Negative temperature coefficient thermosensitive film and preparation method thereof

A negative temperature coefficient, thermal film technology, applied in resistors with negative temperature coefficient, resistor manufacturing, ion implantation plating and other directions, can solve the development and application of negative temperature coefficient thermal film, low thermal constant, etc. problems, to achieve the effect of improving thermal performance, high thermal performance, and high negative temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

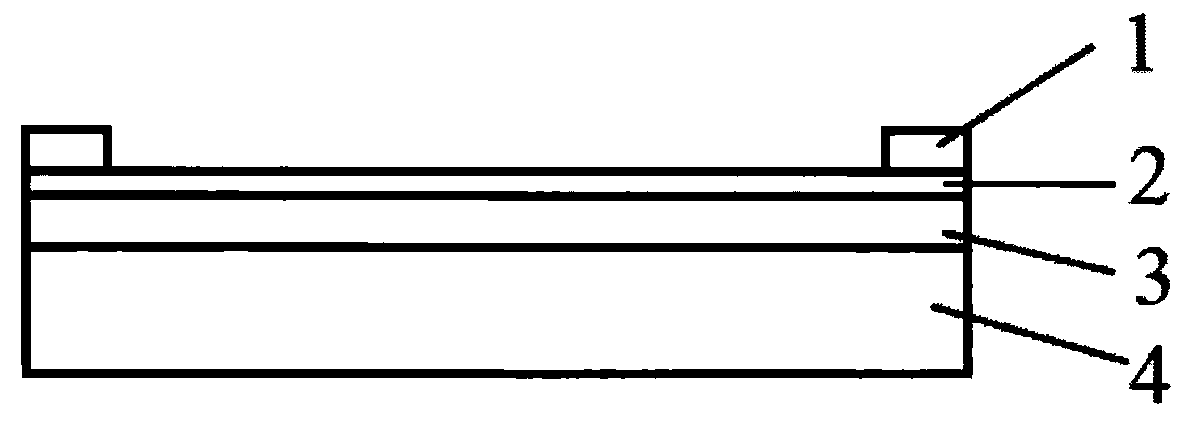

[0031] a. Substrate pretreatment: Firstly, immerse the purchased silicon substrate 4 in acetone, absolute ethanol, deionized water and absolute ethanol in order to perform ultrasonic cleaning for 4 times, each washing time is 5 minutes, and take out the silicon substrate 4 , using high-purity nitrogen to dry the surface of the silicon substrate 4 to obtain a pretreated silicon substrate 4;

[0032] b. Pretreatment of Mn-Co-Ni-Mg-Al alloy target: select Mn-Co-Ni-Mg according to the molar content ratio of Mn, Co, Ni, Mg and Al as 2.1:2.4:1.0:4:1 -Al alloy target material, grinding the surface of the Mn-Co-Ni-Mg-Al alloy target material, removing the surface oxide layer, and obtaining the pretreated Mn-Co-Ni-Mg-Al alloy target material;

[0033] c. Mn-Co-Ni-Mg-Al-based primary thin film preparation: using magnetron sputtering DC sputtering method, the atmosphere of magnetron sputtering DC sputtering is argon atmosphere; magnetron sputtering DC sputtering chamber The air pressure...

Embodiment 2

[0038] a. Substrate pretreatment: firstly, immerse the purchased silicon substrate 4 in acetone, absolute ethanol, deionized water and absolute ethanol in order to perform ultrasonic cleaning for 4 times, each washing time is 10 minutes, and take out the silicon substrate 4 , using high-purity nitrogen to dry the surface of the silicon substrate (4) to obtain a pretreated silicon substrate 4;

[0039] b. Pretreatment of Mn-Co-Ni-Mg-Al alloy target: select Mn-Co-Ni-Mg according to the molar content ratio of Mn, Co, Ni, Mg and Al as 2.1:2.4:1.0:4:1 -Al alloy target material, grinding the surface of the Mn-Co-Ni-Mg-Al alloy target material, removing the surface oxide layer, and obtaining the pretreated Mn-Co-Ni-Mg-Al alloy target material;

[0040] c. Mn-Co-Ni-Mg-Al-based primary thin film preparation: using magnetron sputtering DC sputtering method, the atmosphere of magnetron sputtering DC sputtering is argon atmosphere; magnetron sputtering DC sputtering chamber The air press...

Embodiment 3

[0045] a. Substrate pretreatment: First, immerse the purchased silicon substrate 4 in acetone, absolute ethanol, deionized water and absolute ethanol in order to perform ultrasonic cleaning for 4 times, each washing time is 8 minutes, and take out the silicon substrate 4 , using high-purity nitrogen to dry the surface of the silicon substrate 4 to obtain a pretreated silicon substrate 4;

[0046] b. Pretreatment of Mn-Co-Ni-Mg-Al alloy target: select Mn-Co-Ni-Mg according to the molar content ratio of Mn, Co, Ni, Mg and Al as 2.1:2.4:1.0:4:1 -Al alloy target material, grinding the surface of the Mn-Co-Ni-Mg-Al alloy target material, removing the surface oxide layer, and obtaining the pretreated Mn-Co-Ni-Mg-Al alloy target material;

[0047] c. Preparation of Mn-Co-Ni-Mg-Al-based primary thin film: adopt magnetron sputtering DC sputtering method, the atmosphere of magnetron sputtering DC sputtering is argon atmosphere; the chamber of magnetron sputtering DC sputtering The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com