Powder surface treating agent, titanium or titanium alloy powder surface treatment method and composite powder

A technology of powder surface treatment and titanium alloy powder, which is applied in the field of powder surface treatment agents and composite powders, can solve the problems of poor activity and high cost, achieve low cost, reduce process cost, and improve operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

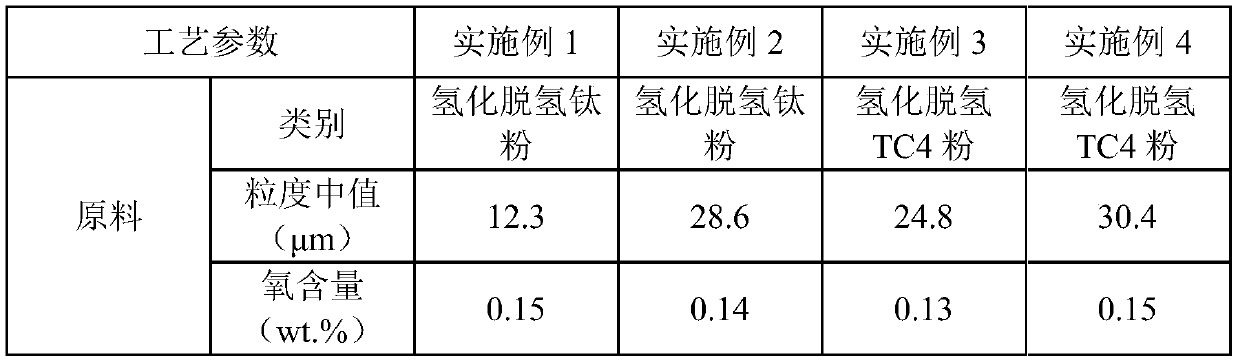

[0035] (1) Preparation of powder surface treatment agent: isopropyl tris(dioctyl pyrophosphate acyloxy) titanate, isopropoxy dioleic acid acyloxy (dioctyl phosphate acyloxy) titanic acid Ester, isopropyl tris(dioctyl phosphate acyloxy) titanate or isopropyl tris(dioctyl pyrophosphoryl) titanate dissolved in xylene or toluene to obtain a mass volume concentration of 0.001-0.004g / mL solution, and then at least one of polystyrene (PS) and ABS plastic is dissolved in the above solution to obtain a solution with a mass volume concentration of 0.005-0.04 g / mL.

[0036] (2) Add hydrogenated dehydrogenated titanium or titanium alloy powder with a median particle size D50 of 10-40μm and an oxygen content of 0.15wt.% or less into the powder surface treatment agent of step (1), seal the inert gas, and mechanically stir 0.1 -0.5h, then ultrasonic treatment in an ultrasonic cleaner for 0.1-0.6h to prepare a slurry with a solid-liquid ratio of 1.2-3.5g / mL.

[0037] (3) Drying the slurry in ste...

Example Embodiment

[0039] Example 1:

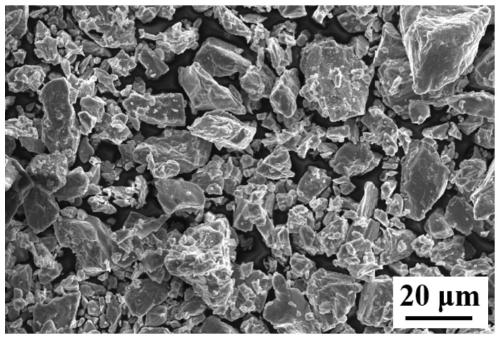

[0040] Using hydrogenated dehydrogenated titanium powder with a median particle size of 12.3μm and an oxygen content of 0.15wt.% as the raw material, the scanning electron microscope morphology photo is figure 1 Shown.

[0041] Dissolve NDZ-201 in xylene organic solvent to prepare a solution with a uniform concentration of 0.003g / mL, and then dissolve PS in the solution to prepare a solution with a uniform concentration of 0.02g / mL.

[0042] Then, the raw material powder is added to the prepared solution, sealed with high-purity inert gas protection, mechanically stirred for 0.5h, and then ultrasonically treated in an ultrasonic cleaner for 0.2h to prepare a slurry with a solid-liquid ratio of 2.6g / mL.

[0043] The prepared slurry was taken out, put into a vacuum drying oven, and dried at 40°C for 1 hour to obtain composite powder.

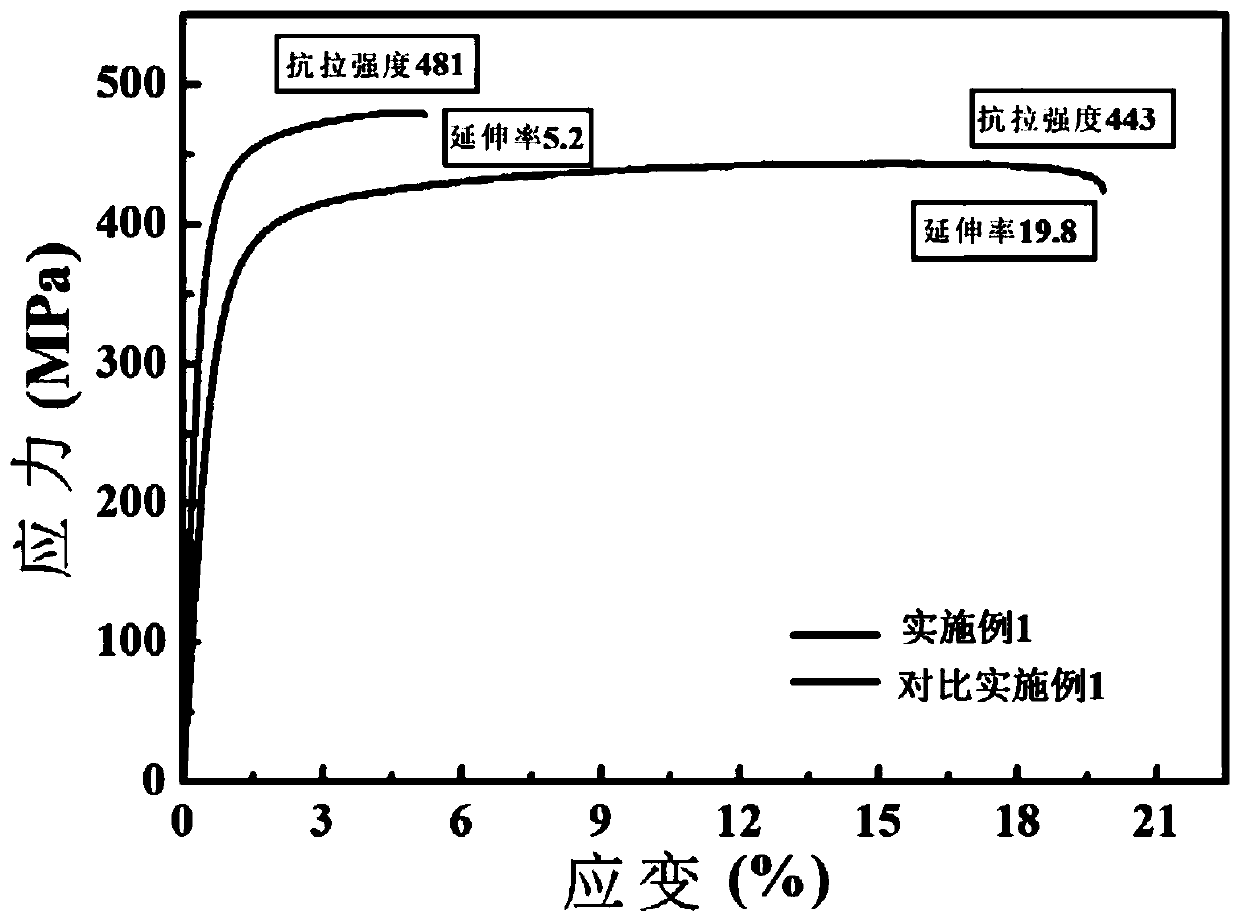

[0044] The prepared composite powder is used in a powder metallurgy process: it is packed into a soft film and cold isostatically press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com