Method for separating tetravalent cerium, thorium and rare earth

A rare earth and solid-state separation technology, which is applied in the field of thorium and rare earth and tetravalent cerium separation, can solve the problem that the medium can only be nitric acid, etc., and achieve the effects of strong extraction ability, elimination of influence, shortening the separation process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0143] In order to further illustrate the solutions of the present invention, specific examples of the present invention are provided to help those skilled in the art understand and implement the present invention, but the present invention is not limited to these examples.

[0144] Reagents and sources

[0145]Diethylhexyl phosphite, di-n-octyl phosphite, di-n-heptyl phosphite, di-isooctyl phosphite, aviation kerosene and TBP were purchased from Shanghai Laish Chemical Co., Ltd.

[0146] Paraformaldehyde, di-n-hexylamine, diisobutylamine, n-butylamine, diisooctylamine, dodecylamine, isooctylamine, dimethylamine, toluene, xylene, p-toluenesulfonic acid, and heptane purchased from Aladdin Reagent Co., Ltd.

[0147] Cyanex923 and 2-methylheptanol were purchased from Shanghai Cyanex Chemical Co., Ltd.

[0148] Feed liquid, washing liquid and stripping agent are self-made in the laboratory.

[0149] Other reagents (such as acids, etc.) are commercially available analytical reag...

preparation example 1

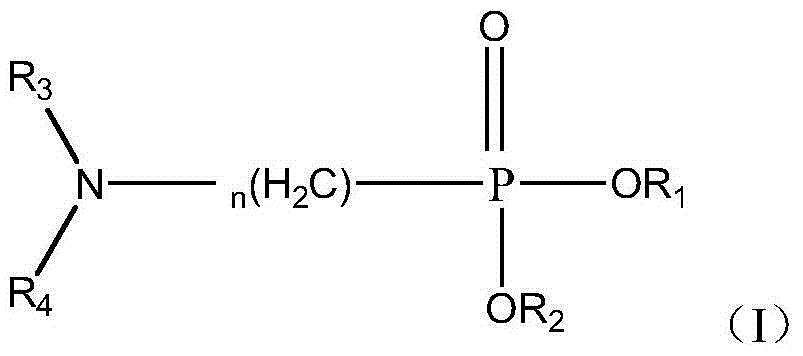

[0152] Preparation Example 1: Preparation of (N,N-dihexylamino)methylphosphonic acid bis(2-ethylhexyl)ester

[0153]

[0154] In a three-necked flask equipped with a mechanical stirrer, a water separator, and a condensation reflux device, add diethylhexyl phosphite (1mol), paraformaldehyde (M=30, 1.05mol), di-n-hexylamine (1.05mol) , toluene (700ml) and p-toluenesulfonic acid (2g), heated to reflux at 130°C, and the water generated by the reaction was separated. When anhydrous is produced, react for another 2 hours. 10 g of potassium carbonate was added to the reaction mixture, and heating to reflux was continued for 15 min. The reaction mixture was filtered to remove excess potassium carbonate in the reaction, washed three times with distilled water, and the toluene was removed by rotary evaporation to obtain the target product.

[0155] 1 HNMR (400MHz, CDCl 3 ,ppm): δ1.74-0.86[m,(CH 3 ) 6 ,(CH 2 ) 16 ,(CH) 2 ],2.63[m,(CH 2 )],2.95[t,CH 2 , J=8Hz], 3.96[m, (CH ...

preparation example 2

[0156] Preparation Example 2: Preparation of Dioctyl (N,N-Diisobutylamino)methylphosphonate

[0157]

[0158] Except that di-n-octyl phosphite was used to replace diethylhexyl phosphite and diisobutylamine was used to replace di-n-hexylamine, the target product was prepared by the same process as in Preparation Example 1.

[0159] 1 HNMR (400MHz, CDCl 3 ,ppm): δ1.71-0.89[m,(CH 3 ) 6 ,(CH 2 ) 12 ],2.05[m,(CH) 2 ],2.31[m,(CH 2 ) 2 ],2.95[m,(CH 2 )],4.02[m,(CH 2 ) 2 ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com