Powder surface treatment agent, titanium or titanium alloy powder injection molding method and product

A technology of powder surface treatment and powder injection molding, which is applied in the field of powder metallurgy, can solve the problems of high cost and difficulty in densification, and achieve the effects of high density, improved operability and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

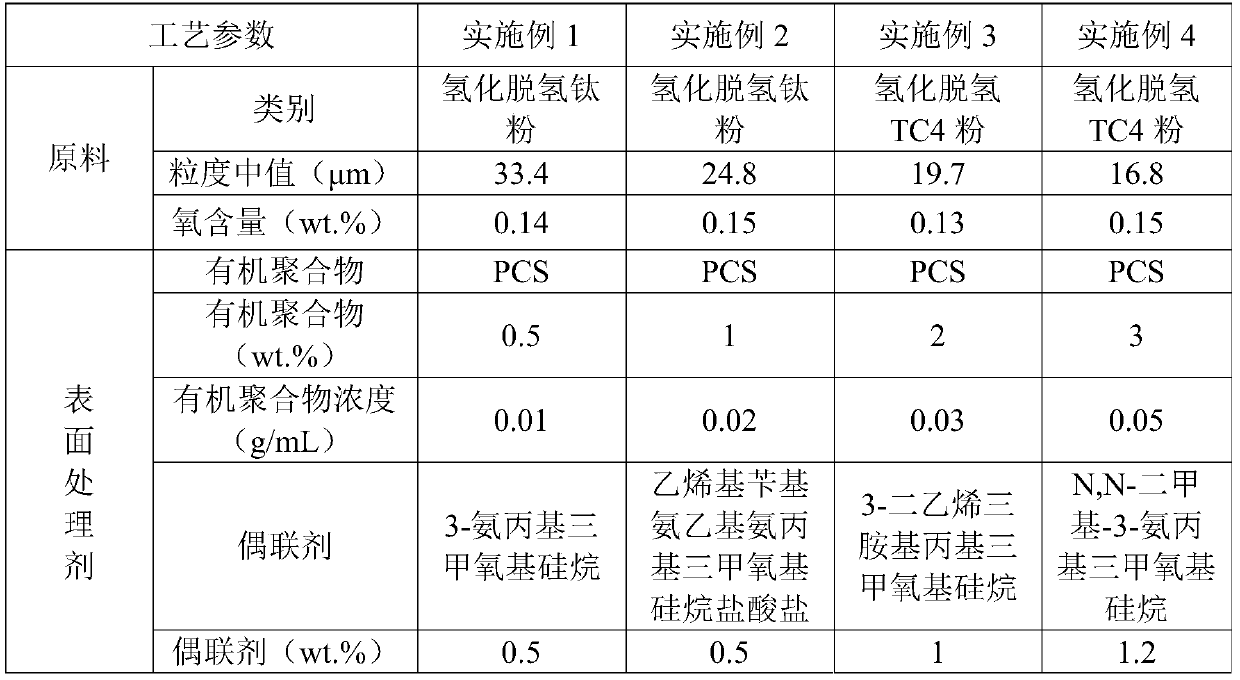

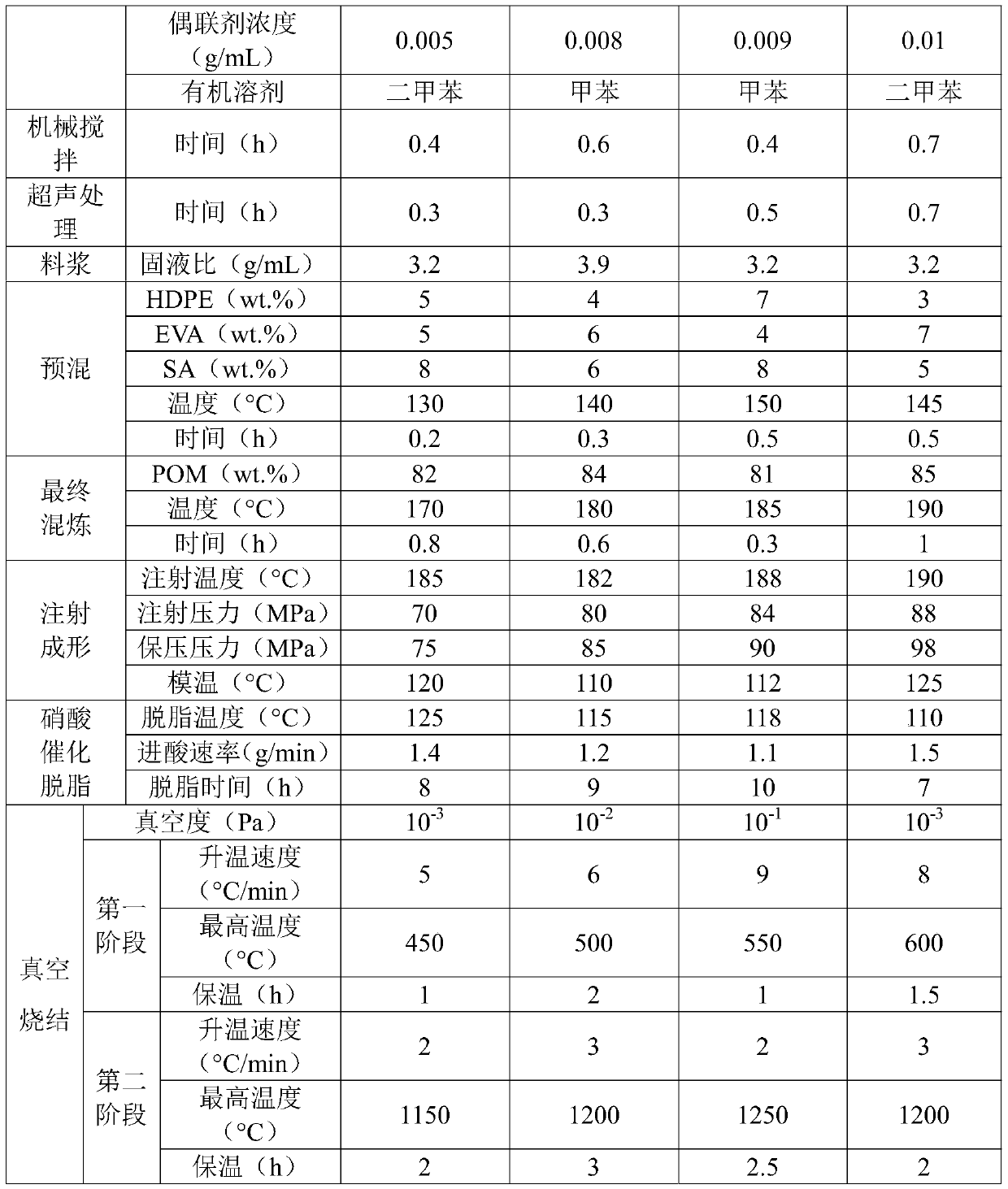

[0035](1) Preparation of powder surface treatment agent: 3-aminopropyltrimethoxysilane, vinylbenzylaminoethylaminopropyltrimethoxysilane hydrochloride, 3-diethylenetriaminopropyltrimethoxysilane Dimethylsilane or N,N-dimethyl-3-aminopropyltrimethoxysilane is dissolved in toluene or xylene to obtain a solution with a mass volume concentration of 0.002-0.01g / mL, and then polycarbosilane (PCS) is dissolved A solution with a mass volume concentration of 0.003-0.05 g / mL is obtained in the above solution.

[0036] (2) Add hydrogenated dehydrogenated titanium or titanium alloy powder with a particle size median diameter D50 of 10-40 μm and an oxygen content less than or equal to 0.15wt.% to the powder surface treatment agent in step (1), seal the inert gas, and mechanically stir for 0.2 -0.9h, and then ultrasonically treated in an ultrasonic cleaner for 0.2-0.8h to prepare a slurry with a solid-to-liquid ratio of 1.2-3.5g / mL.

[0037] (3) Premix the slurry prepared in step (2) with ...

Embodiment 1

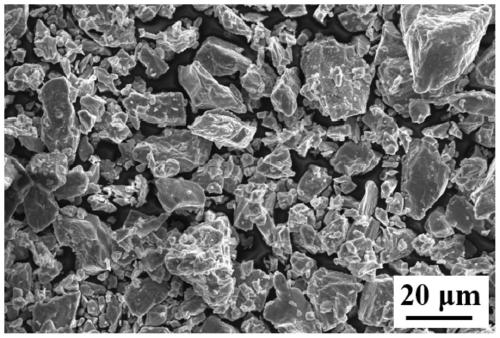

[0044] Using hydrogenated dehydrogenation titanium powder with a median particle size of 33.4 μm and an oxygen content of 0.14wt.% as raw material, the scanning electron microscope morphology photo is as follows figure 1 shown.

[0045] 0.5wt.% of 3-aminopropyltrimethoxysilane was dissolved in xylene organic solvent to prepare a solution with a concentration of 0.005g / mL, and then 0.5wt.% of polycarbosilane (PCS) was dissolved in the solution , prepared into a solution with a concentration of 0.01g / mL.

[0046] The raw material powder was added to the prepared solution, sealed with high-purity inert gas protection, magnetically stirred for 0.4h, and then ultrasonically treated in an ultrasonic cleaner for 0.3h to prepare a slurry with a solid-to-liquid ratio of 3.2g / mL.

[0047] Take out the prepared slurry and pre-mix with low melting point components 5wt.% HDPE, 5wt.% EVA and 8wt.% SA at a temperature of 130°C for 0.2h; then add high melting point components 82wt.% POM for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com