Method for purifying silicon through phase separation and dealloying

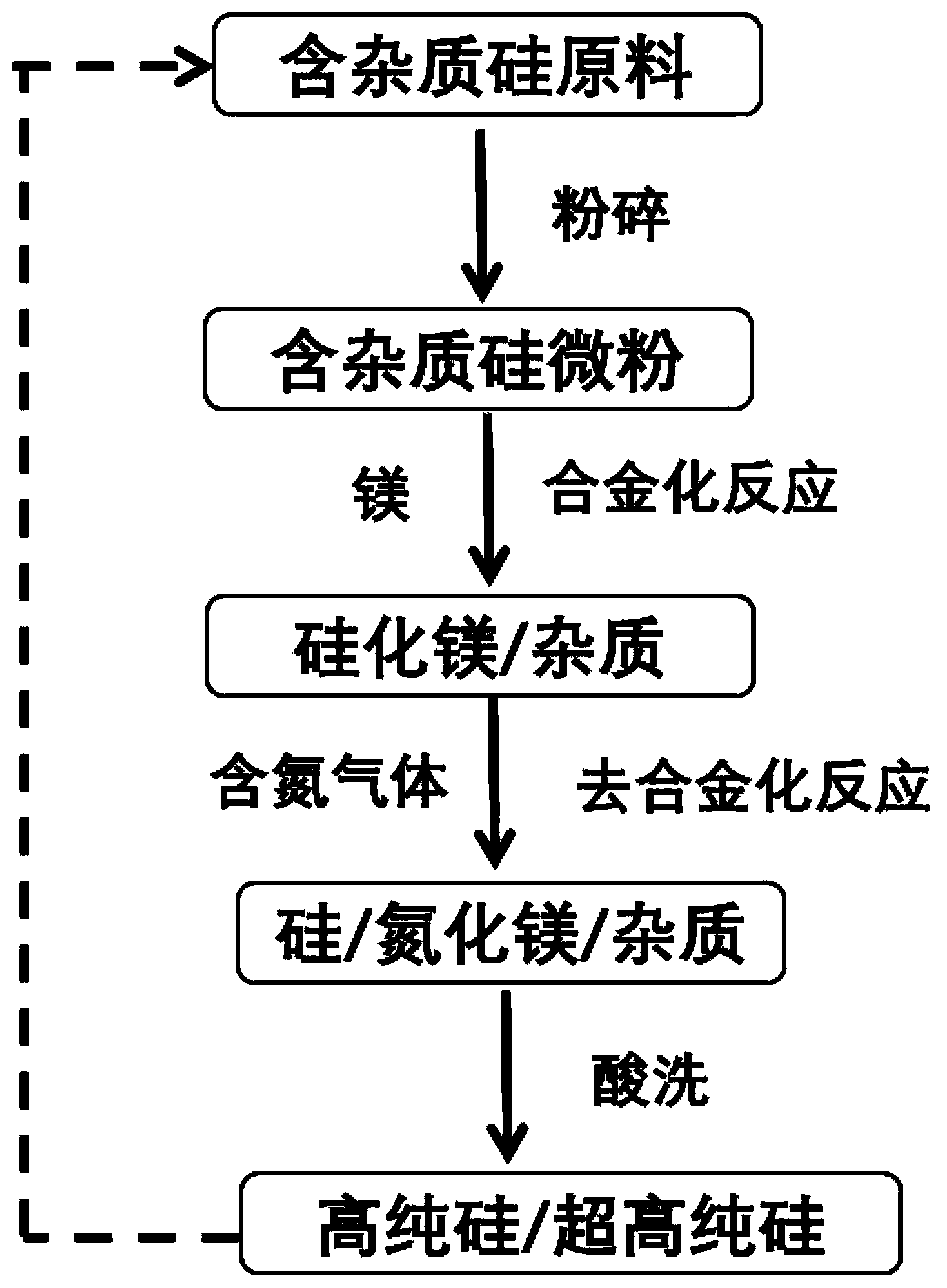

A dealloying and phase separation technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high cost, complex process, high energy consumption, etc., and achieve short cycle, high pollution, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for purifying silicon by phase separation dealloying, comprising the steps of:

[0052] (1) Mix metallurgical ferrosilicon powder (Si content is 80%) and magnesium powder according to the mass ratio of silicon and magnesium as 1:2 and put them into the high temperature resistant container;

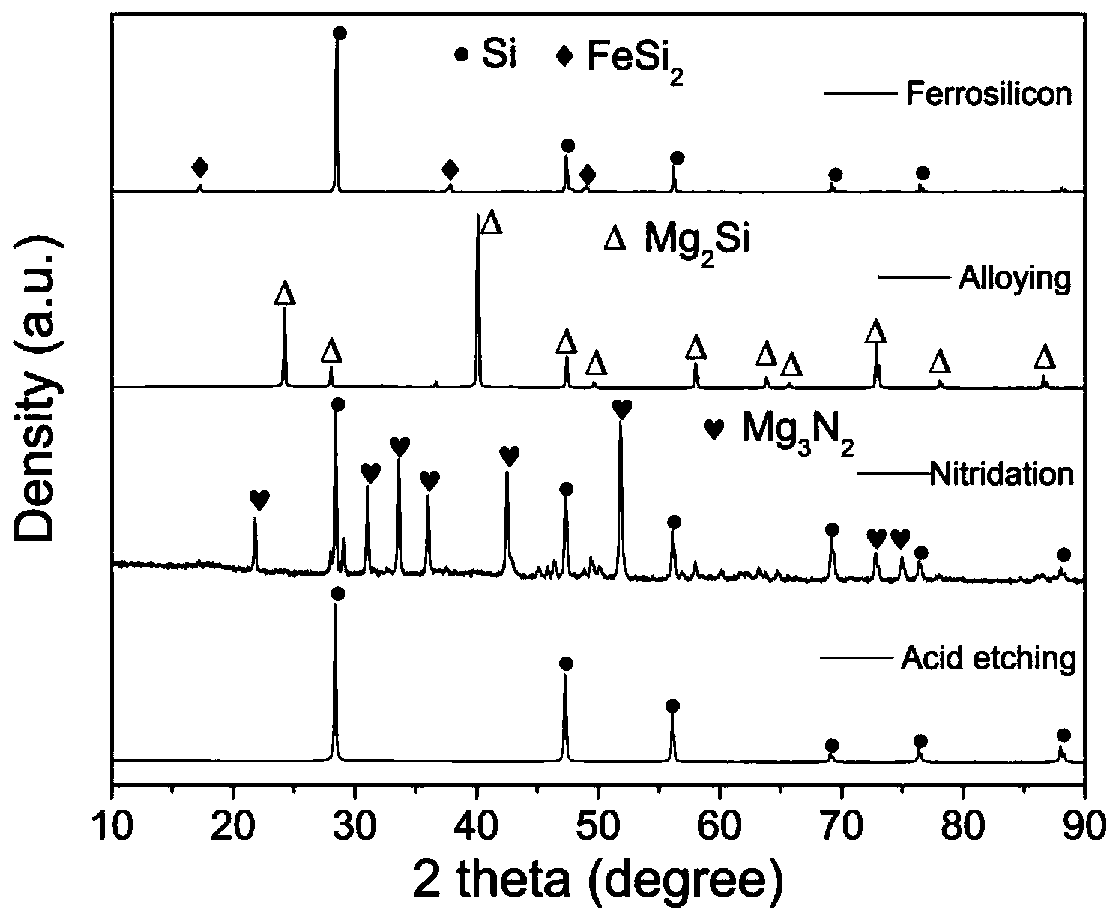

[0053] (2) Put the container in a tube furnace filled with inert gas and heat it up to 600°C at a heating rate of 5°C / min. The holding time is 6h to obtain the product silicon-magnesium alloy mixture. After the product is cooled to room temperature with the furnace, take it out;

[0054] (3) put the product obtained in (2) into N 2 In the atmosphere, heat up to 780°C at a heating rate of 5°C / min, hold for 4 hours, and take out the product after cooling to room temperature with the furnace;

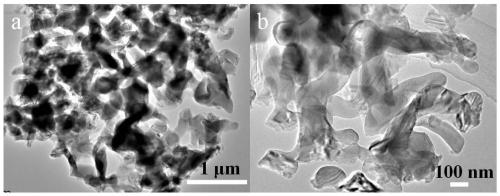

[0055] (4) Wash the product obtained in (3) with 1M hydrochloric acid to remove magnesium nitride, wash, centrifuge, and dry to obtain high-purity silicon. ICP test results show that ...

Embodiment 2

[0064] A method for purifying silicon by phase separation dealloying, comprising the steps of:

[0065] (1) Mix metallurgical ferrosilicon powder (Si content is 80%) and magnesium powder according to the mass ratio of silicon and magnesium at a ratio of 1:1.2 and put them in a high-temperature resistant container;

[0066] (2) Put the container in a tube furnace filled with inert gas and heat it to 500°C at a heating rate of 10°C / min. The holding time is 4h to obtain the product silicon-magnesium compound mixture. After the product is cooled to room temperature with the furnace, take it out;

[0067] (3) Put the product obtained in (2) into NH 3 In the atmosphere, heat up to 850°C at a heating rate of 3°C / min, hold for 6 hours, and take out the product after cooling to room temperature with the furnace;

[0068] (4) Wash the product obtained in (3) with 1M nitric acid to remove magnesium nitride, wash, centrifuge, and dry to obtain high-purity silicon with a purity of 99.15%....

Embodiment 3

[0070] A method for purifying silicon by phase separation dealloying, comprising the steps of:

[0071] (1) Put metallurgical ferrosilicon powder (with a Si content of 80%) and magnesium powder into a high-temperature-resistant container after being evenly mixed according to the mass ratio of silicon and magnesium at a ratio of 1:1.6;

[0072] (2) Put the container in a tube furnace filled with inert gas and heat it up to 650°C at a heating rate of 15°C / min. The holding time is 8h to obtain the product silicon-magnesium compound mixture. After the product is cooled to room temperature with the furnace, take it out;

[0073] (3) Put the product obtained in (2) into NH 3 In the atmosphere, heat up to 800°C at a heating rate of 10°C / min, hold for 5 hours, and take out the product after cooling to room temperature with the furnace;

[0074] (4) Wash the product obtained in (3) with 1M sulfuric acid to remove magnesium nitride, wash, centrifuge, and dry to obtain high-purity silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com