A kind of wide temperature ultra-low loss soft ferrite material and preparation method thereof

A soft magnetic ferrite, ultra-low technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of the total loss of switching power supply, etc., to achieve the effect of improving temperature characteristics and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The above-mentioned preparation method of a wide temperature ultra-low loss soft ferrite material comprises the following steps:

[0048] (1) Mixing of raw materials: After batching according to the set ratio of the four raw materials, use a flip-type vibrating mill to vibrate and grind for 20±2 minutes to fully mix the four raw materials, and the bulk density is controlled at 1.0 ±0.1g / cm 3 within;

[0049] (2) Pelletizing: Put the raw materials mixed by vibrating and milling into the disc pelletizing machine, depending on the dryness of the powder, properly spray deionized water, and use the snowball effect to form the powder into 3-8mm balls. Among them, more than 90% of the balls are required to have a diameter of 3 to 8mm, because too small balls have poor fluidity and the actual pre-burning time of the powder will be long, while too large balls will lead to insufficient pre-burning; ball hardness standard For the free fall at a height of 1.5 meters from the grou...

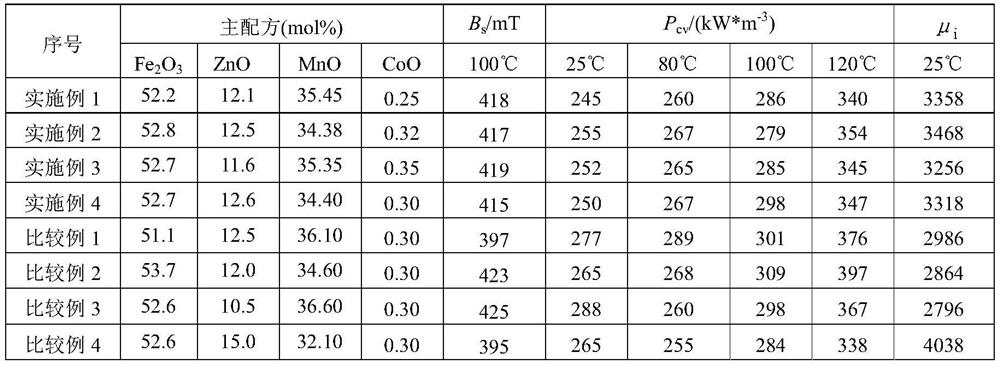

Embodiment 1~4

[0058] A method for preparing a wide temperature ultra-low loss soft ferrite material, the specific steps are as follows:

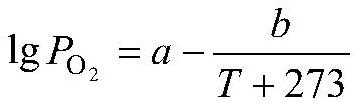

[0059] (1) Mixing of raw materials: the main formula is formulated according to the set mole percentage, wherein, Fe 2 o 3 The content of ZnO is 52.5~53.5mol%, the content of ZnO is 11~13mol%, the content of CoO is 0.1~0.6mol%, and the rest is MnO. Use a flip-type vibrating mill to vibrate and grind for 20±2 minutes to fully grind the three raw materials. Mixing, and the bulk density is controlled at 1.0±0.1g / cm 3 within;

[0060] (2) Pelletizing: Put the raw materials mixed by vibrating and milling into the disc pelletizing machine, depending on the dryness of the powder, properly spray deionized water, and use the snowball effect to form the powder into 3-8mm balls. Among them, it is required that the diameter of the ball is 3-8mm to account for more than 90%, and the hardness standard of the ball is that the free fall of the cement floor (or iron pl...

Embodiment 5~10

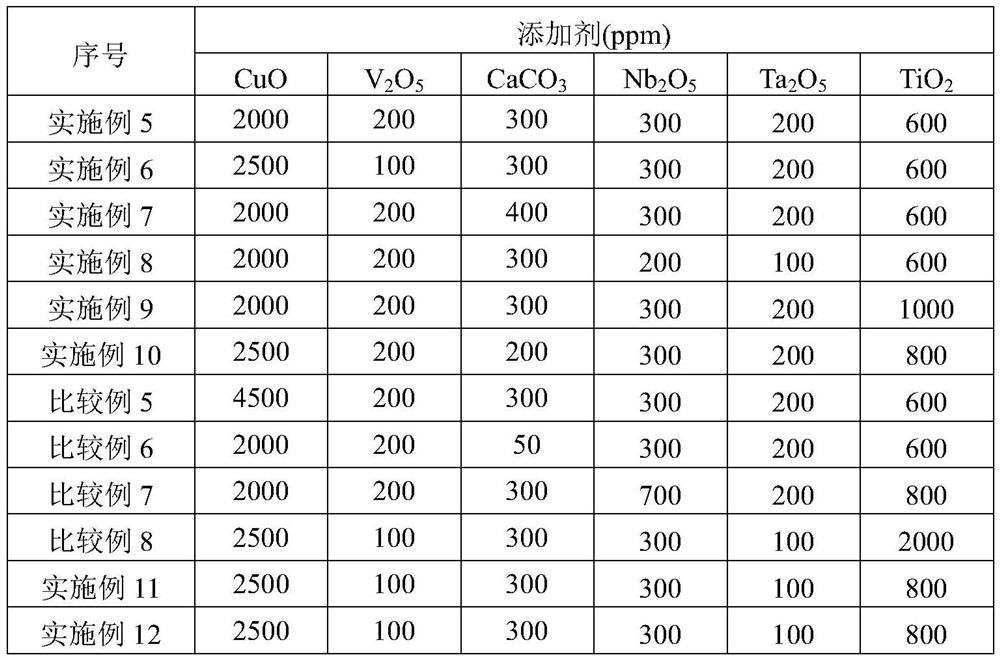

[0071] Embodiments 5 to 10 have the same main formula, wherein Fe 2 o 3 The content of ZnO is 52.8mol%, the content of ZnO is 12.6mol%, the content of CoO is 0.35mol%, and the rest is MnO. The additive combination is shown in Table 2. The corresponding magnetic ring samples are prepared by the preparation process used in Examples 1-4. , to test its electromagnetic properties, the main technical indicators are shown in Table 3. It can be seen from Table 3 that within the scope of the patent of the present invention, the addition amount of the additive combination can meet the technical index requirements of the material.

[0072] Table 2

[0073]

[0074] table 3

[0075]

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com