Aspergillus niger genetic engineering bacterium with inactivated calcium ion channel CchA gene and construction method and application thereof

A technology of calcium ion channel and genetically engineered bacteria, applied in the field of genetically engineered bacteria of Aspergillus niger and its construction, can solve the problems of low citric acid yield and long fermentation period, shorten the fermentation period, alleviate the phenomenon of clumping, and improve the yield and sugar The effect of conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

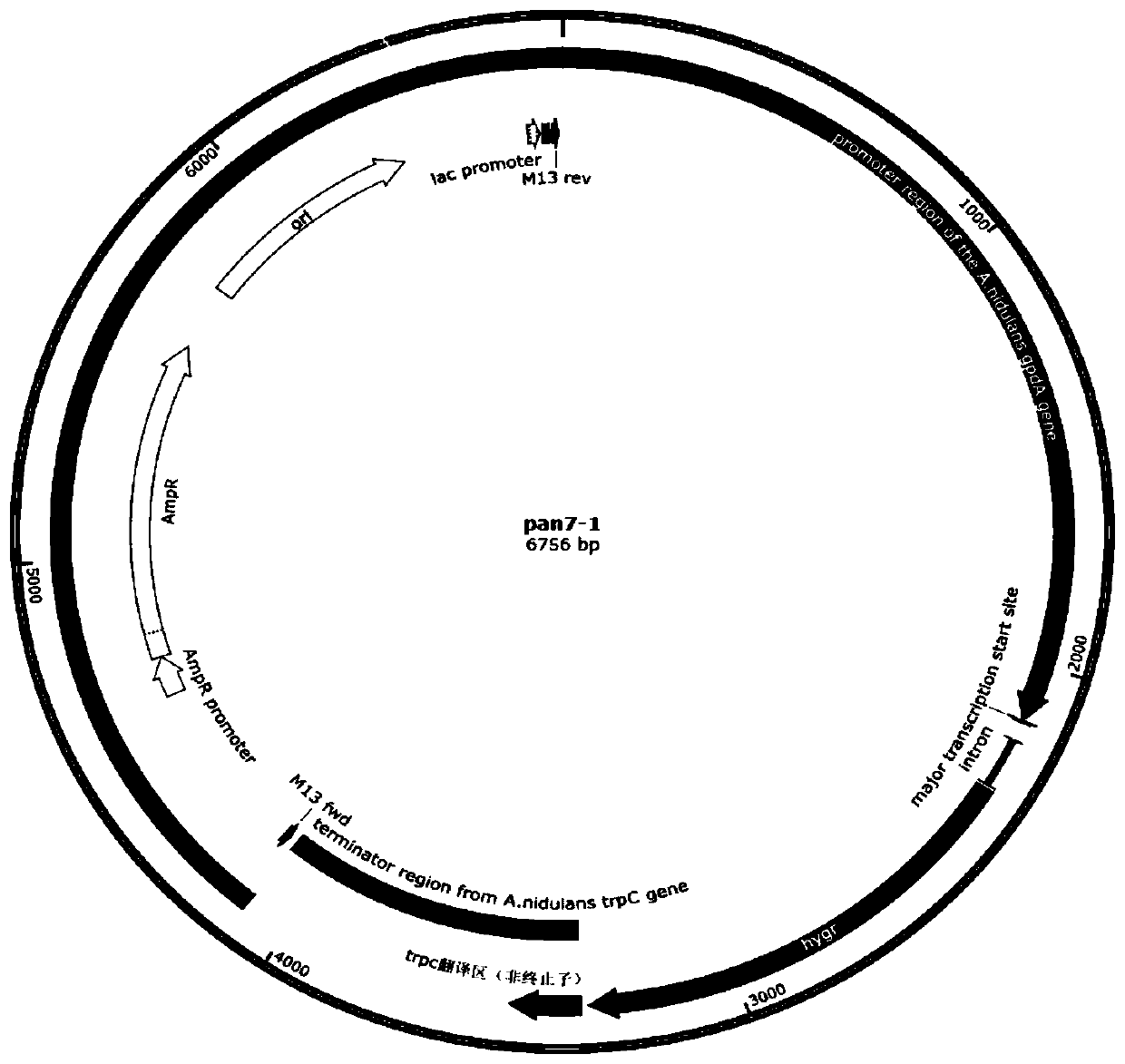

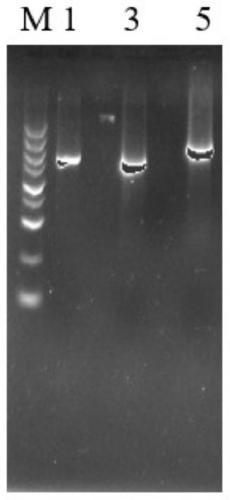

[0044] Example 1: Construction of Aspergillus niger calcium ion channel cchA gene knockout bacteria.

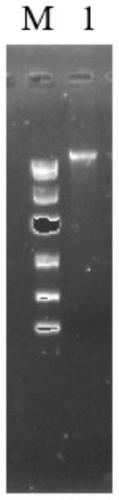

[0045] (1) Extraction of the original Aspergillus niger genome

[0046] Use the takara company's plant genome extraction kit (takara minibest plant genomicDNA extraction kit), and the specific precautions are as follows:

[0047]1. Inoculate 1 mL of the scraped Aspergillus niger spore liquid into 50 mL of DP medium, and incubate at 35°C, 250 r / min for 15 hours;

[0048] 2. Centrifuge at 5000r / min for 5min to collect mycelial balls, wash them twice with normal saline, grind the collected mycelial balls with liquid nitrogen for 3 times, weigh 100mg of the ground powder and add it to Buffer HS II with 500uL added in advance Mix well in the tube tube, then add 10uL of RNase A, shake and mix well, and put in a water bath at 56°C for 10 minutes.

[0049] 3. Add 62.5uL Buffer KAC to step 2 and mix well. Place on ice for 5 minutes, and centrifuge at 12000 rpm for 5 minutes. Take ...

Embodiment 2

[0076] Embodiment 2: crystal violet dyeing experiment

[0077] Inoculate the original Aspergillus niger (Aspergillus Niger 831) and the genetically engineered bacteria on the PDA plate respectively, and when the spores are overgrown, add 3mL of spore scraping buffer to the plate, scrape off the spores with a coating rod, and transfer them to a sterilized 5mL centrifuge In the tube, dilute to 2 mL with spore scraping buffer to obtain spore liquid. Quantify with a hemocytometer and dilute to 10 6 cells / mL, then continue to dilute to 10 5 , 10 4 .

[0078] Add 1ml of synthetic medium in advance to the 24-well plate, and then inoculate 2uL of different concentrations of spore liquid into the medium. Cultivate statically at 35°C for 36 hours to allow Aspergillus niger to form a film at the bottom of the orifice plate. Afterwards, the culture medium was discarded, washed twice with PBS, and stained with 0.1% crystal violet for 15 minutes. Afterwards, the crystal violet was dis...

Embodiment 3

[0082] Embodiment 3: Immobilized fermentation experiment of genetically engineered bacteria.

[0083] 1. Preparation of Porous Fibrous Material Immobilization Medium

[0084] Soak the porous fiber material (activated carbon fiber) in 1M sodium hydroxide for 1 hour, wash it with pure water, then soak it in 1M hydrochloric acid for 1 hour, then rinse it with pure water until the pH is neutral, and then put it in an oven at 65°C for drying Dry to constant weight. Cut into vectors of the same size.

[0085] 2. Preparation of Fermentation Medium

[0086] Weigh 200 / L-300g / L cassava flour and 200g / L-300g / L corn flour and gelatinize in a water bath at 75°C. When the cassava flour and corn flour liquid reach 65°C, add 1-2mL Liquefaction enzyme, liquefy for 40 minutes, then heat the water bath to 95°C, when the cassava flour and corn flour liquid reach 85°C, add 1-2mL of liquefaction enzyme, liquefy for 40min, until the iodine solution does not turn blue, filter the cassava flour sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com