A kind of high-purity graphite crucible and high-quality silicon carbide single crystal preparation method

A technology of high-quality silicon carbide and high-purity graphite, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems affecting the quality of silicon carbide single crystals, achieve large-scale application prospects, reduce production, reduce The effect of defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

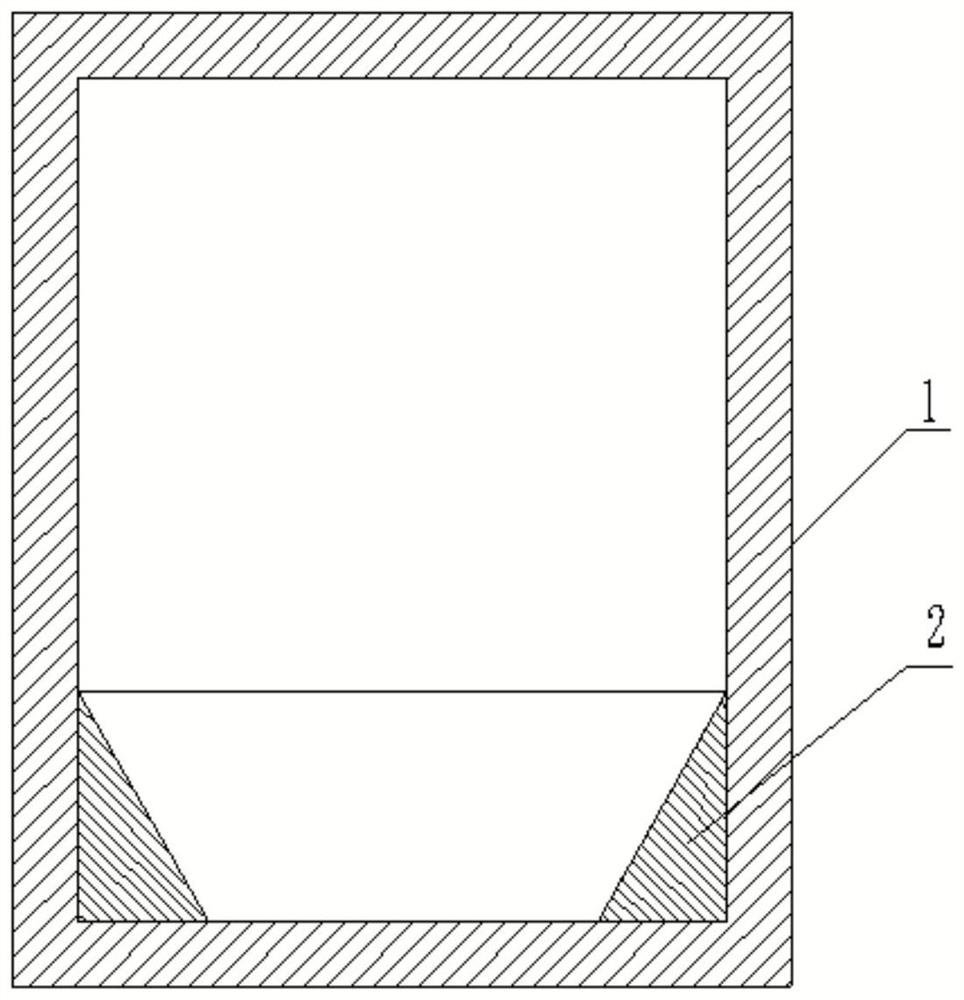

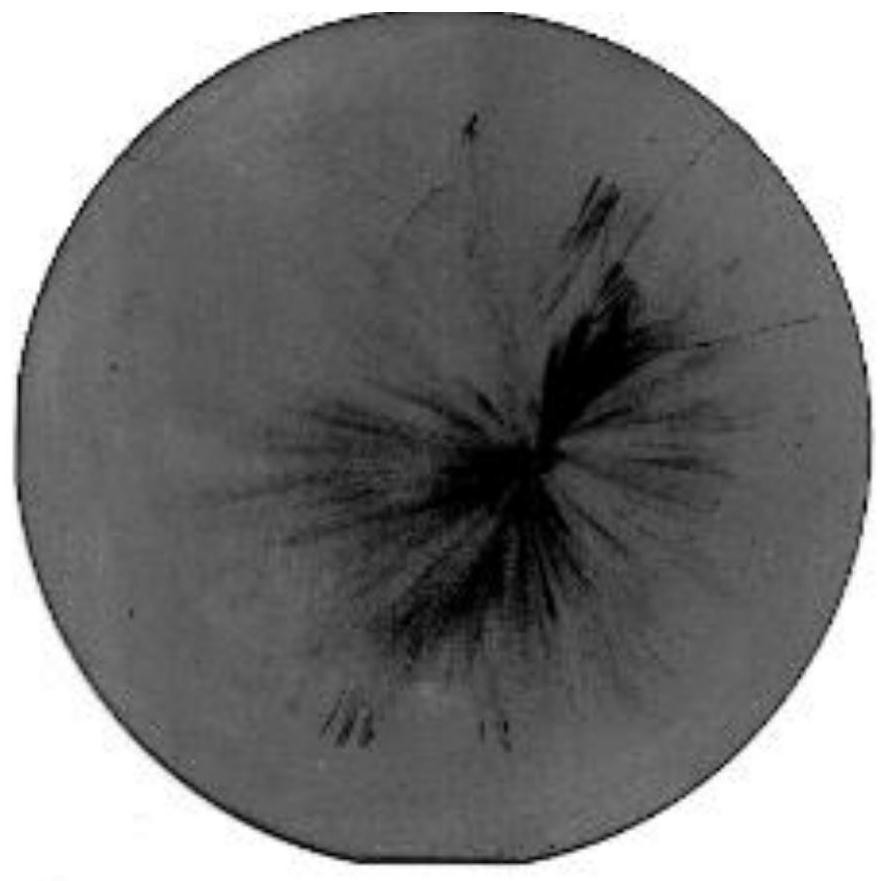

Image

Examples

Embodiment 1

[0035] Powder preparation:

[0036] Weigh 88.2g of silicon micropowder, 34.56g of carbon powder and 2.20g of polyimide into 500L of deionized water, then put them into a ball mill tank, grind at 60rpm for 2h, and spray dry the obtained slurry. The outlet temperature is 95°C, and the obtained dry powder is sintered once. The sintering atmosphere is argon atmosphere, the sintering temperature is 1900°C, and the sintering time is 2h. The powder is sintered in an oxidizing atmosphere for the purpose of removing excess adhesion. agent, and the product can be initially formed. The initial product to be obtained with 4.3 g of Y 2 o 3 , use a V-type mixer to mix for 3 hours, and then sinter for the second time in an atmosphere with a hydrogen:argon volume ratio of 1:7. The sintering temperature is 2300 ° C, and the sintering time is 3 hours. The sintered powder is post-treated process to form silicon carbide powder products.

[0037] Loading:

[0038] The high-purity graphite cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com