Surface treatment metal, treatment method thereof, metal resin composite body and preparing method thereof

A treatment method and surface treatment technology, applied in the direction of coating, etc., can solve the problems of insufficient depth of nano-holes, low bonding force of injection molding products, small nano-holes, etc., to solve the problem of insufficient bonding force, improve the tensile strength at break Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Pretreatment: Cut a commercially available 1mm thick titanium plate into rectangular pieces of 450mm*150mm, put it into acetone solution, ultrasonically clean it for 30 minutes, and rinse it with deionized water to obtain a pretreated titanium plate.

[0058] Metal Surface Treatment:

[0059] 1. Put the pretreated titanium sheet in the polishing solution and polish it for 5 minutes. The polishing solution is a mixed acid solution of nitric acid and hydrofluoric acid;

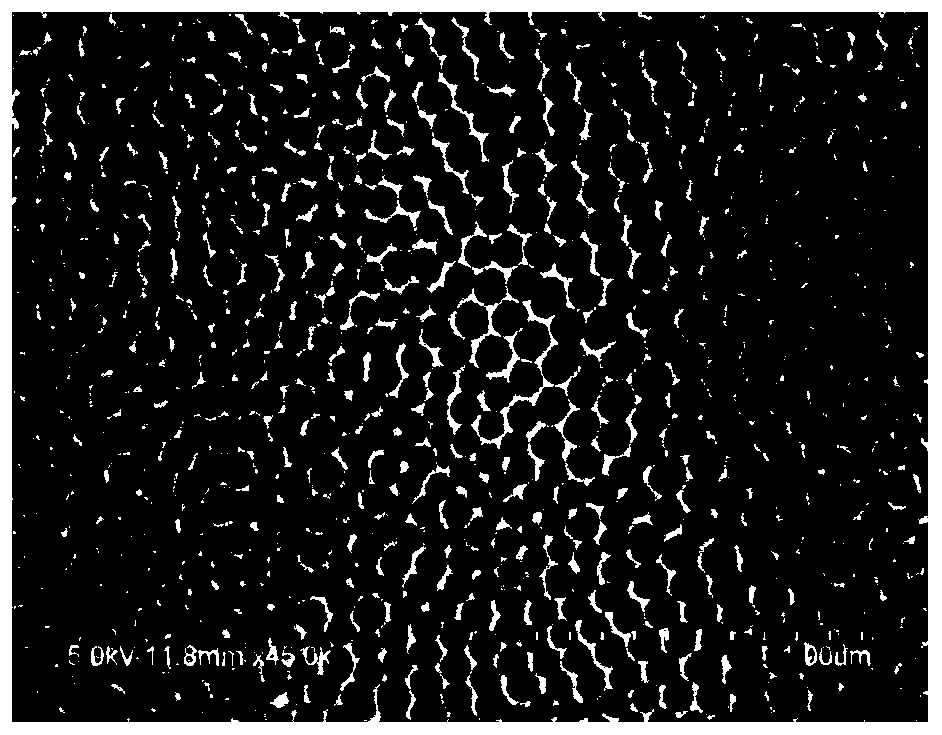

[0060] 2. Anodize the polished titanium sheet at 40V for 15min in 0.30wt% ammonium fluoride in ethylene glycol solution. After testing, there is an oxide layer on the metal surface, such as Figure 1-2 , figure 1 It is the electron microscope picture of the front surface of the oxide layer. It can be seen that the inner diameter of the nanotube is 100nm. figure 2 It is the cross-sectional electron microscope picture of the oxide layer. It can be seen that the tube length is greater than 2um, and the ox...

Embodiment 2

[0067] Pretreatment: Cut a commercially available 1mm thick titanium plate into rectangular pieces of 450mm*150mm, put it into acetone solution, ultrasonically clean it for 30 minutes, and rinse it with deionized water to obtain a pretreated titanium plate.

[0068] Metal Surface Treatment:

[0069] 1. Put the pretreated titanium sheet in the polishing solution and polish it for 5 minutes. The polishing solution is a mixed acid solution of nitric acid and hydrofluoric acid;

[0070] 2. Anodize the polished titanium sheet in 1.00wt% ammonium fluoride ethylene glycol solution at 20V for 15 minutes. After detecting that there is an oxide layer on the metal surface, the oxide layer is removed by ultrasonication;

[0071] 3. Anodize the pre-oxidized titanium sheet in 0.50wt% hydrofluoric acid solution at 15V for 40min, and ultrasonically remove unstable deposits and adsorbates on the surface;

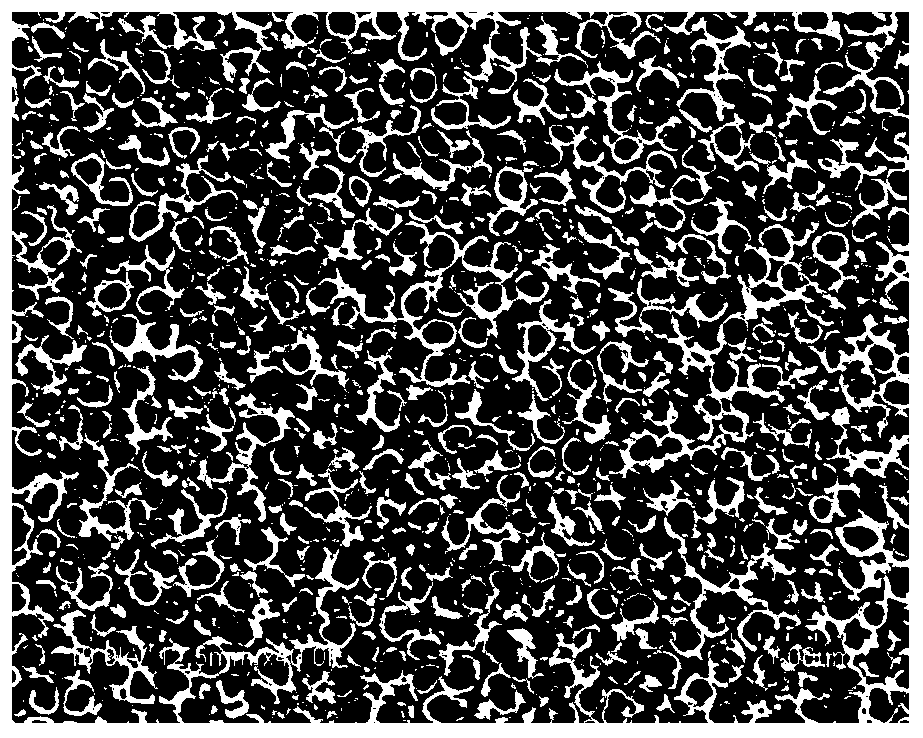

[0072] After detection, there are nanotube structures on the surface of the titanium su...

Embodiment 3

[0075] Pretreatment: Cut a commercially available 1mm thick titanium plate into rectangular pieces of 450mm*150mm, put it into acetone solution, ultrasonically clean it for 30 minutes, and rinse it with deionized water to obtain a pretreated titanium plate.

[0076] Metal Surface Treatment:

[0077] 1. Put the pretreated titanium sheet in the polishing solution and polish it for 5 minutes. The polishing solution is a mixed acid solution of nitric acid and hydrofluoric acid;

[0078] 2. Anodize the polished titanium sheet in 0.65wt% ammonium fluoride ethylene glycol solution at 30V for 15 minutes. After detecting that there is an oxide layer on the metal surface, the oxide layer is removed by ultrasonic;

[0079] 3. Anodize the pre-oxidized titanium sheet in 0.50wt% hydrofluoric acid solution at 17V for 40min, and ultrasonically remove unstable deposits and adsorbates on the surface;

[0080] After detection, there are nanotube structures on the surface of the titanium substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com