Method for preparing ultra-thin metal grid flexible transparent electrode by ink-jet printing combining electroless plating process

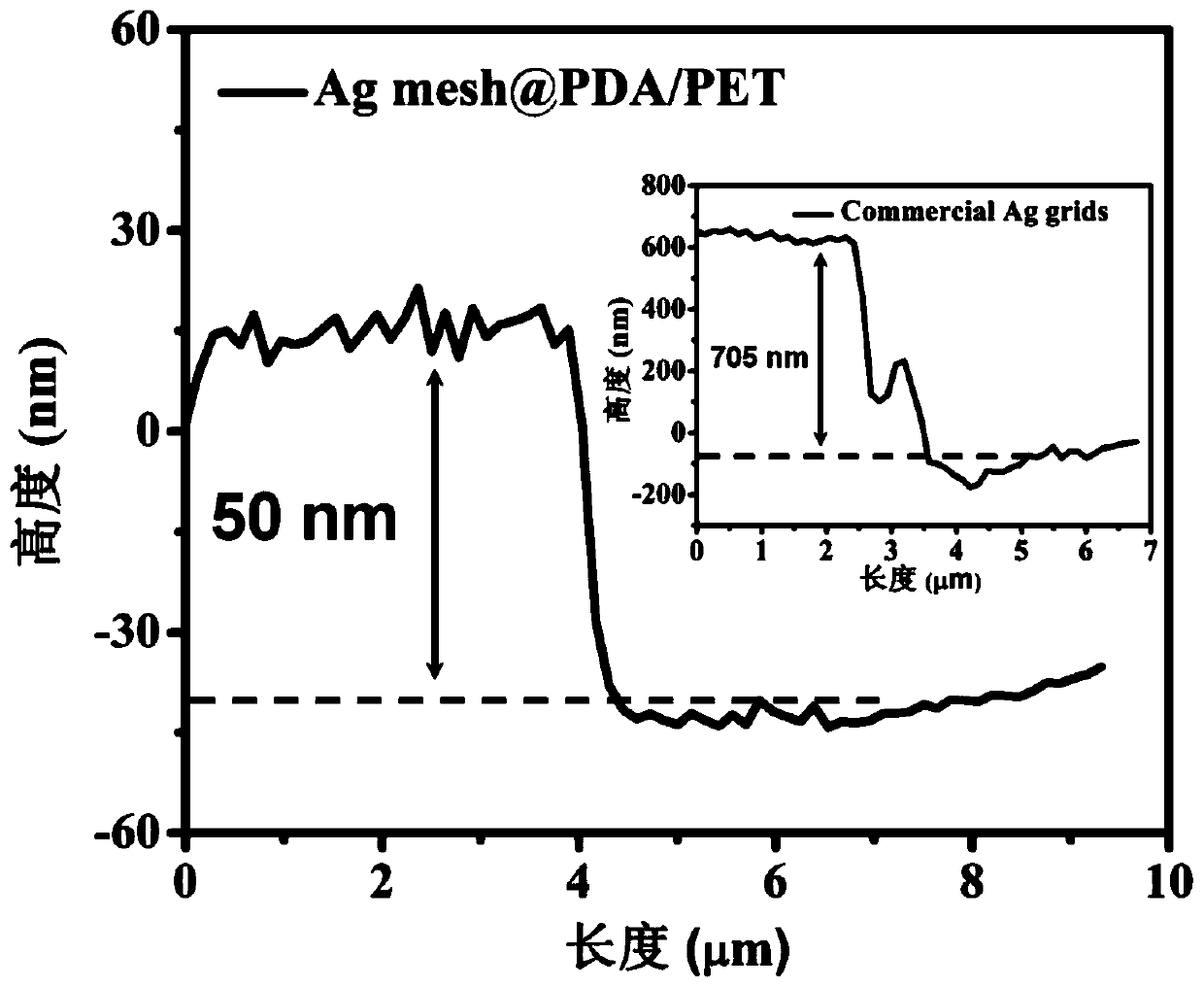

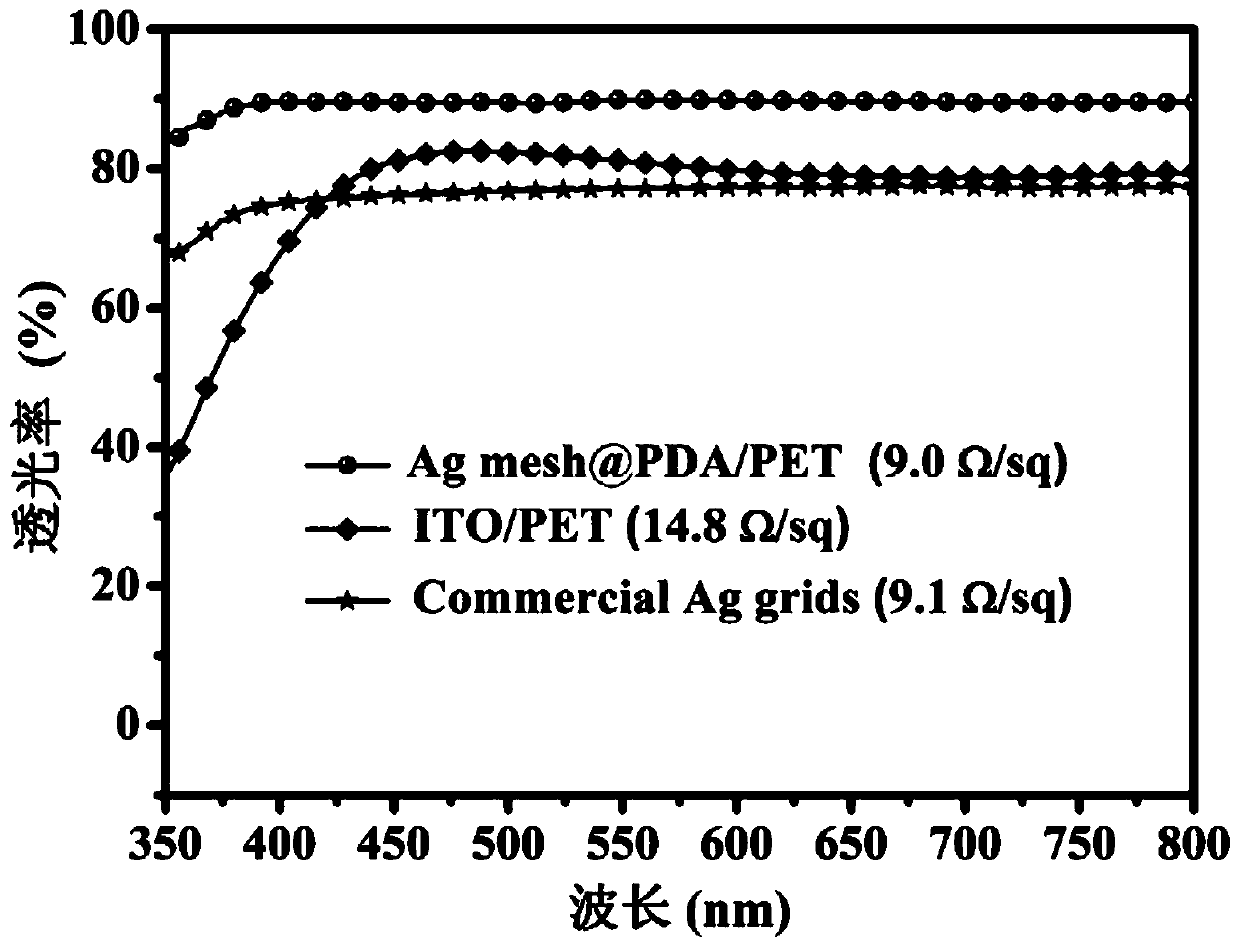

An ultra-thin metal and inkjet printing technology, which is applied in the direction of copying/marking method, printing post-processing, metal material coating process, etc., can solve the problem of increasing the complexity of the electrode material processing process and the high annealing temperature of the metal mesh transparent electrode , metal grid transparent electrode thickness and other issues, to achieve excellent transparent conductivity and uniform morphology, low cost, good oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]

[0037] a) Weigh 0.09g of tris(hydroxymethyl)methylamine hydrochloride and 0.17g of tris(hydroxymethyl)aminomethane and dissolve in 200mL of deionized water, add 0.4g of dopamine (DA) to dissolve and form a polydopamine (PDA) solution;

[0038] b) Immediately immerse the oxygen plasma-treated substrate (polyethylene terephthalate, PET) in the buffer solution a) and react for 20 minutes, and place the substrate containing the PDA coating in an oven at 60° C. for 15 minutes;

[0039] c) Weigh 2.5015g of polystyrene (PS), stir and dissolve it in 15mL of N,N-dimethylformamide in an oil bath at 60°C, and prepare 15wt% PS ink;

[0040] d) Put PS ink into an inkjet printer, and design a matrix pattern with a line width of 300 μm and a line spacing of 2 mm in the printer programming software, and then perform inkjet printing on a substrate with a PDA coating, and obtain a matrix mask after the ink dries quickly. template pattern;

[0041] e) Add 0.815g of silver nitrate to...

Embodiment 2

[0046]

[0047] a) Weigh 0.09g of tris(hydroxymethyl)methylamine hydrochloride and 0.17g of tris(hydroxymethyl)aminomethane and dissolve in 200mL of deionized water, add 0.4g of dopamine (DA) to dissolve and form a polydopamine (PDA) solution;

[0048] b) Immediately immerse the oxygen plasma-treated substrate (polyethylene terephthalate, PET) in the buffer solution a) and react for 20 minutes, and place the substrate containing the PDA coating in an oven at 60° C. for 15 minutes;

[0049] c) Weigh 0.0427g of polymethylmethacrylate (PMMA), stir and dissolve it in 15mL of N,N-dimethylformamide under the condition of 60°C oil bath, and configure it into 0.3wt% PMMA ink;

[0050] d) PMMA ink is loaded into an inkjet printer, and a matrix pattern of 300 μm line width and 2mm line spacing is designed in the printer programming software, and then inkjet printing is carried out on a substrate with a PDA coating, and the matrix mask is obtained after the ink dries quickly. template...

Embodiment 3

[0056]

[0057] a) Weigh 0.09g of tris(hydroxymethyl)methylamine hydrochloride and 0.17g of tris(hydroxymethyl)aminomethane and dissolve in 200mL of deionized water, add 0.4g of dopamine (DA) to dissolve and form a polydopamine (PDA) solution;

[0058] b) Immediately immerse the oxygen plasma-treated substrate (polyethylene terephthalate, PET) in the buffer solution a) and react for 20 minutes, and place the substrate containing the PDA coating in an oven at 60° C. for 15 minutes;

[0059] c) Weigh 0.0712g of polyacrylonitrile (PAN), stir and dissolve it in 15mL of N,N-dimethylformamide in an oil bath at 60°C, and configure it as 0.5wt% PAN ink;

[0060] d) Put PS ink into an inkjet printer, and design a matrix pattern with a line width of 300 μm and a line spacing of 2 mm in the printer programming software, and then perform inkjet printing on a substrate with a PDA coating, and obtain a matrix mask after the ink dries quickly. template pattern;

[0061] e) Add 0.815g of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com