Titanium-series lithium ion exchanger, and preparation method of precursor thereof

A technology of lithium ion and exchanger, applied in the direction of ion exchange, cation exchange, anion exchange, etc., can solve the problems of poor filtration performance, poor crystal growth environment, affecting product performance, etc., achieve good crystal stability, reduce calcination time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

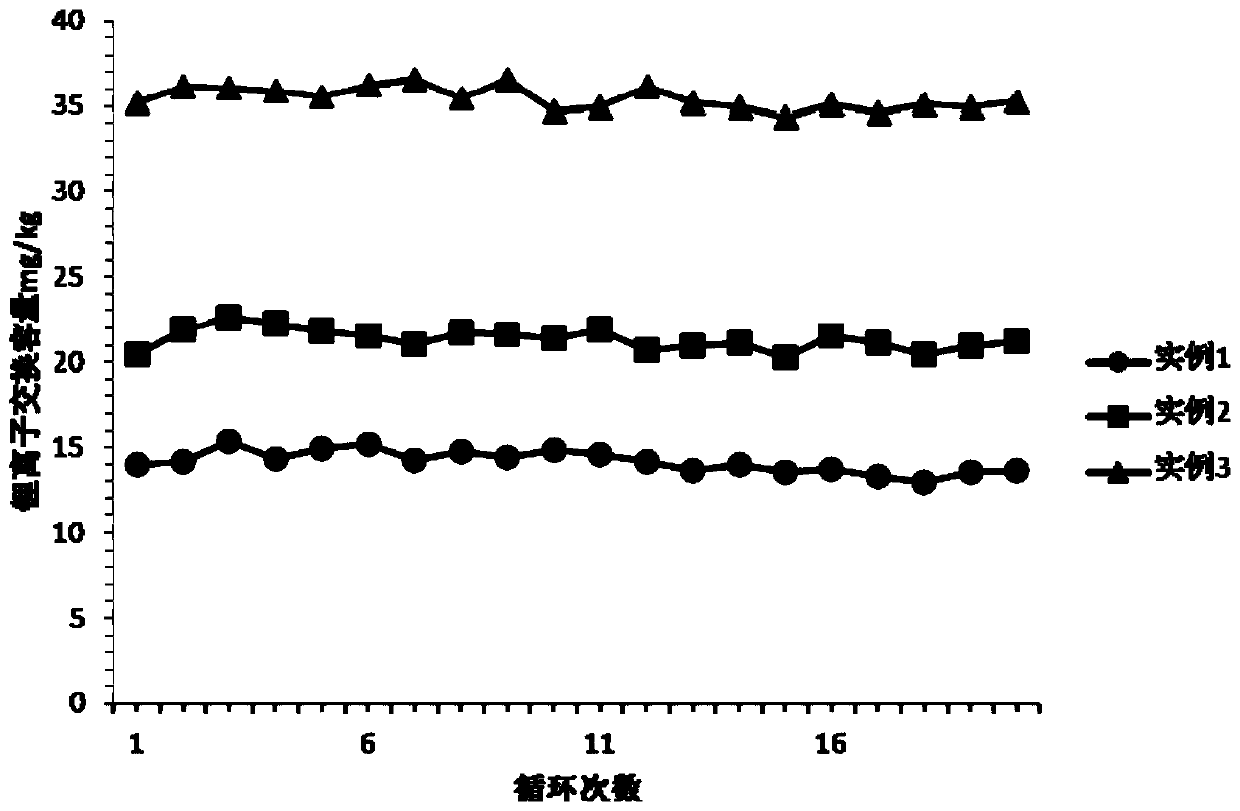

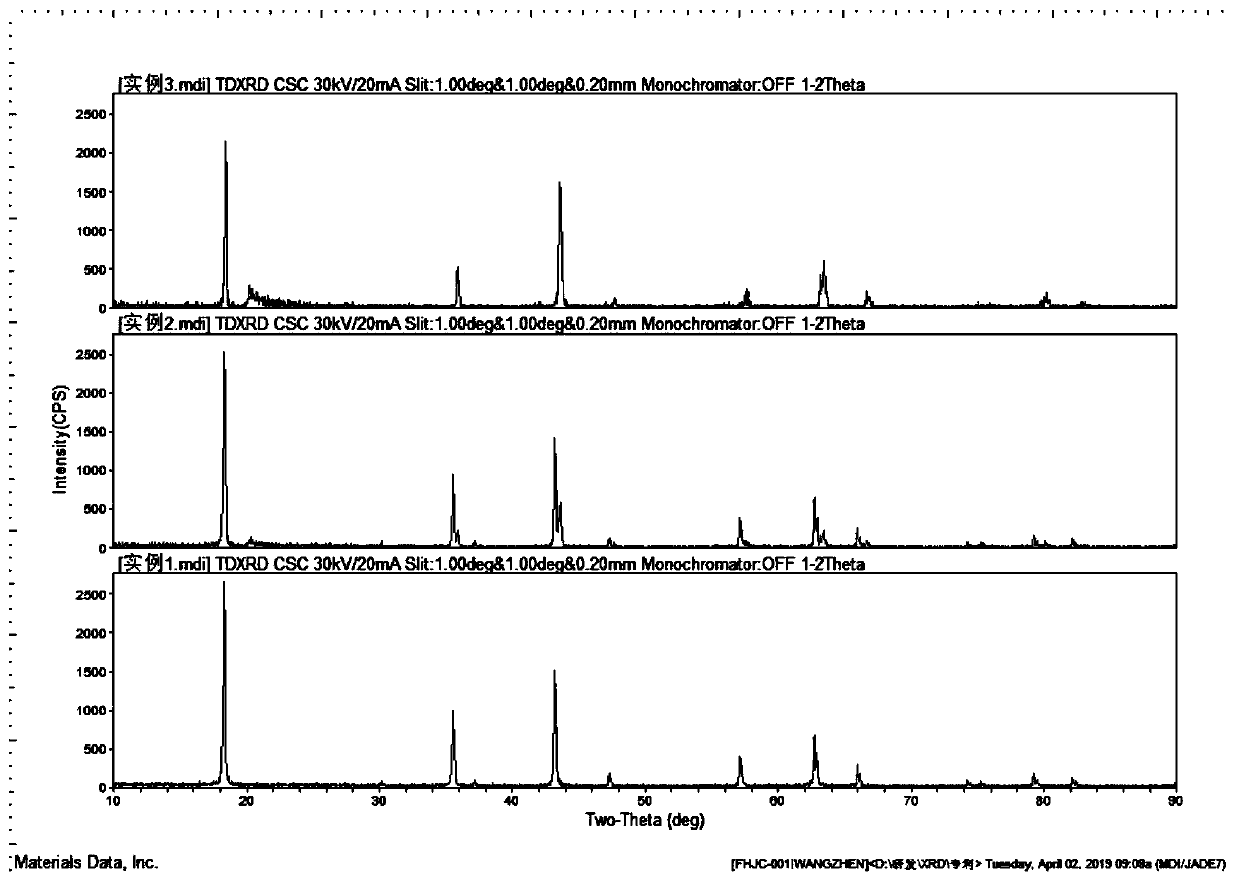

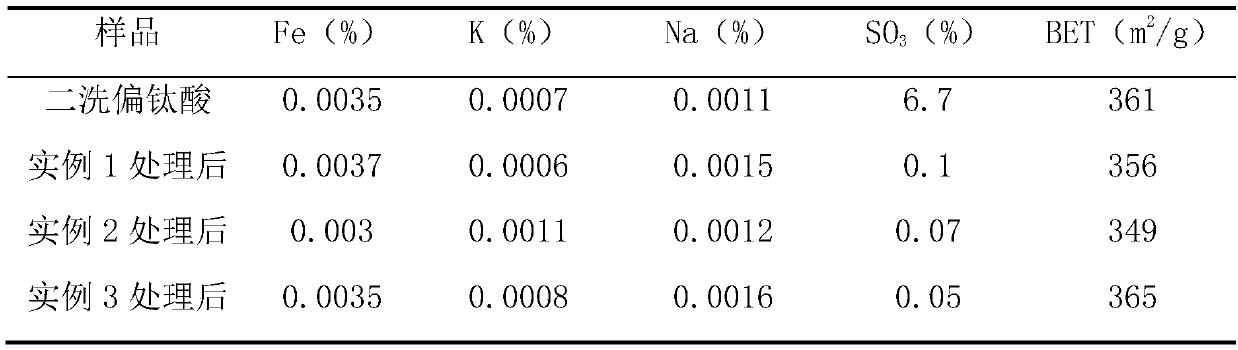

Embodiment 1

[0039] The preparation steps of titanium series lithium ion exchanger precursor include:

[0040] (1) Second washing metatitanic acid (iron content 35ppm) made of TiO with deionized water 2 The slurry with a concentration of 150gL was then adjusted to pH 7.2 with sodium bicarbonate (150g / L) solution, and the temperature was controlled at 40°C for 0.5h of aging.

[0041] (2) Continue to use hydrochloric acid solution (15%) to adjust the pH to 4.1, and after aging for 0.5h, enter the plate frame and wash with water until the conductivity of the effluent is 45 μs / cm to obtain a filter cake;

[0042] (3) The filter cake is beaten with a saturated lithium carbonate solution to make TiO 2 Slurry with a concentration of 300g / L;

[0043] (4) Lithium carbonate is beaten with deionized water to make Li 2 CO 3 Slurry with a concentration of 300g / L, after sand grinding to particle size D50=0.5μm

[0044] (3) The prepared slurry was mixed according to Li:Ti molar ratio=0.8, and stirre...

Embodiment 2

[0048] The preparation steps of titanium series lithium ion exchanger precursor include:

[0049] (1) Second washing metatitanic acid (iron content 30ppm) made of TiO with deionized water 2 The slurry with a concentration of 250gL was then adjusted to pH 9.0 with potassium carbonate (concentration 150g / L) solution, and the temperature was controlled at 50°C for aging for 1h.

[0050] (2) Continue to use phosphoric acid solution (10%) to adjust the pH to 5.5, and after aging for 1 hour, enter the plate frame and wash with water until the conductivity of the effluent is 41 μs / cm to obtain a filter cake;

[0051] (3) The filter cake is beaten with a saturated lithium carbonate solution to make TiO 2 Slurry with a concentration of 400g / L;

[0052] (4) Lithium carbonate is beaten with deionized water to make Li 2 CO 3 The slurry with a concentration of 500g / L is sand-milled until the particle size D50=1 μm, and then the slurry prepared in step (3) is mixed according to the Li:T...

Embodiment 3

[0056] The preparation steps of titanium series lithium ion exchanger precursor include:

[0057] (1) Second washing metatitanic acid (iron content 50ppm) made of TiO with deionized water 2 The slurry with a concentration of 350gL was then adjusted to pH 12 with a sodium hydroxide (concentration 150g / L) solution, and the temperature was controlled at 60°C for 2 hours of aging.

[0058] (2) Continue to use nitric acid solution (15%) to adjust the pH to 6.5, and after aging for 2 hours, enter the plate frame and wash with water until the conductivity of the effluent is 48 μs / cm to obtain a filter cake;

[0059] (3) The filter cake is beaten with a saturated lithium carbonate solution to make TiO 2 Slurry with a concentration of 500g / L;

[0060] (4) Lithium carbonate is beaten with deionized water to make Li 2 CO 3 The slurry with a concentration of 500g / L is sand-milled until the particle size D50=5 μm, and then the slurry prepared in step (3) is mixed according to the Li:Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com