Preparation method and product of in-situ self-generated ceramic phase-reinforced titanium-based composite material

A titanium-based composite material, in-situ self-generation technology, applied in the field of powder metallurgy, can solve the problem of high cost, achieve the effect of reducing process cost, improving operability, and avoiding inert gas environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention discloses a method for preparing an in-situ self-generated ceramic phase-reinforced titanium-based composite material, which comprises the following steps:

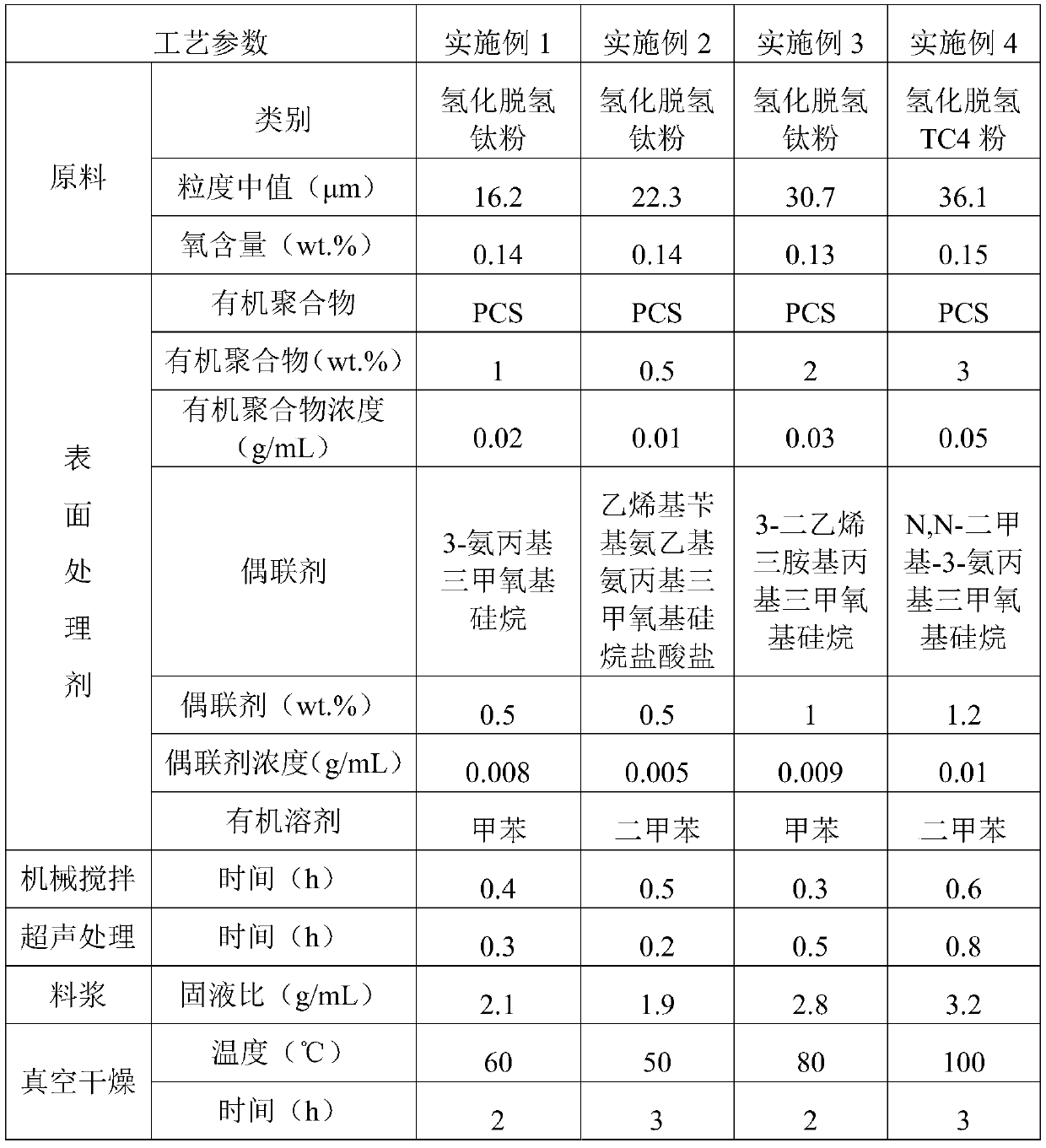

[0037] (1) Preparation of powder surface treatment agent: 3-aminopropyltrimethoxysilane, vinylbenzylaminoethylaminopropyltrimethoxysilane hydrochloride, 3-diethylenetriaminopropyltrimethoxysilane Dimethylsilane or N,N-dimethyl-3-aminopropyltrimethoxysilane is dissolved in xylene or toluene to obtain a solution with a mass volume concentration of 0.002-0.01g / mL, and then polycarbosilane (PCS) is dissolved in In the above solution, a solution with a mass volume concentration of 0.003-0.05 g / mL is obtained.

[0038] (2) Add hydrogenated dehydrogenated titanium powder with a particle size median diameter D50 of 10-40 μm and an oxygen content less than or equal to 0.15wt.% to the powder surface treatment agent in step (1), seal the inert gas, and mechanically stir for 0.2-0.6h , and then ultrasonically tr...

Embodiment 1

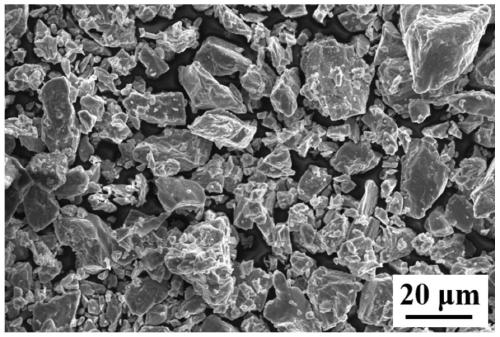

[0045] Using hydrogenated dehydrogenation titanium powder with a median particle size of 16.2 μm and an oxygen content of 0.14wt.% as raw material, the scanning electron microscope morphology photo is as follows figure 1 shown.

[0046] 0.5wt.% of 3-aminopropyltrimethoxysilane was dissolved in toluene organic solvent to prepare a solution with a concentration of 0.008g / mL, and then 1wt.% of polycarbosilane (PCS) was added to the solution, Prepare a mixed solution with a concentration of 0.02g / mL.

[0047] The raw material powder was added to the prepared mixed solution, sealed with high-purity argon protection, magnetically stirred for 0.4 h, and then ultrasonically treated in an ultrasonic cleaner for 0.3 h to prepare a slurry with a solid-to-liquid ratio of 2.1 g / mL.

[0048] Put the prepared slurry into a vacuum oven and dry at 60°C for 2 hours.

[0049] The dried slurry was mixed with 0.8wt.% calcium carbide (CaC 2 ) powders were put into the ball mill jar and filled wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com