Metal-doped indium sulfide nanosheets and preparation method and application thereof

A metal-doped, indium sulfide technology, applied in the field of its preparation, metal-doped indium sulfide nanosheets, can solve the problems of limited electronic regulation, complicated preparation process, unfavorable large-scale preparation, etc., to achieve excellent catalytic activity, The preparation process is simple and convenient, and the electronic structure can be adjusted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing metal-doped indium sulfide nanosheets, comprising: S1) mixing and reacting indium salt, doped metal salt and dialkyldithiocarbamate in an organic solvent to obtain a precursor body complexes; S2) heating the precursor complexes in an amine solvent to obtain metal-doped indium sulfide nanosheets.

[0037] In this application, there is no special limitation on the sources of all raw materials, as long as they are commercially available.

[0038] Wherein, the indium salt is preferably one or more of indium chloride, indium nitrate, indium sulfate and indium acetate; A salt compound of a heterometal, preferably one or more of ferrous salt, cobalt salt, nickel salt and manganese salt, more preferably nickel chloride, cobalt chloride, ferrous chloride, nickel nitrate, cobalt nitrate, One or more of ferrous nitrate, nickel acetate, cobalt acetate, ferrous acetate, nickel sulfate, cobalt sulfate, ferrous sulfate, manganese chloride...

Embodiment 1

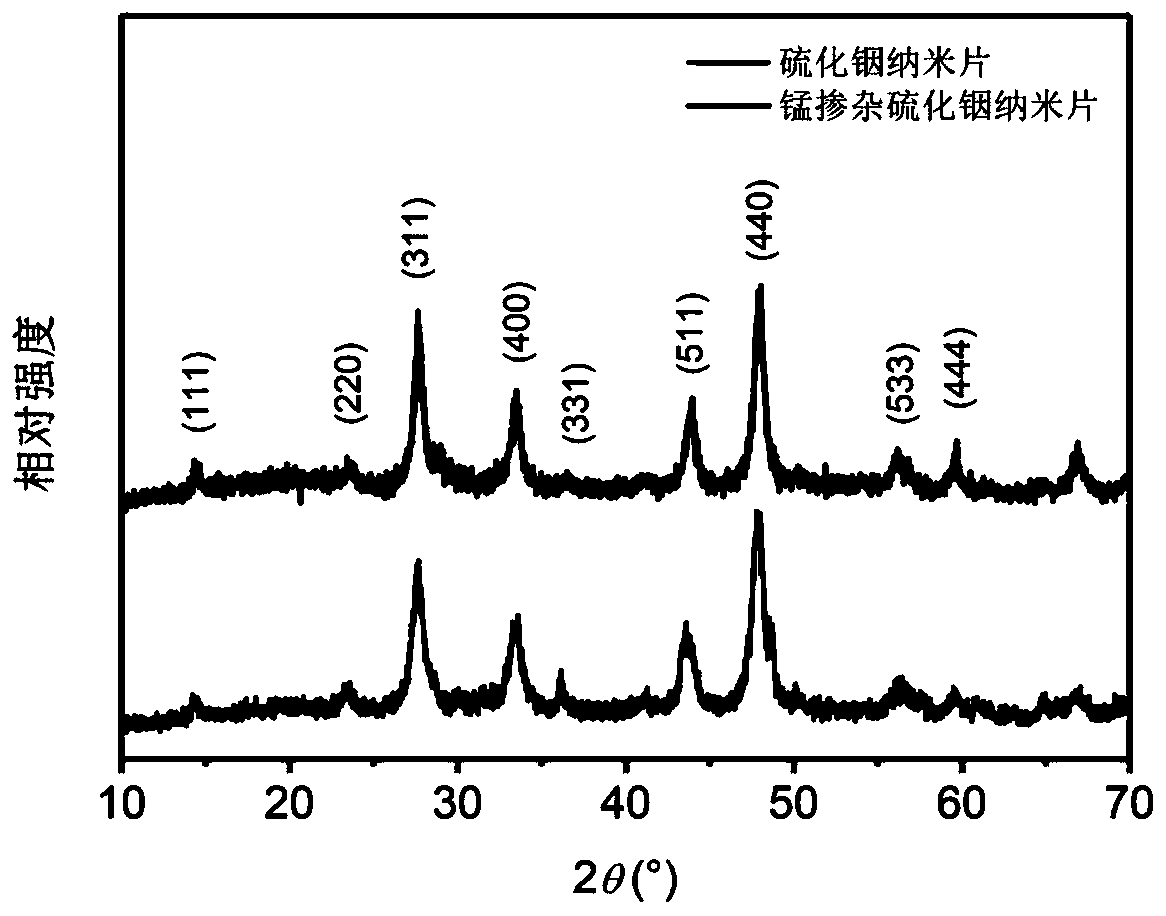

[0050] Dissolve 3mmol of sodium diethyldithiocarbamate in 10mL of methanol, add 5mL of methanol solution containing 1mmol of indium chloride and 0.03mmol of manganese chloride, stir well and place it at room temperature at 25°C for 120 minutes, then wash with ethanol , centrifuged, and dried to obtain the InMn-DDTC precursor.

[0051] Add 0.112g of InMn-DDTC precursor to 4g of dodecylamine, keep it airtight after blowing nitrogen for 15 minutes, heat to 200°C and keep it for 30 minutes, then rise to 300°C and keep it for 2 hours. After that, it was washed with acetone and chloroform, centrifuged, and dried to obtain Mn-In 2 S 3 ultrathin nanosheets.

[0052] The Mn-In that utilizes transmission electron microscope to obtain in embodiment 1 2 S 3 The ultra-thin nanosheets were detected, and the transmission electron microscope pictures were obtained as follows: figure 1 shown by figure 1 It can be seen that the Mn-In obtained in Example 1 2 S 3 The average size of the u...

Embodiment 2

[0055] Mn-In 2 S 3 Electrocatalyst and Electroreduction of Carbon Dioxide Test Conditions Using Ultrathin Nanosheets as Active Components.

[0056] 0.2mg Mn-In 2 S 3 Ultrathin nanosheets, 0.8 mg of activated carbon, and 15 μL of 5% Nafion solution were dispersed in 1 mL of ethanol, and ultrasonicated for 1 h to obtain a uniform solution. Then, take the above solution and brush evenly on 1cm×0.5cm carbon paper. The carbon paper was used as the working electrode, the silver / silver chloride electrode was used as the reference electrode, and the graphite rod was used as the counter electrode. The electrolytic solution for electroreduction of carbon dioxide reaction is 40mL potassium bicarbonate aqueous solution with a concentration of 0.1mol / L. Before the reaction, it is necessary to pass carbon dioxide for at least 30 minutes to drive away other gases. The catalytic reaction is carried out in an H-type electrolytic cell, which is separated by a Nafion 115 proton exchange mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com