacuumize the combined furnace to 15Pa and start sending Power smelting, keep the vacuum at 25Pa during the smelting process, quickly increase the power to clear after the material turns red, and then maintain this high power to increase the temperature of the molten pool;

[0042] 3) Refining starts when the temperature of the molten pool reaches 1600°C, the refining time is 20min, and the vacuum degree during refining is 15Pa; after that, the nitrogen filling operation is carried out, the nitrogen filling pressure is 54KPa, the nitrogen filling time is 12min, and the nitrogen content is 0.10wt %;

[0043...

Embodiment 2

[0049] In the present embodiment, the production method of CoCrMo alloy for artificial joint comprises the following steps:

[0050] 1) Use a pollution-free crucible for vacuum induction furnace melting;

[0051] 2) When selecting materials, metal cobalt (Co99.8wt%), metal chromium (Cr99.95wt%), Mo-1 metal molybdenum and other raw materials in GB / T3462 are used for smelting; vacuumize the combined furnace to 14Pa and start sending Power smelting, keep the vacuum at 24Pa during the smelting process, quickly increase the power to clear after the material turns red, and then maintain this high power to increase the temperature of the molten pool;

[0052] 3) Refining starts when the temperature of the molten pool reaches 1600°C, the refining time is 30min, and the vacuum degree during refining is 14Pa; after that, the nitrogen filling operation is carried out, the nitrogen filling pressure is 54KPa, the nitrogen filling time is 18min, and the nitrogen content is 0.18wt %;

[00...

Embodiment 3

[0059] In the present embodiment, the production method of CoCrMo alloy for artificial joint comprises the following steps:

[0060] 1) Use a pollution-free crucible for vacuum induction furnace melting;

[0061] 2) When selecting materials, metal cobalt (Co99.8wt%), metal chromium (Cr99.95wt%), Mo-1 metal molybdenum and other raw materials in GB / T3462 are used for smelting; vacuumize the combined furnace to 13Pa and start sending Power smelting, keep the vacuum at 23Pa during the smelting process, quickly increase the power to clear after the material turns red, and then maintain this high power to increase the temperature of the molten pool;

[0062] 3) Refining starts when the temperature of the molten pool reaches 1600°C, the refining time is 25min, and the vacuum degree during refining is 13Pa; after that, the nitrogen filling operation is carried out, the nitrogen filling pressure is 54KPa, the nitrogen filling time is 14min, and the nitrogen content is 0.14wt %;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com