Fe-Mn-Cr-Ni-series medium-entropy stainless steel and preparation method thereof

A fe-mn-cr-ni, stainless steel technology, applied in the field of Fe-Mn-Cr-Ni series entropy stainless steel and its preparation, can solve the problems of high economic cost and difficult industrialized production, achieve improved service life, excellent The effect of seawater corrosion resistance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

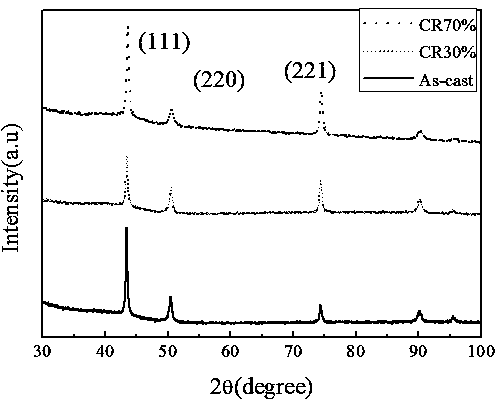

[0030] This embodiment is a Fe-Mn-Cr-Ni medium-entropy stainless steel composed of four elements: Fe, Mn, Cr, and Ni, and the atomic percentages of Fe, Mn, Cr, and Ni elements are 40%: 20%: 20%: 20%. The raw materials for preparation are pure Fe, pure Ni, pure Cr and FeMn binary alloy with an atomic ratio of 1:1.

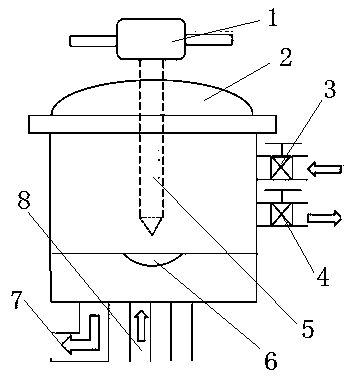

[0031] A preparation method of Fe-Mn-Cr-Ni series medium entropy stainless steel, comprising the following steps:

[0032] Step 1. Pretreatment: use a grinder to polish the surface oxide scales with high-purity (≥99.99%) Fe, Ni and Cr and Fe-Mn binary alloys with an atomic ratio of 1:1, and then place them in the In a beaker with absolute ethanol, perform ultrasonic treatment for 10 minutes to remove impurities and dirt on the surface of the raw materials, and then place the above raw materials in a drying oven for drying;

[0033] Step 2. Weighing materials: Prepare according to the atomic percentages of Fe, Mn, Cr, and Ni elements in order of 40%: 20%: 20%: 20%,...

Embodiment 2

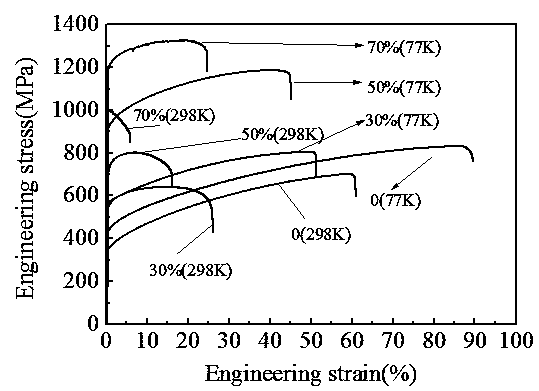

[0048] Embodiment 2: Cut the sample processed in Step 4 of Embodiment 1 into three standard tensile patterns by wire cutting, the length of the gauge section is about 10mm, and the width is 3mm. Then use 240#, 600#, 800#, 1000#, 1200#, 1500#, 2000# to carry out mechanical grinding respectively to ensure that the gauge length section is flat, the scratch direction is consistent and there are no macro defects. Static and low-temperature tensile experiments, the strain rate during the experiment was 1×10-3 / s, in order to ensure the accuracy and repeatability of the experimental results, at least 3 samples were tested for each material, and finally the data with similar results were selected to use Origin8. 0 software to draw tensile engineering stress-strain curves. From the tensile engineering stress-strain curve, it can be clearly seen that the yield strength of the sample after step 4 treatment has been significantly improved compared with the as-cast state, which is 3 times t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com