Radiative reduction and curing method of liquid polycarbosilane

A polycarbosilane, liquid technology, applied in the field of polymers, can solve the problems of incomplete hydrogenation and reduction of liquid polycarbosilane, reduce the ceramicization rate of liquid polycarbosilane, and no methyl chloride reduction treatment, etc., to achieve easy industrialization Production, high reproducibility, avoidance of altered effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, in a water-free and oxygen-free glove box with an argon atmosphere, pipette 3ml of liquid polycarbosilane into a petri dish with a diameter of 60mm. The liquid polycarbosilane used is prepared by Grignard coupling-hydrogenation reduction method , the molecular chain contains chloromethyl groups, and the molar ratio of chlorine atoms to carbon atoms is 0.06:1. After the petri dish filled with liquid polycarbosilane is packaged in a PE bag, it is irradiated with high-energy electron beams in the air, and the radiation dose rate is 30kGy / circle, the radiation dose is 240-600kGy. After irradiation, put the sample in a constant temperature box at -20-60°C and let it stand for 1-72 hours to obtain solid polycarbosilane with completely reduced methyl chloride.

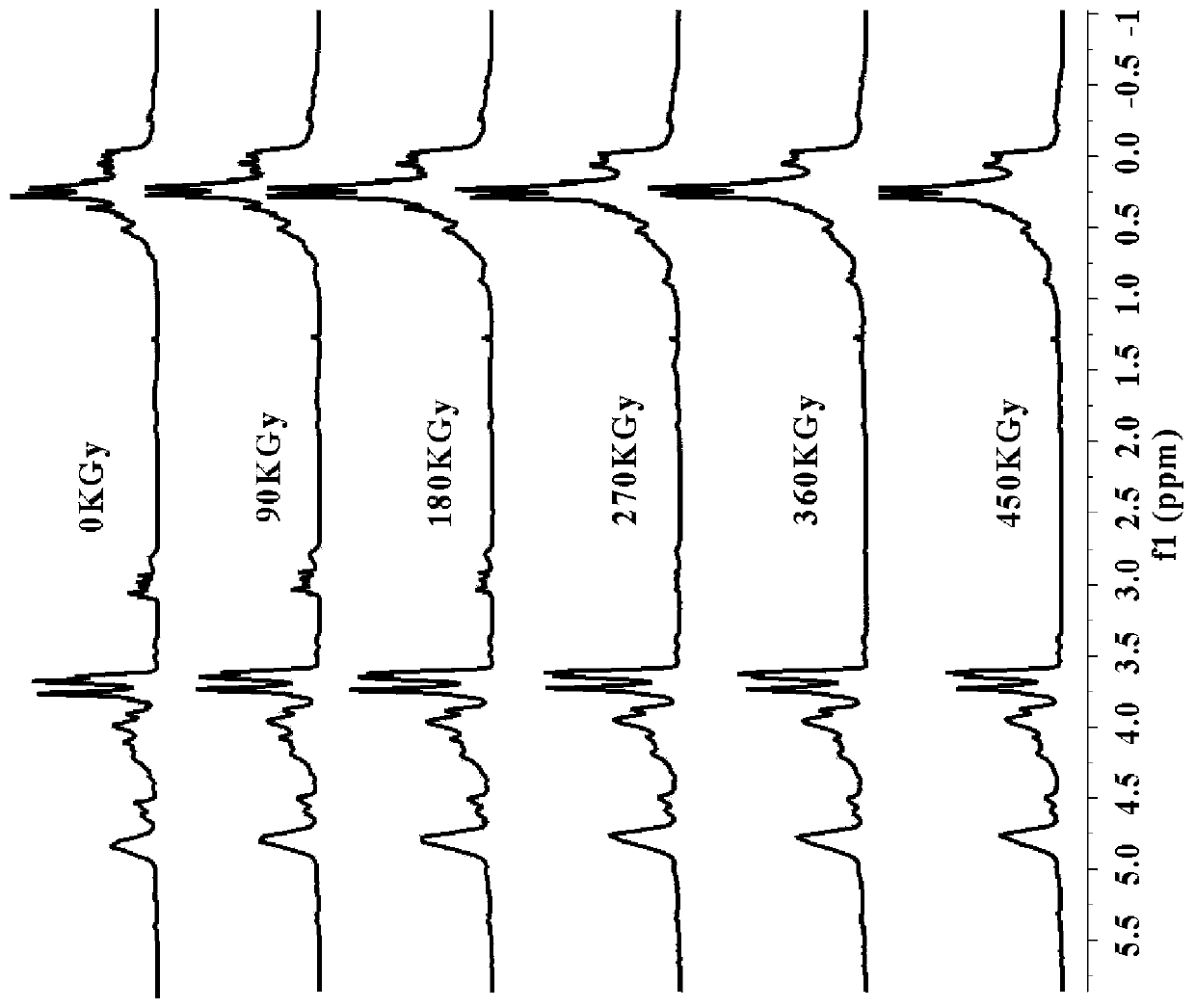

[0032] attached figure 1 It is the H NMR spectrum of liquid polycarbosilane at different radiation doses, as shown in the attached figure 1 It can be seen that with the gradual increase of the ra...

Embodiment 2

[0036] At room temperature, in a water-free and oxygen-free glove box with an argon atmosphere, pipette 3ml of liquid polycarbosilane into a petri dish with a diameter of 60mm. The liquid polycarbosilane used is prepared by Grignard coupling-hydrogenation reduction method , the molecular chain contains chloromethyl groups, and the molar ratio of chlorine atoms to carbon atoms is 0.08:1. After the petri dish filled with liquid polycarbosilane is packaged in PE bags, high-energy electron beams are irradiated in the air, and the radiation dose rate is 30kGy / circle, the radiation dose is 180-360kGy. After irradiation, place the sample in a constant temperature box at -20-60°C and let it stand for 1-72 hours to obtain solid polycarbosilane in which methyl chloride has been incompletely reduced.

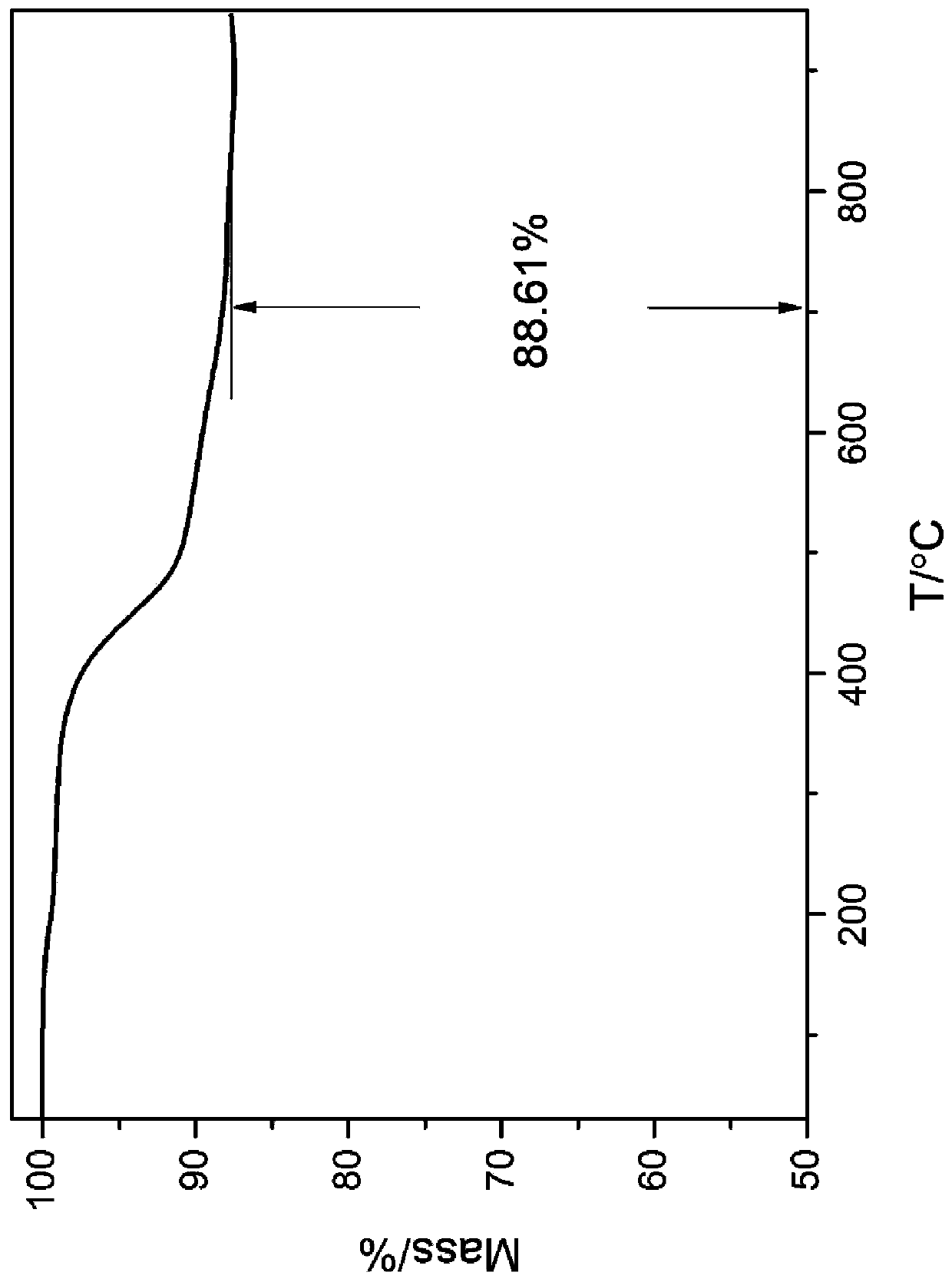

[0037] The polycarbosilane obtained after radiation curing is placed in a corundum crucible, and under the protection of argon, is calcined in a high-temperature tube furnace to 1100°C res...

Embodiment 3

[0039] At room temperature, in the air, use a pipette gun to pipette 3ml of liquid polycarbosilane into a petri dish with a diameter of 60mm. The liquid polycarbosilane used is prepared by Grignard coupling-hydrogenation reduction method. The molecular chain contains chloromethyl, and The molar ratio of chlorine to carbon is 0.03:1. After covering the petri dish filled with liquid polycarbosilane with PE plastic wrap, high-energy electron beams are used to irradiate in the air. The radiation dose rate is 30kGy / circle, and the radiation dose is 240-300kGy. After irradiation, put the sample in a thermostat at -20-60°C and let it stand for 1-72 hours to obtain a solid polycarbosilane in which methyl chloride is completely reduced and oxygen participates in curing.

[0040] The polycarbosilane obtained after radiation curing is placed in a corundum crucible, and under the protection of argon, is calcined in a high-temperature tube furnace to 1300°C respectively to obtain SiC powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com