A method of extracting gold from waste circuit boards

A waste circuit board and extraction technology, which is applied in the direction of improving process efficiency, can solve the problems of high gold recovery cost and low recovery rate, and achieve the effect of fast leaching time, low cost and high gold leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

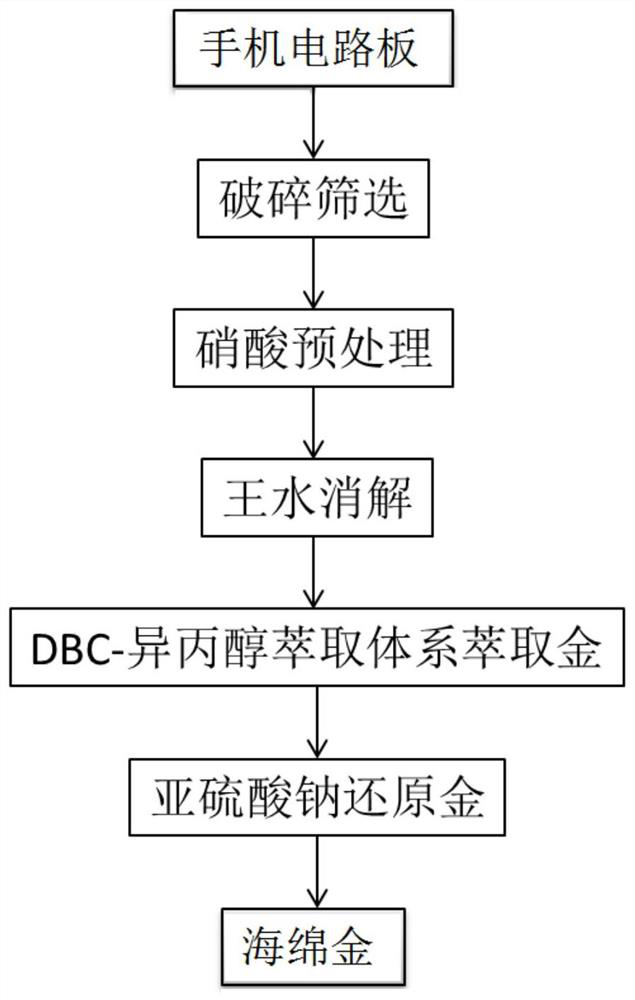

[0026] A method for extracting gold from waste circuit boards, the process flow chart is as follows figure 1 As shown, five parts including physical pretreatment, chemical pretreatment, immersion in aqua regia, gold extraction by DBC-isopropanol extraction system and reduction of gold by sodium sulfite, specifically include the following steps:

[0027] (1) Physical pretreatment: 11 waste mobile phones purchased from the market were manually disassembled to obtain waste circuit boards, and the mobile phone circuit boards were crushed into powder by using a high-speed multifunctional pulverizer. Screen with a 35-mesh national unified standard inspection sieve, and obtain 200 g of a powder sample with a particle size of less than 0.500 mm after screening, which is the gold-containing material powder.

[0028] (2) Chemical pretreatment: Put 1.0000g of gold-containing material powder in a small beaker, add excess HNO 3 The solution was placed in a digital display constant tempera...

Embodiment 2

[0034] A method for extracting gold from waste circuit boards, the process flow chart is as follows figure 1 As shown, five parts including physical pretreatment, chemical pretreatment, immersion in aqua regia, gold extraction by DBC-isopropanol extraction system and reduction of gold by sodium sulfite, specifically include the following steps:

[0035] (1) Physical pretreatment: 11 waste mobile phones purchased from the market were manually disassembled to obtain waste circuit boards, and the mobile phone circuit boards were crushed into powder by using a high-speed multifunctional pulverizer. Screen with a 35-mesh national unified standard inspection sieve, and obtain 200 g of a powder sample with a particle size of less than 0.500 mm after screening, which is the gold-containing material powder.

[0036] (2) Chemical pretreatment: Put 1.0000g of gold-containing material powder in a small beaker, add excess HNO 3 The solution was placed in a digital display constant tempera...

Embodiment 3

[0042] A method for extracting gold from waste circuit boards, the process flow chart is as follows figure 1 As shown, five parts including physical pretreatment, chemical pretreatment, immersion in aqua regia, gold extraction by DBC-isopropanol extraction system and reduction of gold by sodium sulfite, specifically include the following steps:

[0043](1) Physical pretreatment: 11 waste mobile phones purchased from the market were manually disassembled to obtain waste circuit boards, and the mobile phone circuit boards were crushed into powder by using a high-speed multifunctional pulverizer. Screen with a 35-mesh national unified standard inspection sieve, and obtain 200 g of a powder sample with a particle size of less than 0.500 mm after screening, which is the gold-containing material powder.

[0044] (2) Chemical pretreatment: Put 1.0000g of gold-containing material powder in a small beaker, add excess HNO 3 The solution was placed in a digital display constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com