Package structure of dual-size cooling IPM hybrid module and processing technology

A technology of double-sided heat dissipation and packaging structure, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high power density, local heating, etc., and achieve the effects of improving service life, reducing the maximum temperature, and reducing bonding wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

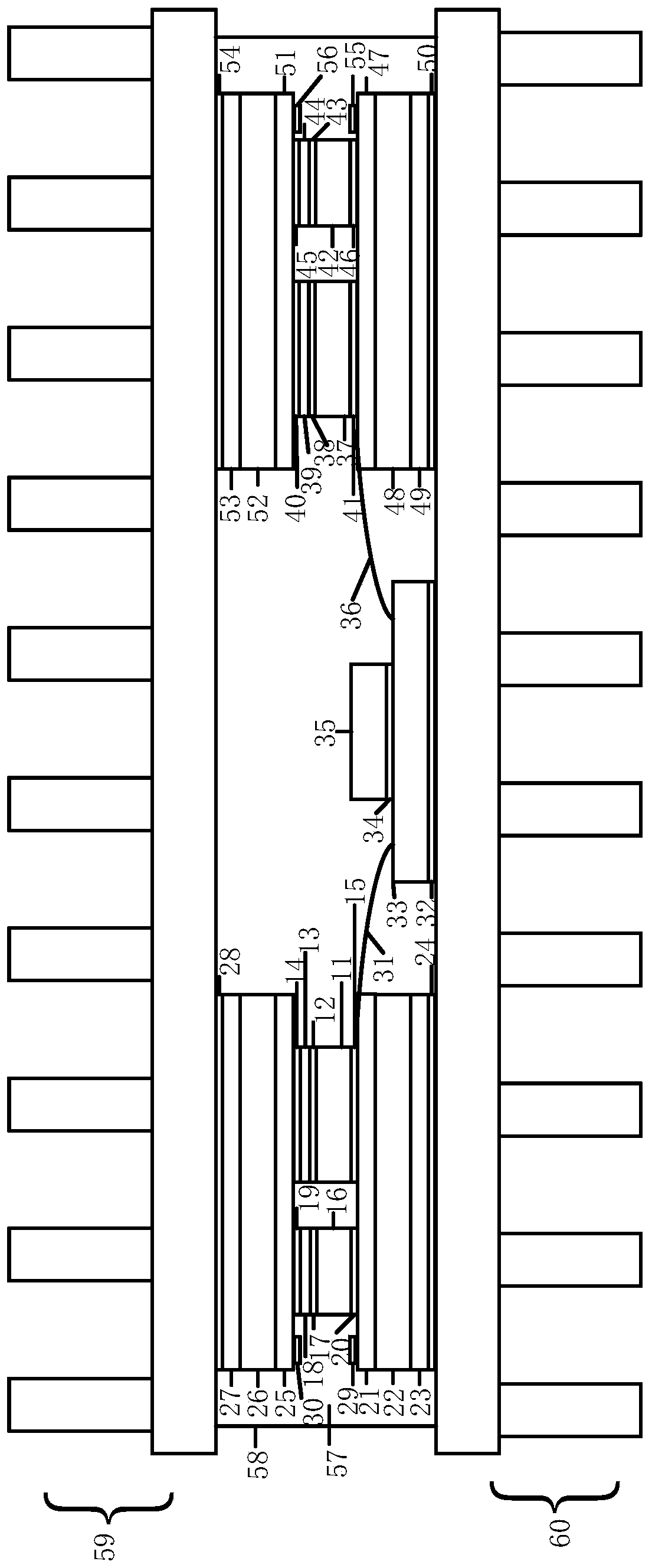

[0058] The present invention will be further described below in conjunction with drawings and embodiments.

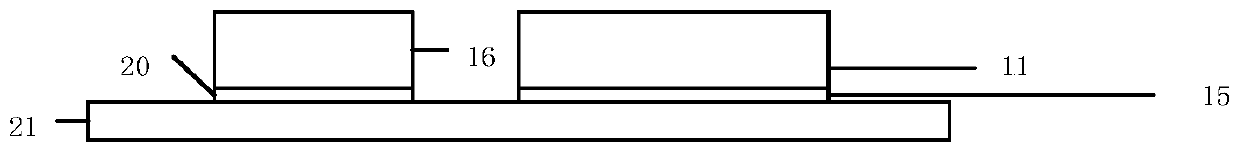

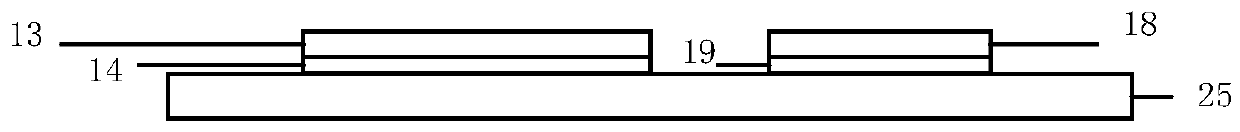

[0059] The present invention proposes a packaging structure of a double-sided heat dissipation IPM hybrid module, which generally includes a silicon-based IGBT chip, a SiC-based SBD chip (silicon carbide-based Schottky barrier diode chip), a silicon-based driver chip, and a printed circuit board (Printed Circuit Board). Board, PCB), DBC liner (that is, copper-clad ceramic substrate), nano-silver interconnection layer, buffer layer, solder layer, bonding wire, plastic package, packaging resin, thermal grease and heat sink. Wherein adopt upper and lower double radiator 59,60 to carry out double-sided cooling, see figure 1 . figure 1 The emitter of the first silicon-based IGBT chip 11 and the anode of the first SiC-based SBD chip 16 pass through the first nano-silver interconnect layer 15 and the third nano-silver interconnect layer 20, and are inverted mounted on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com