Monocrystalline silicon solar cell texturing additive and application thereof

A solar cell and monocrystalline silicon technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of processes such as diffusion, screen printing influence, pyramid enlargement, unevenness, etc., to avoid white spots, The effect of increasing the production capacity and making the suede surface small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

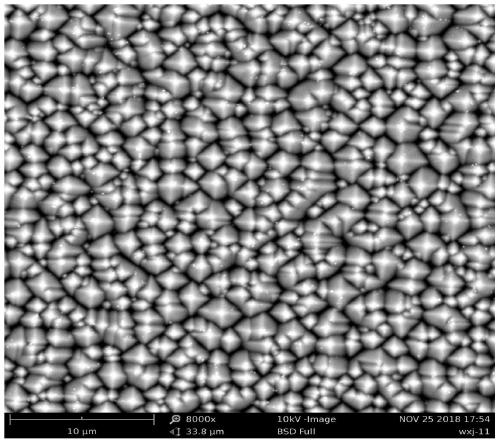

[0043] Embodiment 1-6: the application of a monocrystalline silicon solar cell texturing additive, comprising the following steps:

[0044] Add the monocrystalline silicon solar cell texturing additive into the monocrystalline texturing tank with the pre-prepared texturing liquid, and control the temperature at 82°C. >The P-type B-doped monocrystalline silicon wafer on the crystal surface is immersed in the single crystal texturing tank for reaction, and the texturing time is controlled at 400s;

[0045] Wherein the texturing liquid includes 1.6% sodium hydroxide, the mass ratio of the monocrystalline silicon solar cell texturing additive to the texturing liquid is 0.01:1, each component of the monocrystalline silicon solar cell texturing additive and its corresponding mass The percentages are shown in Table 1.

[0046] Each component and parts by weight thereof in table 1 embodiment 1-6

[0047]

Embodiment 7

[0048] Embodiment 7: The application of a monocrystalline silicon solar cell texturing additive, the difference from Example 1 is that the monocrystalline silicon solar cell texturing additive includes the following components in mass percentage:

[0049] Sodium hydroxide: 0.05%;

[0050] Methyl glucose polyoxyethylene ether: 0.5%;

[0051] Glucose: 0.3%;

[0052] Polyacrylamide: 0.01%;

[0053] Lactic acid: 0.1%;

[0054] Potassium dodecylsulfonate: 0.1%;

[0055] Silicone surfactant: 0.1%;

[0056] Sodium silicate: 0.01%;

[0057] Deionized water: 98.74%.

Embodiment 8

[0058] Embodiment 8: The application of a monocrystalline silicon solar cell texturing additive, the difference from Example 1 is that the monocrystalline silicon solar cell texturing additive includes the following components in mass percentage:

[0059] Sodium hydroxide: 0.05%;

[0060] Methyl glucose polyoxyethylene ether: 0.5%;

[0061] Glucose: 0.3%;

[0062] Polyacrylamide: 0.01%;

[0063] Lactic acid: 0.1%;

[0064] Potassium dodecylsulfonate: 0.1%;

[0065] Silicone surfactant: 0.1%;

[0066] Sodium silicate: 2%;

[0067] Deionized water: 96.84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com