Preparation method for metallic uranium

A technology for metal uranium and U3O8, which is applied in the field of uranium preparation by molten salt electrochemical technology, which can solve the problems of reduced electrolysis efficiency, insufficient contact with electric current, and low solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

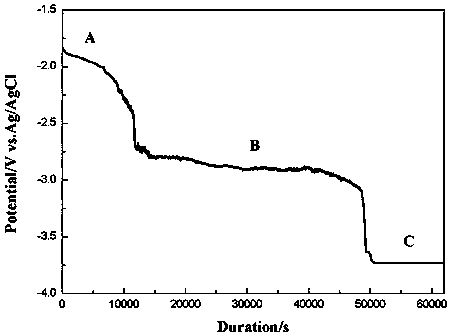

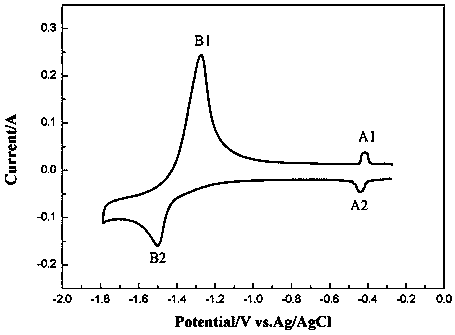

Image

Examples

Embodiment 1

[0039] A method for preparing uranium metal, comprising the steps of:

[0040] Step 1: Put 5g to 20g of U3O8 into a tube furnace, feed high-purity nitrogen gas for 30-300min, heat U3O8 at 100°C for 1 hour, and then heat U3O8 at 250°C for 1 hour ; The temperature of the debugging water bath is 85 degrees Celsius, the carbon tetrachloride in the heating flask is mixed with carbon tetrachloride gas and high-purity nitrogen, and the mixed gas flow rate is 3cm 3 / min, the mixed gas is passed into the quartz tube, and the temperature of the quartz tube is raised to 400-460 degrees Celsius, and heated for 2-6 hours. After the reaction is completed, the tube furnace is opened to cool down immediately, and the porcelain boat is taken out to obtain the powder product A (A is uranium tetrachloride);

[0041] Step 2: Place 4g to 12g of powdered product A on the bottom of the crucible, pour 100-300g of LiCl and KCl mixed molten salt with a mass content of 99%-99.99%, the mass ratio of LiC...

Embodiment 2

[0044] A method for preparing uranium metal, the present embodiment is basically the same as embodiment 1, the difference is that in step 2, the spectroscopically pure graphite rod is used as an auxiliary electrode, and the molybdenum sheet is used as a working electrode, and the electrolysis temperature is 873K; in step 3, the size 2cm*2cm, molybdenum sheet with a thickness of 0.2cm is used as the cathode, and electrolyzed at 0.1A-1A for 1-40 hours.

Embodiment 3

[0046] A method for preparing uranium metal. This embodiment is basically the same as Embodiment 1, except that in step 2, the electrolysis temperature is 873K.

[0047] Technical Note: By adjusting the temperature parameters and providing additional heat, the electrolysis reaction time will be less than 17.05 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com