Method for preparing high-capacity hard carbon negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as high cost, difficult industrialization, and complicated processes, and achieve stable product properties, mild and controllable conditions, and simple preparation processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

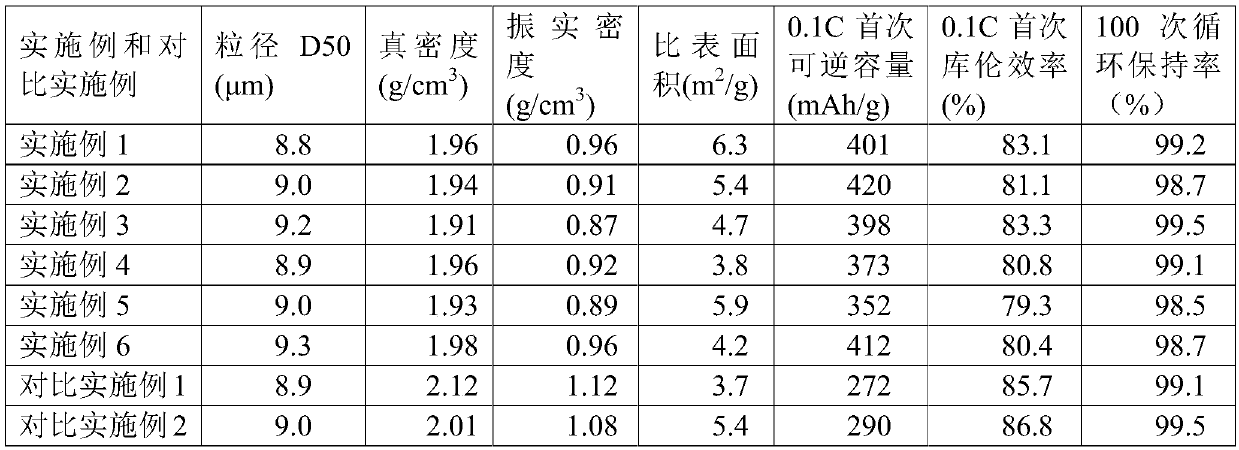

Examples

Embodiment 1

[0028] 1. The high-temperature petroleum asphalt with a softening point of 280°C is pulverized by an airflow milling classifier to make a powder with a volume average particle diameter D50 of 9 μm; in this example, the crushing method is preferably airflow milling, and the compressed air pressure of the airflow milling is 8~ 9Mpa, feeding frequency is 15~25Hz;

[0029] 2. Feed 1000g of the obtained asphalt powder and 100g of ammonium persulfate into the mixing mixer and mix the mixture for 5 minutes at a speed of 500r / min, then discharge to obtain the mixture;

[0030] 3. Place the obtained mixture in an air-blast drying oven at 80°C for 2 hours, then raise the temperature to 150°C and continue the reaction for 2 hours, and then discharge the mixture to obtain oxidized asphalt powder after cooling to room temperature;

[0031] 4. Then put it into the well-type furnace and raise the temperature to 600°C for 1 hour under the protection of nitrogen at 2°C / min, then cool down to r...

Embodiment 2

[0035] 1. The high-temperature petroleum asphalt with a softening point of 280°C is pulverized by a jet mill classifier to make a powder with a volume average particle size D50 of 9 μm;

[0036] 2. Feed 1000g of the obtained asphalt powder and 200g of ammonium persulfate into the mixing mixer and mix the mixture for 5 minutes at a speed of 500r / min, then discharge to obtain the mixture;

[0037] 3. Place the obtained mixture in a blast drying oven at 100°C for 2 hours, then raise the temperature to 200°C and continue the reaction for 2 hours, cool to room temperature and discharge to obtain oxidized asphalt powder;

[0038] 4. Then put it into the well-type furnace and raise the temperature to 600°C for 1 hour under the protection of nitrogen at 2°C / min, then cool down to room temperature and discharge;

[0039] 5. Then put it into an atmosphere furnace, raise the temperature to 1200°C for 1 hour under the protection of nitrogen at 2°C / min, cool down to room temperature and di...

Embodiment 3

[0041] 1. The high-temperature petroleum asphalt with a softening point of 280°C is pulverized by a jet mill classifier to make a powder with a volume average particle size D50 of 9 μm;

[0042] 2. Feed 1000g of the obtained asphalt powder and 1000g of hydrogen peroxide solution with a mass concentration of 20% into a mixer and mix at a speed of 500r / min for 20min, then discharge to obtain a slurry;

[0043] 3. Place the obtained slurry in an air-blast drying oven at 80°C for 2 hours, then raise the temperature to 110°C and continue the reaction for 4 hours, and then discharge to obtain oxidized asphalt powder after cooling to room temperature;

[0044] 4. Then put it into the well-type furnace and raise the temperature to 600°C for 1 hour under the protection of nitrogen at 2°C / min, then cool down to room temperature and discharge;

[0045] 5. Then put it into an atmosphere furnace, raise the temperature to 1200°C for 1 hour under the protection of nitrogen at 2°C / min, cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com