Preparation technology of low-smoke and halogen-free ceramic polyolefin refractory insulation material

A ceramic polyolefin, refractory insulation technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of limited application range, unfavorable scale-up production, low production efficiency, etc., and achieve excellent mechanical properties, development The effect of low smoke volume and high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

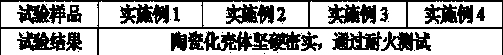

Examples

Embodiment 1~4

[0021] Embodiments 1-4: A preparation process for low-smoke and halogen-free ceramic polyolefin refractory insulating material, comprising the following steps:

[0022] Step 1: 30-50 parts of metallocene polyethylene, 30-50 parts of ethylene-α-octene copolymer, 10-20 parts of high-density polyethylene resin, 5-10 parts of amorphous polyolefin grafted with maleic anhydride, Pentaerythritol 10~20 parts, boron carbide 6~13 parts, silicon carbide 16~23 parts, nano aluminum hydroxide 60~80 parts, brucite 20~30 parts, talcum powder 10~20 parts, antioxidant 0.5~2 0.5-2 parts of silane coupling agent, 2-4 parts of sodium dodecylbenzene sulfonate, 2-6 parts of lubricant silicone masterbatch, all put into the internal mixer for mixing at one time, and the temperature of the mixing material is Discharge at 140~145°C;

[0023] Step 2. Feed the material obtained in step 1 into the conical feeding hopper, and then pass through the twin-screw extruder unit for plasticizing and extruding. Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com