A kind of electric composite insulator repair adhesive and preparation method thereof

A composite insulator, repair glue technology, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., can solve the problems of no flame retardancy, low flame retardancy, repair process operation, etc. The effect of concentrated field strength, consistent hardness and elasticity, and strong overall adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

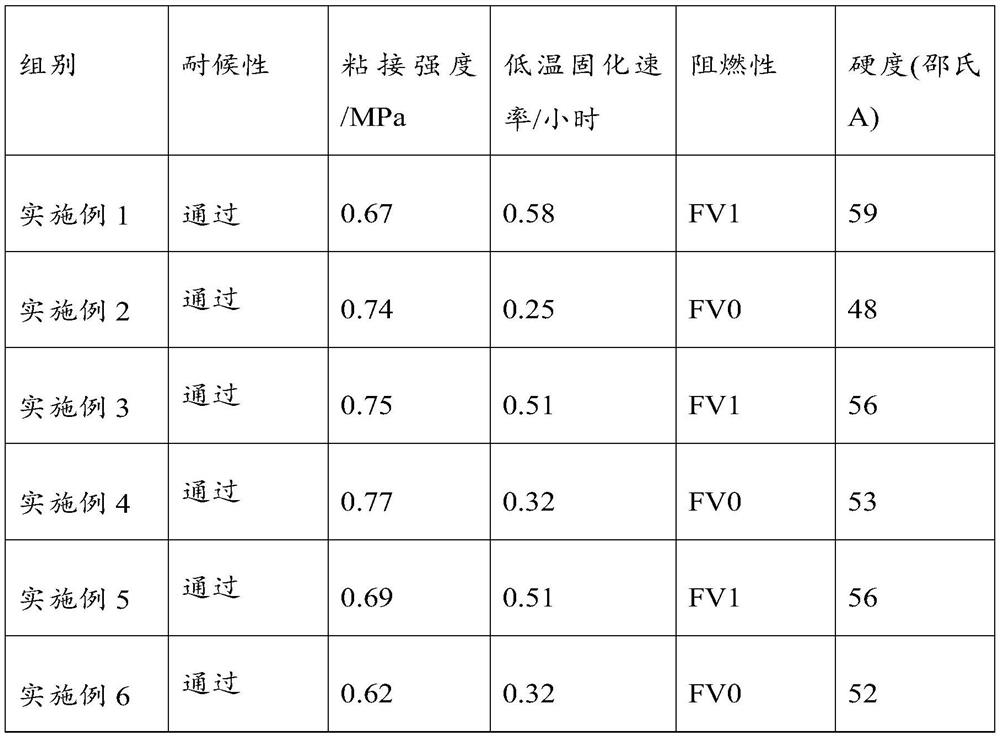

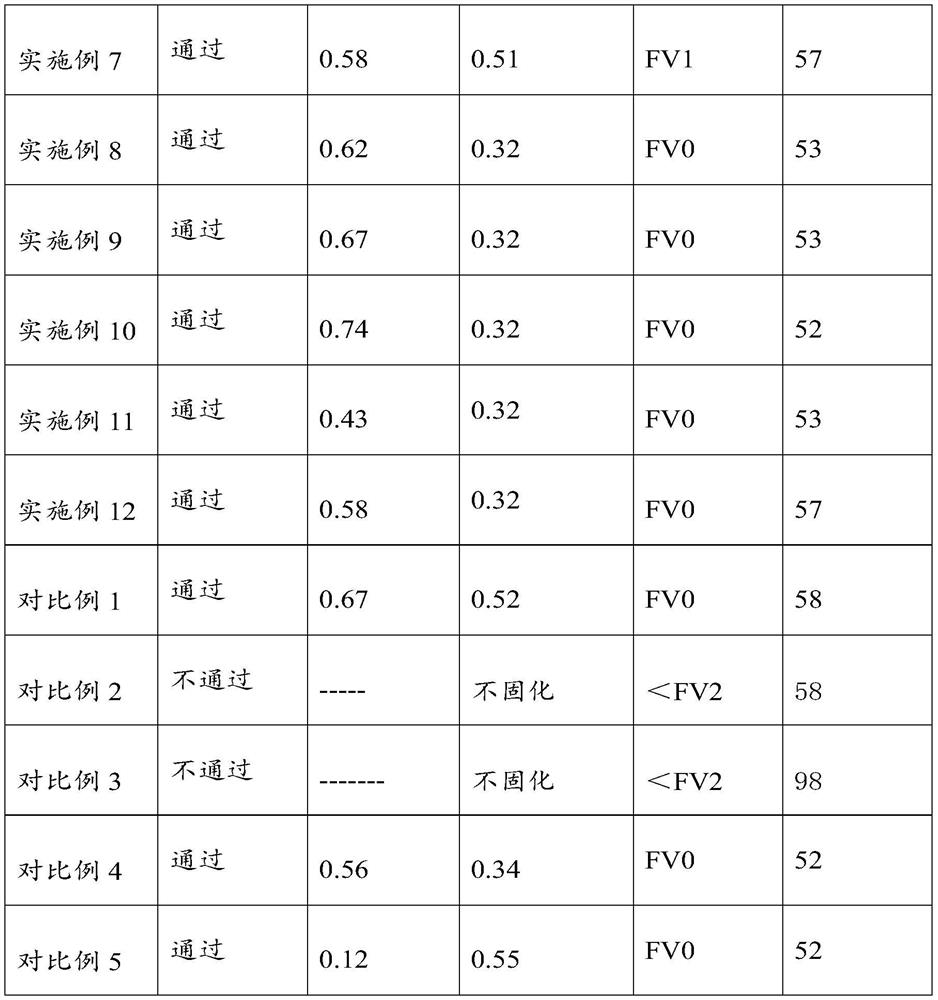

Examples

Embodiment 1

[0037] This embodiment provides a kind of power composite insulator repair glue, its raw materials are counted in parts by weight, including: 80 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 5000mPa.s, silane-modified polyether with a viscosity of 5000mPa.s 5 parts of prepolymer, the specific surface area is 400cm 2 2 parts per g of white carbon black, 40 parts of flame retardant, 5 parts of crosslinking agent, 10 parts of coupling agent, and 0.1 part of catalyst. Among them, the flame retardant includes 15 parts of aluminum hydroxide, 10 parts of magnesium hydroxide, 5 parts of zinc borate, and 10 parts of hydrotalcite; the crosslinking agent is methyl tributylketoximosilane; the coupling agent includes γ-aminopropyl 10 parts of triethoxysilane, 5 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane and 10 parts of γ-aminoethylaminopropyltrimethoxysilane; the catalyst is dilauric acid Dibutyltin.

[0038] This embodiment also provides a preparation metho...

Embodiment 2

[0044] This embodiment provides a kind of electric composite insulator repair glue, its raw materials are counted in parts by weight, including: 200 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 80000mPa.s, and silane-modified polyether with a viscosity of 50000mPa.s 40 parts of prepolymer, the specific surface area is 100cm 2 / g of 30 parts of white carbon black, 280 parts of flame retardant, 30 parts of crosslinking agent, 50 parts of coupling agent, and 3 parts of catalyst. Among them, the flame retardant includes 180 parts of aluminum hydroxide, 35 parts of quartz powder, 40 parts of ammonium polyphosphate, 15 parts of aluminum oxide, and 10 parts of zinc borate; 2 parts of ketoxime silane, 0.2 part of methyltriacetone oximino silane; coupling agent includes 35 parts of γ-aminopropyltriethoxysilane and 15 parts of γ-aminoethylaminopropyltrimethoxysilane; catalyst It is 3 parts of dibutyltin diacetate.

[0045] This embodiment also provides a prepa...

Embodiment 3

[0051] This embodiment provides a kind of power composite insulator repair glue, its raw materials are counted by weight, including: 80 parts of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10000mPa.s, and silane-modified polyether with a viscosity of 8000mPa.s 10 parts of prepolymer, the specific surface area is 400cm 2 / g of white carbon black 10 parts, flame retardant 50 parts, crosslinking agent 8 parts, coupling agent 20 parts, catalyst 0.2 parts. Among them, the flame retardant includes 40 parts of hydrotalcite, 7 parts of decabromodiphenyl ether and 3 parts of antimony trioxide; 14 parts of propoxy)propyltrimethoxysilane and 6 parts of γ-aminoethylaminopropyltrimethoxysilane; the catalyst is chelated tin.

[0052] This embodiment also provides a preparation method of electric composite insulator repair glue, which uses the above formula as a raw material, comprising the following steps:

[0053] (1) Stir the coupling agent evenly and distill at 120° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com