Environmentally friendly brick surface anti-skid agent and preparation method thereof

An anti-slip agent and brick surface technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems of easy accumulation of oil in grooves, corrosion of sewer pipes, and attenuation of anti-slip effect, so as to achieve good grip, weaken acid corrosion, and improve The effect of surface friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

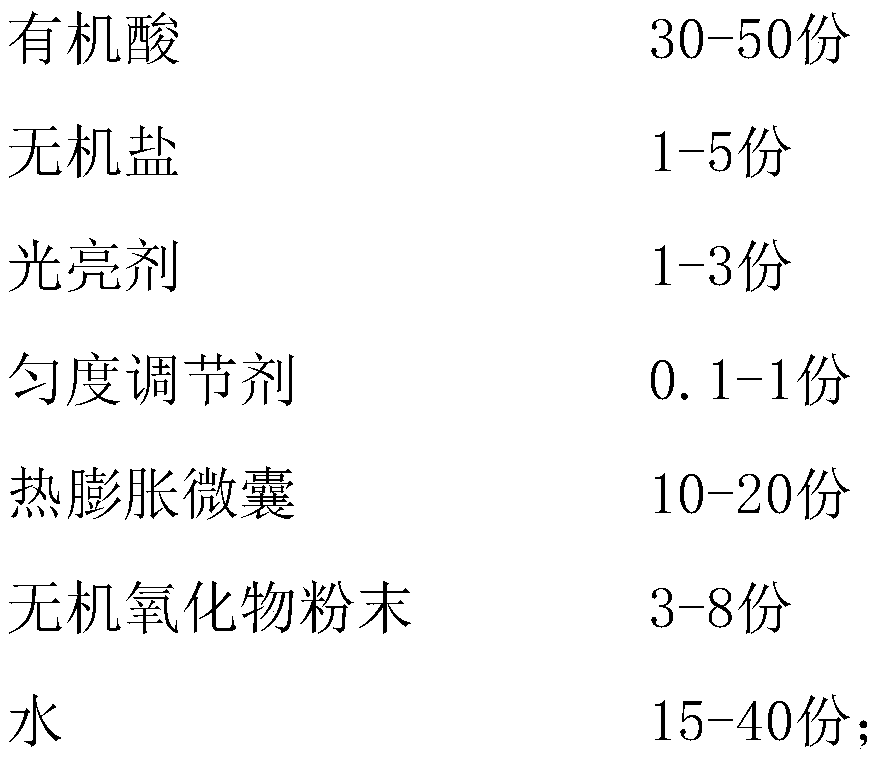

[0040] An environmental protection brick surface anti-skid agent comprises the following raw materials in parts by weight:

[0041]

[0042] Wherein, the particle size of the heat-expandable microcapsule is 28 μm, and the surface of the heat-expandable microcapsule is attached with nano-scale titanium dioxide powder.

[0043] The organic acid is obtained by mixing oxalic acid and citric acid extracted from plants in a weight ratio of 6:1.5.

[0044] The heat-expandable microcapsule has a hollow core-shell structure, the shell of the heat-expandable microcapsule is a thermoplastic polymer, the core of the heat-expandable microcapsule is a foaming agent, and the thickness of the shell of the heat-expandable microcapsule is 9 μm.

[0045] The foaming agent is formed by mixing n-hexane and n-heptane in a weight ratio of 1.5:7.

[0046] The preparation method of the heat-expandable microcapsules comprises the following steps:

[0047] (S1), take by weight 75 parts of acrylate ...

Embodiment 2

[0061] An environmental protection brick surface anti-skid agent comprises the following raw materials in parts by weight:

[0062]

[0063]

[0064] Wherein, the particle size of the heat-expandable microcapsule is 20 μm, and silicon dioxide powder is attached to the surface of the heat-expandable microcapsule.

[0065] The organic acid is formed by mixing oxalic acid and citric acid in a weight ratio of 5:2.

[0066] The heat-expandable microcapsule has a hollow core-shell structure, the shell of the heat-expandable microcapsule is a thermoplastic polymer, the core of the heat-expandable microcapsule is a foaming agent, and the thickness of the shell of the heat-expandable microcapsule is 3 μm.

[0067] The blowing agent is formed by mixing n-hexane and n-heptane at a weight ratio of 1:8.

[0068] The preparation method of the heat-expandable microcapsules comprises the following steps:

[0069] (S1), take by weight 50 parts of acrylate monomers, 30 parts of acrylic ...

Embodiment 3

[0083] An environmental protection brick surface anti-skid agent comprises the following raw materials in parts by weight:

[0084]

[0085]

[0086] Wherein, the particle size of the heat-expandable microcapsules is 35 μm, and the surface of the heat-expandable microcapsules is attached with nanoscale titanium dioxide powder.

[0087] The organic acid is formed by mixing oxalic acid and citric acid in a weight ratio of 8:1.

[0088] The heat-expandable microcapsule has a hollow core-shell structure, the shell of the heat-expandable microcapsule is a thermoplastic polymer, the core of the heat-expandable microcapsule is a foaming agent, and the thickness of the shell of the heat-expandable microcapsule is 15 μm.

[0089] The foaming agent is formed by mixing n-hexane and n-heptane in a weight ratio of 2:6.

[0090] The preparation method of the heat-expandable microcapsules comprises the following steps:

[0091] (S1), 100 parts by weight of acrylate monomer, 10 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com